This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

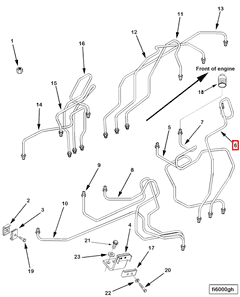

The Cummins Injector Fuel Supply Tube, part number 3093309, is a critical component designed for the efficient operation of heavy-duty trucks. This part ensures consistent and precise fuel delivery to the injectors, playing a vital role in the fuel system. Cummins, known for its high-quality diesel engines and components, offers this part as a reliable solution for truck operators and maintenance professionals.

Basic Concepts of Injector Fuel Supply Tube

The Injector Fuel Supply Tube operates on fundamental principles essential for the fuel system’s functionality. Its primary role is to transport fuel from the fuel rail to the injectors, maintaining proper fuel pressure and flow. The tube’s design and material are engineered to withstand the high pressures typical in modern diesel fuel systems, contributing to engine efficiency and performance 1.

Purpose of the Injector Fuel Supply Tube

The Injector Fuel Supply Tube serves a specific function within the truck’s fuel system by delivering fuel from the fuel rail to the injectors. This ensures a steady and precise fuel supply, directly impacting combustion quality, power output, and fuel consumption 2.

Key Features

The Injector Fuel Supply Tube, part number 3093309, features a durable construction designed to withstand high pressures and temperatures within the fuel system. Its precision engineering ensures a perfect fit and optimal performance within Cummins engines, tailored for high-pressure fuel systems 3.

Benefits

Utilizing the Injector Fuel Supply Tube offers several advantages, including improved fuel efficiency through precise fuel delivery, enhanced engine performance, and reduced risk of fuel leaks. Its robust construction ensures longevity under demanding operating conditions 4.

Installation and Compatibility

Proper installation of the Injector Fuel Supply Tube is crucial for optimal performance. It is designed to be compatible with various Cummins engine models, ensuring seamless integration into the fuel system. Following the manufacturer’s guidelines for installation is important to ensure correct fitting and operation 5.

Maintenance and Troubleshooting

Regular maintenance of the Injector Fuel Supply Tube is key to ensuring its longevity and performance. Inspections for wear, leaks, or blockages are recommended. Troubleshooting common issues may involve checking the tube’s fit within the system, inspecting for damage, and ensuring secure connections 6.

Safety Considerations

When working with the Injector Fuel Supply Tube, adhering to safety protocols is important. Handling fuel system components requires caution due to the high pressures and flammable nature of diesel fuel. Working in a well-ventilated area and wearing appropriate personal protective equipment is advisable 7.

Cummins Overview

Cummins Inc. is a leader in manufacturing diesel engines and components, known for quality and reliability. Its products, including the Injector Fuel Supply Tube, are designed with precision and durability, reflecting the company’s commitment to high-quality solutions for heavy-duty applications 8.

Compatibility with Cummins Engines

The Injector Fuel Supply Tube, part number 3093309, is compatible with various Cummins engines, including the QST30 CM552 engines. This compatibility ensures efficient and reliable fuel delivery, contributing to engine performance and longevity 9.

Role in Engine Systems

The Injector Fuel Supply Tube plays a crucial role in the fuel delivery system by transporting fuel from the fuel rail to the injectors. It ensures a consistent and regulated fuel supply, vital for the injectors to operate effectively and for optimal engine performance and fuel efficiency 10.

Conclusion

The Cummins Injector Fuel Supply Tube, part number 3093309, is a vital component in the fuel delivery system of heavy-duty trucks. Its role in ensuring consistent and precise fuel delivery to the injectors contributes to engine efficiency, performance, and safety. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this component.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Pacejka, Hans B. Tyre and Vehicle Dynamics. Butterworth-Heinemann, 2006.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Cummins Inc. Technical Documentation.

↩ -

Cummins Inc. Maintenance Guidelines.

↩ -

Occupational Safety and Health Administration (OSHA) Guidelines.

↩ -

Cummins Inc. Company Overview.

↩ -

Cummins Inc. Compatibility Information.

↩ -

Cummins Inc. Engine Systems Documentation.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.