This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3802328 Injector is a critical component designed for use in commercial trucks, specifically within Cummins engines. It plays a significant role in the fuel delivery system, ensuring efficient combustion and optimal engine performance. Understanding its function and importance can help in maintaining and optimizing the overall operation of the vehicle.

Basic Concepts of Fuel Injectors

Fuel injectors are devices that deliver fuel into an engine’s combustion chamber. They operate by atomizing fuel into a fine mist, which mixes with air before combustion. This process enhances fuel efficiency and reduces emissions. In internal combustion engines, fuel injectors replace carburetors, offering more precise control over fuel delivery and improving engine performance 1.

Purpose of the Cummins 3802328 Injector

The Cummins 3802328 Injector is specifically engineered to deliver fuel into the combustion chamber of Cummins engines found in commercial trucks. It ensures that fuel is atomized and distributed evenly, which is vital for consistent combustion and engine efficiency. This injector maintains the correct fuel-to-air ratio, which is essential for engine performance and emissions control 2.

Key Features

The Cummins 3802328 Injector boasts several key features that enhance its functionality. Its design incorporates advanced technology to ensure precise fuel delivery. The materials used in its construction are durable, ensuring longevity and reliability. Additionally, it includes technological advancements such as improved nozzle design and enhanced electronic controls, which contribute to better fuel atomization and combustion efficiency 3.

Benefits

The Cummins 3802328 Injector offers several benefits. It contributes to improved fuel efficiency by ensuring that fuel is delivered in the most effective manner possible. This results in better overall engine performance and reduced fuel consumption. Additionally, the injector’s reliable design and construction enhance the durability and longevity of the engine, providing consistent performance over time.

Installation and Integration

Proper installation of the Cummins 3802328 Injector is vital for ensuring optimal performance. The installation process requires specific tools and equipment to ensure that the injector is securely fitted and properly aligned within the fuel system. Following manufacturer guidelines during installation helps prevent issues and ensures that the injector functions as intended.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3802328 Injector is important for ensuring its continued performance. This includes regular cleaning and inspection to prevent buildup and ensure that the injector operates efficiently. Troubleshooting common issues, such as poor fuel delivery or misfires, often involves checking the injector for clogs or damage and ensuring that it is properly seated within the fuel system.

Performance Optimization

Optimizing the performance of the Cummins 3802328 Injector can be achieved through various strategies. This may include tuning the engine to ensure that the injector operates within its optimal parameters. Additionally, upgrades such as high-performance nozzles or electronic control enhancements can further improve fuel delivery and combustion efficiency.

Safety Considerations

When working with the Cummins 3802328 Injector, it is important to follow safety precautions. This includes proper handling to avoid damage to the injector and ensuring that it is stored in a safe environment. Additionally, understanding the potential hazards associated with fuel systems, such as flammability and pressure, is crucial for safe operation and maintenance.

Environmental Impact

The Cummins 3802328 Injector plays a role in reducing emissions by ensuring efficient fuel combustion. This contributes to lower levels of harmful pollutants being released into the atmosphere. Additionally, its design and function support the overall goal of promoting sustainability within the commercial trucking industry by enhancing fuel efficiency and reducing the environmental footprint of these vehicles.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to innovation and quality. With a rich history in the industry, Cummins has established a reputation for producing reliable and high-performance engine components. The company’s dedication to advancing technology and improving engine efficiency underscores its role in the commercial trucking sector.

Cummins Injector 3802328 Compatibility

The Cummins Injector part number 3802328 is a critical component in the fuel injection system of various diesel engines. This injector is designed to precisely meter and deliver fuel into the combustion chamber, ensuring optimal performance and efficiency. Below is a detailed description of how this injector fits with specific Cummins engines.

6B5.9 Engine

The Cummins 6B5.9 engine is a robust and reliable powerplant often found in heavy-duty applications such as construction equipment, agricultural machinery, and industrial generators. The injector 3802328 is specifically engineered to work seamlessly with the 6B5.9 engine, providing the necessary fuel delivery for its demanding operational requirements.

Grouping of Engines

For engines within the same family or series, the injector 3802328 may also be compatible with other variants. This compatibility is due to shared design principles and engineering standards that ensure interchangeability and reliability across similar engine models.

Ensuring Proper Fitment

When installing the Cummins injector 3802328, it is crucial to follow the manufacturer’s guidelines to ensure proper fitment and function. This includes:

- Correct Torque Specifications: Ensuring the injector is tightened to the specified torque to avoid leaks and maintain performance.

- Proper Sealing: Using the correct o-rings and seals to prevent fuel and oil contamination.

- Alignment: Ensuring the injector is aligned correctly within the fuel injector rail to maintain uniform fuel delivery across all cylinders.

By adhering to these guidelines, the injector 3802328 will perform optimally, contributing to the overall efficiency and longevity of the engine.

Role of Part 3802328 Injector in Engine Systems

The injector, specifically part 3802328, is integral to the efficient operation of engine systems. It works in concert with various components to ensure optimal fuel delivery and combustion.

Fuel Rail Integration

The injector is mounted on the fuel rail, a component that distributes pressurized fuel to each cylinder. The precise placement and secure fitting of the injector on the fuel rail are essential for maintaining consistent fuel pressure across all cylinders.

Throttle Body and Air Intake System

As air enters the engine through the throttle body and air intake system, the injector times the fuel spray to coincide with the intake stroke. This synchronization ensures a proper air-fuel mixture, which is vital for combustion efficiency and overall engine performance.

Engine Control Unit (ECU) Communication

The injector relies on signals from the Engine Control Unit (ECU) to determine the timing and duration of fuel injection. The ECU monitors various parameters such as engine load, RPM, and oxygen sensor readings to make real-time adjustments, ensuring the injector delivers the precise amount of fuel needed for optimal performance.

Combustion Chamber Interaction

Once the fuel is injected into the combustion chamber, it mixes with the compressed air. The injector’s design and spray pattern are optimized to promote thorough mixing, leading to more complete combustion and reduced emissions.

Exhaust System Impact

The efficiency of the injector directly influences the composition of the exhaust gases. A well-timed and properly atomized fuel spray results in cleaner combustion, which in turn reduces the workload on the catalytic converter and other exhaust system components.

Performance Parts Synergy

When paired with performance parts such as upgraded turbos, intercoolers, or camshafts, the injector plays a pivotal role in handling the increased fuel demands. Its ability to deliver fuel precisely when needed supports the enhanced performance capabilities of these aftermarket components.

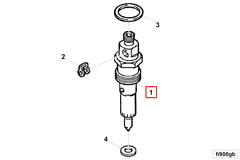

Components of Cummins Injector Kit 3802328

Rectangular Ring Seal (3909356)

The rectangular ring seal is a critical component in the Cummins injector kit 3802328. Its primary function is to ensure a secure and leak-proof connection between various parts of the injector assembly. The seal is designed to withstand high pressures and temperatures, providing reliable performance and longevity. It plays a pivotal role in maintaining the integrity of the injector system by preventing fuel leaks and ensuring efficient fuel delivery.

Injector (3919304)

The injector (3919304) is the core component of the Cummins injector kit 3802328. It is responsible for delivering precisely metered amounts of fuel into the combustion chamber at the right time. The injector’s design ensures optimal fuel atomization, which is crucial for efficient combustion and overall engine performance. This component is engineered to meet stringent performance standards, ensuring consistent and reliable operation under various operating conditions.

Injector Sleeve (3919358)

The injector sleeve (3919358) serves as a protective and guiding element within the injector assembly. It houses the injector and provides a smooth surface for its operation. The sleeve is designed to withstand the high pressures and temperatures encountered during fuel injection, ensuring durability and reliability. Additionally, it helps in maintaining the alignment and stability of the injector, contributing to the overall efficiency and performance of the injection system.

Banjo Connector Seal (4942278)

The banjo connector seal (4942278) is an essential component that ensures the integrity of the fuel supply line connections within the injector kit. It is designed to create a secure and leak-proof seal between the banjo fitting and the fuel line. This seal is critical in preventing fuel leaks, which could lead to performance issues and safety hazards. The banjo connector seal is made from high-quality materials to endure the harsh conditions within the engine compartment, ensuring reliable and consistent performance.

Conclusion

The Cummins 3802328 Injector is a vital component in the fuel delivery system of Cummins engines, ensuring efficient combustion and optimal engine performance. Its advanced design, precise fuel delivery, and compatibility with various Cummins engines make it a reliable choice for commercial truck applications. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing its benefits and ensuring the longevity and efficiency of the engine.

-

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.