This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

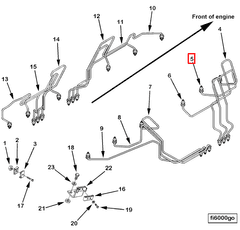

The Injector Fuel Supply Tube (Part #3094872) manufactured by Cummins is a critical component in the fuel system of heavy-duty trucks. It ensures efficient engine performance by facilitating the delivery of fuel from the tank to the injectors. This part is designed to maintain optimal fuel pressure and consistent fuel delivery, which are essential for the engine’s operation 1.

Function and Operation

The Injector Fuel Supply Tube operates within the fuel system by delivering fuel from the tank to the injectors. It maintains fuel pressure and ensures a steady supply of fuel to the engine. This consistent delivery is vital for the engine’s combustion process, allowing it to run smoothly and efficiently. The tube is engineered to withstand the pressures and temperatures within the fuel system, ensuring reliable performance 2.

Key Features

The Injector Fuel Supply Tube is characterized by its durable construction and precise engineering. It is made from high-quality materials that can endure the harsh conditions of heavy-duty truck operations. The design of the tube ensures compatibility with Cummins engines, providing a seamless fit and function. Its construction includes robust materials that resist wear and corrosion, enhancing its longevity and reliability.

Benefits

The Injector Fuel Supply Tube offers several benefits, including improved fuel efficiency and enhanced engine performance. By ensuring consistent fuel delivery and maintaining optimal fuel pressure, it contributes to the engine’s efficiency. Additionally, the tube’s design reduces the risk of fuel leaks, enhancing safety and reliability. Its robust construction ensures durability in demanding operating conditions, making it a reliable component for heavy-duty applications.

Installation and Compatibility

Proper installation of the Injector Fuel Supply Tube is vital for its effective function. Recommended procedures and tools should be used to ensure a secure and correct fit. The tube is compatible with various Cummins engine models, ensuring it can be integrated into different systems without issues. It is also designed to work with other relevant components, providing a cohesive fuel delivery system.

Maintenance and Troubleshooting

To ensure the optimal performance and longevity of the Injector Fuel Supply Tube, regular maintenance is recommended. This includes checking for signs of wear, corrosion, or damage. Common issues such as fuel leaks or blockages can often be addressed through routine inspections and cleaning. If problems arise, troubleshooting steps should include verifying connections, inspecting for damage, and ensuring the tube is properly seated within the system.

Safety Considerations

When working with the Injector Fuel Supply Tube, it is important to adhere to safety precautions and best practices. This includes proper handling of the fuel system, use of personal protective equipment, and following manufacturer guidelines. Ensuring that the system is depressurized before any work is performed can prevent accidents and ensure a safe working environment.

Environmental Impact

The Injector Fuel Supply Tube plays a role in reducing emissions and promoting fuel efficiency in heavy-duty trucks. By ensuring consistent and efficient fuel delivery, it helps the engine operate more cleanly and efficiently. This not only enhances performance but also contributes to lower emissions, aligning with environmental considerations in the automotive industry.

Cummins Corporation

Cummins Corporation is a renowned name in the automotive industry, known for its commitment to innovation and quality in manufacturing automotive components. With a rich history and a strong reputation, Cummins continues to lead in the development of reliable and efficient engine components. Their dedication to excellence is evident in the design and performance of the Injector Fuel Supply Tube, reflecting their ongoing commitment to quality and innovation 3.

Cummins Injector Fuel Supply Tube (Part 3094872) Compatibility

The Cummins Injector Fuel Supply Tube, identified by part number 3094872, is a critical component in the fuel delivery system of various Cummins engines. This part ensures the proper flow of fuel from the fuel supply system to the injectors, maintaining optimal engine performance and efficiency.

QST30 CM552 Engines

The Injector Fuel Supply Tube (3094872) is specifically designed to fit seamlessly with the QST30 CM552 engines. These engines are known for their robust construction and reliability, often used in heavy-duty applications. The compatibility of the injector fuel supply tube with these engines ensures that the fuel delivery system operates smoothly, reducing the risk of fuel leaks and maintaining consistent engine performance.

Group Compatibility

In addition to the QST30 CM552 engines, the Injector Fuel Supply Tube (3094872) is also compatible with a range of other Cummins engines. This part is engineered to meet the stringent requirements of Cummins’ fuel delivery systems, ensuring that it fits perfectly and functions efficiently across various engine models. The compatibility extends to engines that share similar design and operational characteristics, ensuring that the tube can be used across multiple platforms without compromising performance.

Role of Part 3094872 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 3094872, is an integral component within the fuel delivery system of various engine configurations. Its primary function is to transport pressurized fuel from the fuel rail to the fuel injectors. This ensures a consistent and regulated supply of fuel, which is essential for the injectors to atomize fuel effectively into the combustion chamber.

In conjunction with the fuel rail, the Injector Fuel Supply Tube maintains fuel pressure across all injectors, promoting uniform fuel distribution. This uniformity is vital for balanced cylinder performance and overall engine efficiency. The tube interfaces directly with the injectors, which are responsible for metering the precise amount of fuel required for combustion, based on engine load and operating conditions.

Furthermore, the Injector Fuel Supply Tube works in harmony with the fuel pump, which pressurizes the fuel, and the fuel filter, which ensures that any contaminants are removed before the fuel reaches the injectors. The consistent fuel pressure maintained by the tube is also influenced by the fuel pressure regulator, which modulates the pressure to meet the engine’s demands.

In high-performance engines, the Injector Fuel Supply Tube must be capable of handling increased fuel flow rates and higher pressures. This is to support the enhanced fuel delivery requirements of such engines, ensuring that they operate at peak performance levels without compromising reliability.

Overall, the Injector Fuel Supply Tube is a key element in the fuel system, facilitating the seamless operation of fuel injectors and contributing to the engine’s performance and efficiency.

Conclusion

The Injector Fuel Supply Tube (Part #3094872) is a vital component in the fuel system of heavy-duty trucks, ensuring efficient engine performance through consistent fuel delivery and optimal fuel pressure. Its durable construction, compatibility with various Cummins engines, and role in reducing emissions make it an essential part for maintaining engine efficiency and reliability.

-

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Cummins Corporation. Company history and product information. Retrieved from Cummins official website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.