This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

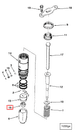

The Cummins Injector Cup, identified by Part #3202078, is a critical component in the fuel injection system of heavy-duty trucks. This part facilitates the efficient and reliable delivery of fuel to the engine, ensuring optimal performance and longevity of the vehicle. The significance of the Injector Cup lies in its role in maintaining the integrity of the fuel injection process, which is vital for the overall operation of the truck 3.

Basic Concepts and Functionality

Injector cups are specialized components within the fuel injection system that house the fuel injector tip. They operate by providing a secure and sealed environment for the injector, allowing it to deliver fuel into the combustion chamber under high pressure. The Injector Cup interacts closely with other components such as the cylinder head and fuel injectors, ensuring that fuel is delivered precisely when needed for combustion 4.

Purpose and Role in Truck Operation

The Cummins Injector Cup plays a significant role in the fuel injection system by maintaining fuel pressure, sealing the injector, and ensuring efficient fuel delivery. It helps in creating a high-pressure environment necessary for the fuel to atomize properly upon injection, which is crucial for efficient combustion. Additionally, the Injector Cup prevents fuel leakage, which could lead to performance issues and potential engine damage 1.

Key Features

The Cummins Injector Cup is designed with several key features that contribute to its performance and durability. It is typically made from high-strength materials to withstand the extreme pressures and temperatures within the engine. Design enhancements may include improved sealing surfaces and robust construction to ensure longevity and reliability under demanding conditions 2.

Benefits

Using the Cummins Injector Cup offers several benefits. It contributes to improved engine performance by ensuring precise fuel delivery and maintaining optimal fuel pressure. Enhanced fuel efficiency is another advantage, as the Injector Cup helps in achieving better fuel atomization, leading to more complete combustion. Additionally, the reliability of the Injector Cup in heavy-duty applications ensures consistent engine operation and reduces the likelihood of fuel system failures 3.

Installation and Maintenance

Proper installation of the Cummins Injector Cup is crucial for ensuring optimal performance and longevity. It should be installed according to the manufacturer’s guidelines, which may include torquing to specific specifications to ensure a proper seal. Regular maintenance practices, such as inspecting for wear and ensuring there are no leaks, are recommended to maintain the Injector Cup’s effectiveness. Following these guidelines helps in preventing potential issues and ensures the component continues to function as intended 4.

Troubleshooting Common Issues

Common problems associated with injector cups include leaks or failures, which can lead to decreased engine performance or increased emissions. Troubleshooting steps may involve inspecting the Injector Cup for signs of wear or damage, checking the sealing surfaces for proper contact, and ensuring that the installation torque specifications were met. Addressing these issues promptly can help in maintaining the efficiency and reliability of the fuel injection system 1.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has a long history of producing high-quality engine components and systems. The company is known for its commitment to innovation, quality, and customer satisfaction, making it a trusted name in the industry for reliable and durable automotive parts 2.

Compatibility of Cummins Injector Cup 3202078

The Cummins Injector Cup, part number 3202078, is a critical component in the fuel injection system of various engines. This part is engineered to ensure efficient fuel delivery and combustion, which is essential for the optimal performance of the engine. Here is a detailed overview of the engines and engine groups where this injector cup is compatible:

L10 MECHANICAL Engines

The Cummins Injector Cup 3202078 is specifically designed to fit the L10 MECHANICAL engines. These engines are known for their robust construction and reliability, making them a popular choice in various industrial applications. The injector cup plays a vital role in these engines by ensuring that fuel is delivered precisely and consistently to the combustion chamber, which is crucial for maintaining engine efficiency and performance 3.

Engine Groups

The injector cup 3202078 is compatible with several engine groups that utilize the L10 MECHANICAL engine as their base. These engine groups are designed to meet the needs of different applications, from heavy-duty trucks to industrial machinery. The compatibility of the injector cup with these engine groups ensures that the fuel injection system operates smoothly, contributing to the overall reliability and efficiency of the engine 4.

Industrial Applications

In industrial settings, the L10 MECHANICAL engines equipped with the Cummins Injector Cup 3202078 are often used in applications that require consistent and reliable performance. These engines are found in various sectors, including construction, agriculture, and power generation. The injector cup’s role in these engines is to provide a precise and efficient fuel delivery system, which is essential for maintaining the high standards of performance expected in these demanding environments 1.

Heavy-Duty Trucks

The Cummins Injector Cup 3202078 is also compatible with L10 MECHANICAL engines used in heavy-duty trucks. These engines are designed to handle the rigors of long-haul transportation, where reliability and efficiency are paramount. The injector cup ensures that the fuel injection system operates flawlessly, contributing to the engine’s ability to deliver consistent power and performance over long distances 2.

Power Generation

In power generation applications, the L10 MECHANICAL engines equipped with the Cummins Injector Cup 3202078 are used to provide a stable and reliable source of power. These engines are often found in backup power systems, where they need to start and run efficiently under various conditions. The injector cup plays a crucial role in these engines by ensuring that fuel is delivered accurately and consistently, which is essential for maintaining the engine’s performance and reliability 3.

Marine Applications

The Cummins Injector Cup 3202078 is also compatible with L10 MECHANICAL engines used in marine applications. These engines are designed to withstand the harsh marine environment, where they need to operate reliably and efficiently. The injector cup ensures that the fuel injection system functions smoothly, contributing to the engine’s ability to deliver consistent power and performance in challenging marine conditions 4.

Role of Part 3202078 Injector Cup in Engine Systems

The 3202078 Injector Cup is an integral component within the fuel injection system of an engine. Its primary function is to provide a secure and leak-proof seal for the injector within the cylinder head. This ensures that fuel is delivered precisely and efficiently to the combustion chamber 1.

Interaction with Injector

The Injector Cup directly interfaces with the fuel injector, holding it in place while withstanding the high pressures and temperatures generated during fuel injection. This interaction is vital for maintaining the integrity of the fuel delivery system, ensuring that fuel is injected at the correct pressure and timing 2.

Contribution to Performance Parts

In the context of performance parts, the 3202078 Injector Cup plays a significant role. High-performance engines often demand higher fuel pressures and more precise fuel delivery. The Injector Cup must be able to handle these increased demands without failing, thus contributing to the overall reliability and performance of the engine 3.

Sealing and Pressure Management

One of the key functions of the Injector Cup is to create a robust seal that prevents fuel leakage into the cylinder head. This seal is essential for maintaining consistent fuel pressure and preventing contamination of the engine oil with fuel, which can lead to decreased lubrication efficiency and potential engine damage 4.

Thermal Management

The Injector Cup also aids in thermal management within the engine. By providing a barrier between the high-temperature combustion chamber and the cooler fuel system, it helps to maintain optimal operating temperatures for both the injector and the surrounding components 1.

Integration with Cylinder Head

The design of the Injector Cup allows it to be securely integrated into the cylinder head, ensuring that it remains in place under the extreme conditions of engine operation. This integration is crucial for the consistent performance of the fuel injection system 2.

Support for Fuel System Components

Beyond its direct interaction with the injector, the Injector Cup supports other fuel system components by ensuring a stable and secure environment for fuel delivery. This stability is essential for the precise operation of modern fuel injection systems, which rely on accurate fuel metering for optimal engine performance 3.

Conclusion

In summary, the 3202078 Injector Cup is a fundamental component that enhances the functionality and reliability of the fuel injection system within an engine. Its role in sealing, pressure management, thermal management, and integration with other components underscores its importance in both standard and high-performance engine applications 4.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ ↩ ↩ ↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ ↩ ↩ ↩ ↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ ↩ ↩ ↩ ↩ ↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.