3823579

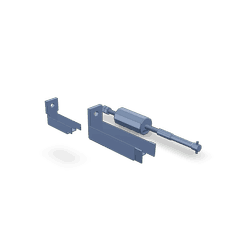

Injector i And r Assembly

Cummins®

BACK ORDERED

Please contact us for information on lead time

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

Injectors are vital for the performance of commercial truck engines, ensuring efficient fuel delivery and combustion. Cummins, a leader in the diesel engine industry, manufactures high-quality components designed to enhance engine performance and reliability. This article provides a comprehensive understanding of the Cummins Injector I And R Assembly (Part #3823579), its function, integration, and maintenance.

Basic Concepts Related To Injector I And R Assembly

Fuel injectors are crucial in diesel engines, delivering precise amounts of fuel into the combustion chamber at the right time. The Cummins Injector I And R Assembly comprises several key components: the nozzle, solenoid, body, and return spring. Each part plays a specific role in the fuel injection process, ensuring optimal engine performance 1.

How The Cummins Injector I And R Assembly Works

The operation of this Cummins part is a finely tuned process. When the engine’s control unit signals the solenoid, it opens the injector, allowing high-pressure fuel to spray through the nozzle into the combustion chamber. The return spring ensures the injector closes promptly after fuel delivery, maintaining precise timing and pressure. This meticulous process is crucial for engine efficiency and emissions control 2.

Purpose Of The Cummins Injector I And R Assembly In Truck Engines

The Cummins Injector I And R Assembly significantly contributes to the engine’s power output and fuel efficiency. By ensuring proper fuel atomization, it helps reduce emissions, aligning with environmental regulations. Its reliability and durability are essential for heavy-duty applications, where consistent performance under demanding conditions is paramount 3.

Troubleshooting The Cummins Injector I And R Assembly

Common issues with this part include clogging, leaking, and electrical faults. Diagnostic techniques such as visual inspections, pressure tests, and electrical checks can identify problems. Regular maintenance and cleaning can often resolve minor issues, but in cases of significant wear or damage, replacement may be necessary.

Maintenance Tips For The Cummins Injector I And R Assembly

To ensure the longevity and performance of the Cummins Injector I And R Assembly, regular inspection and cleaning are vital. Using high-quality fuel and filters prevents contaminants from damaging the injector. Proper storage and handling practices, such as keeping injectors clean and dry when not in use, also contribute to their reliability. Maintenance frequency should be based on the engine’s usage and operating conditions.

Cummins: A Leader In Diesel Engine Technology

Cummins has a rich history of innovation in the diesel engine industry. Their commitment to quality and reliability is evident in every product they manufacture. Cummins continues to lead in advancing diesel engine technology, focusing on sustainability and efficiency.

Expert Insights And Best Practices

Industry experts emphasize the importance of optimizing injector performance through regular maintenance and using the latest technology. Integrating injector maintenance into fleet operations ensures consistent engine performance and reduces downtime. Case studies of successful injector maintenance programs highlight the benefits of proactive care.

Conclusion

Proper maintenance of the Cummins Injector I And R Assembly is crucial for engine longevity and performance. By understanding its function, troubleshooting common issues, and following best practices for maintenance, engineers and mechanics can ensure their fleets operate efficiently and reliably. Applying this knowledge will lead to better engine performance and reduced maintenance costs.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.