This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

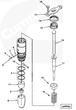

The Cummins 3084108 Injector is a critical component in the fuel system of commercial trucks, designed to deliver precise amounts of fuel into the engine’s combustion chambers. Its function is essential for maintaining engine performance, efficiency, and compliance with emissions standards in heavy-duty applications 3.

Basic Concepts of Fuel Injectors

Fuel injectors are integral to internal combustion engines, delivering fuel into the combustion chamber by atomizing it into a fine mist that mixes with air before ignition. This process enhances combustion efficiency, leading to improved engine performance and reduced emissions. The evolution of fuel injection technology has led to various types of injectors, each tailored to meet specific engine requirements and performance criteria 1.

Purpose of the Cummins 3084108 Injector

The Cummins 3084108 Injector is engineered to enhance the operation of commercial truck engines by ensuring precise fuel delivery. This precision contributes to optimal combustion, which is vital for maintaining power output, fuel economy, and emission levels within regulatory standards 3.

Key Features of the Cummins 3084108 Injector

This Cummins part is constructed using high-quality materials and incorporates technological advancements such as improved spray patterns and faster response times. These features contribute to better engine performance and efficiency, ensuring durability and precision in fuel delivery 1.

Benefits of Using the Cummins 3084108 Injector

Utilizing this part offers several advantages, including improved fuel efficiency through precise fuel delivery, enhanced engine performance via consistent and accurate fuel atomization, and reduced emissions, aligning with environmental regulations. It also increases the reliability of the engine system 3.

Installation and Compatibility

Proper installation of the Cummins 3084108 Injector is crucial for its optimal performance. It is designed to be compatible with a range of truck models and engine types, making it a versatile choice for fleet operators. Adhering to manufacturer guidelines during installation ensures correct function within the engine system 3.

Maintenance and Troubleshooting

Maintaining the Cummins 3084108 Injector is key to ensuring its longevity and performance. Regular maintenance includes cleaning and inspecting the injector for any signs of wear or damage. Troubleshooting common issues, such as poor fuel atomization or engine misfires, can often be resolved by cleaning or replacing the injector, ensuring efficient engine operation 3.

Performance Enhancements

The Cummins 3084108 Injector can contribute to performance enhancements in commercial trucks. By ensuring precise fuel delivery, it supports tuning options and aftermarket upgrades aimed at increasing engine power and efficiency. Its compatibility with various performance modifications makes it a valuable component for fleet operators looking to optimize their vehicles’ performance 1.

Environmental Impact

The use of the Cummins 3084108 Injector has positive environmental implications. By ensuring precise fuel delivery and efficient combustion, it helps reduce harmful emissions. Improved fuel efficiency also means lower fuel consumption, contributing to a smaller carbon footprint for commercial truck operations 2.

Cummins Corporation

Cummins Inc., the manufacturer of the 3084108 Injector, is renowned in the automotive industry for its innovation and commitment to quality. Their dedication to advancing technology is evident in the design and functionality of the Cummins 3084108 Injector 3.

Role of the 3084108 Injector in Engine Systems

The 3084108 injector is a pivotal component in the fuel delivery system of an engine, ensuring precise fuel atomization and distribution. It works in harmony with several key components to optimize engine performance and efficiency.

Fuel Rail Integration

The injector is mounted on the fuel rail, which distributes pressurized fuel to each cylinder. The fuel rail maintains consistent pressure, allowing the injector to deliver fuel with accuracy. This setup ensures that each cylinder receives the correct amount of fuel, promoting balanced combustion across the engine 3.

Engine Control Unit (ECU) Communication

The injector operates under the control of the ECU, which monitors various engine parameters such as throttle position, engine speed, and air-fuel ratio. The ECU sends signals to the injector to open and close at precise intervals, ensuring optimal fuel delivery for varying engine loads and conditions 3.

Throttle Body and Air Intake System

The injector’s performance is closely tied to the air intake system, particularly the throttle body. As the throttle body regulates the amount of air entering the engine, the injector adjusts fuel delivery to match the air volume. This synchronization is essential for maintaining the ideal air-fuel ratio, which is vital for efficient combustion and power output 1.

Combustion Chamber Dynamics

Once the fuel is injected into the combustion chamber, it interacts with the air and ignites, driving the piston downward. The injector’s role in delivering a fine mist of fuel enhances combustion efficiency, reducing emissions and improving overall engine performance 1.

Exhaust Gas Recirculation (EGR) System

The injector also plays a part in the EGR system by ensuring that the fuel-air mixture remains consistent even when recirculated exhaust gases are introduced. This helps in reducing nitrogen oxides (NOx) emissions while maintaining engine efficiency 2.

Oxygen Sensor Feedback

Oxygen sensors monitor the exhaust gases to provide feedback to the ECU about the air-fuel ratio. The injector adjusts its operation based on this feedback, ensuring that the engine runs as cleanly and efficiently as possible 3.

Conclusion

The Cummins 3084108 Injector is integral to the fuel delivery process, working in concert with the fuel rail, ECU, throttle body, air intake system, combustion chamber, EGR system, and oxygen sensors to ensure optimal engine performance and efficiency. Its role in enhancing combustion efficiency, reducing emissions, and improving fuel economy makes it a valuable component for commercial truck engines.

-

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010.

↩ ↩ ↩ ↩ ↩ -

Gas Turbine Engineering Handbook 4th Edition, Meherwan P Boyce, Butterworth-Heinemann, 2011.

↩ ↩ -

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.