This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

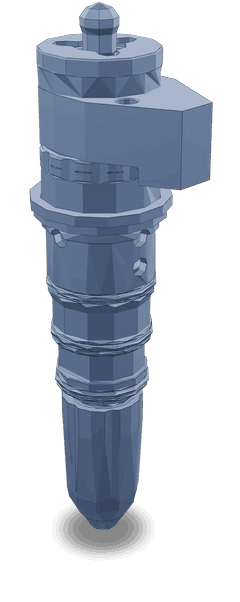

The Cummins 3075343 Injector is a component designed for use in commercial trucks, playing a significant role in their operation. This injector is part of the fuel delivery system, ensuring efficient and precise fuel injection into the engine cylinders. Its proper function is vital for maintaining the performance and efficiency of the truck’s engine 1.

Basic Concepts of Fuel Injectors

Fuel injectors are devices used in internal combustion engines to deliver fuel into the combustion chamber. They operate by atomizing fuel into a fine mist, which mixes with air before combustion. This process enhances fuel efficiency and reduces emissions 2. Fuel injectors are controlled electronically, allowing for precise timing and quantity of fuel delivery, which is crucial for engine performance and emissions control.

Purpose of the Cummins 3075343 Injector

The Cummins 3075343 Injector serves a specific role in the operation of a truck by facilitating the delivery of fuel into the engine’s combustion chambers. It ensures that fuel is injected at the correct pressure and timing, which is essential for optimal engine performance. This injector is part of the high-pressure common rail fuel system, which allows for more precise control over fuel delivery compared to traditional fuel systems 3.

Key Features

The Cummins 3075343 Injector is characterized by several key features. Its design incorporates advanced technology to ensure precise fuel delivery. The injector is constructed from durable materials to withstand the high pressures and temperatures within the engine. It also features sophisticated electronics for accurate fuel metering and timing. Additionally, the injector is designed for easy installation and integration into the truck’s fuel system.

Benefits

The Cummins 3075343 Injector offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered in the most efficient manner possible. This results in better overall performance of the truck, with increased power output and smoother operation. Additionally, the injector helps in reducing emissions, making the truck more environmentally friendly. Its reliable design ensures consistent performance over time.

Installation and Integration

Proper installation of the Cummins 3075343 Injector is crucial for its effective operation. The installation process involves ensuring that the injector is correctly aligned and secured within the fuel rail. It is also important to verify that the electrical connections are properly made to ensure the injector receives the correct signals for operation. Careful attention to these details during installation helps in achieving optimal performance from the injector.

Performance Impact

The Cummins 3075343 Injector has a noticeable impact on the overall performance of the truck. By providing precise fuel delivery, it contributes to increased power output and improved fuel efficiency. The injector also plays a role in reducing emissions, making the truck more compliant with environmental regulations. Its integration into the fuel system enhances the engine’s responsiveness and overall driving experience.

Common Issues and Troubleshooting

Like any mechanical component, the Cummins 3075343 Injector may encounter issues over time. Common problems include clogging due to fuel contaminants, electrical faults affecting the injector’s operation, and mechanical wear. Troubleshooting these issues involves inspecting the injector for signs of wear or damage, checking electrical connections, and ensuring the fuel system is clean and free of contaminants. Regular maintenance can help in identifying and addressing these issues before they lead to significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3075343 Injector, regular maintenance is recommended. This includes periodic inspection of the injector for signs of wear or damage, cleaning the injector and fuel system to prevent clogging, and checking electrical connections for corrosion or loose fittings. Adhering to these maintenance practices helps in maintaining the injector’s efficiency and reliability.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its high-quality engines and components. With a history spanning several decades, Cummins has built a reputation for innovation, reliability, and performance. The company’s commitment to excellence is reflected in its wide range of products, including the Cummins 3075343 Injector, which is designed to meet the demanding requirements of commercial truck applications.

Role of Part 3075343 Injector in Performance Engine Systems

The part 3075343 injector is a specialized component designed to enhance the fuel delivery process in performance engine systems. Its primary function is to atomize fuel into a fine mist, ensuring optimal combustion efficiency. This injector works in conjunction with several key components to achieve peak performance.

Integration with Fuel Rail and Injector Harness

The injector is mounted on the fuel rail, a component that distributes pressurized fuel to each cylinder. The injector harness, which connects the injector to the engine’s electronic control unit (ECU), plays a vital role in regulating the fuel delivery based on engine load and RPM. The precise control offered by the harness ensures that the injector delivers the exact amount of fuel required for optimal performance.

Interaction with Engine Control Unit (ECU)

The ECU monitors various engine parameters such as air-fuel ratio, engine temperature, and throttle position. It sends signals to the injector to open and close at specific intervals, ensuring that fuel is delivered in a manner that maximizes power output and efficiency. The injector’s ability to respond quickly to these signals is essential for maintaining the desired air-fuel ratio under varying driving conditions.

Coordination with Turbocharger and Intercooler

In turbocharged engines, the injector must work in harmony with the turbocharger and intercooler. The turbocharger increases the air density entering the engine, requiring a corresponding increase in fuel delivery to maintain the correct air-fuel ratio. The intercooler reduces the temperature of the compressed air, which increases its density and allows for more fuel to be burned efficiently. The injector must be capable of delivering the increased fuel volume without causing enrichment or detonation.

Synergy with Performance Air Intake and Exhaust Systems

A performance air intake system provides a more unrestricted airflow into the engine, demanding a higher fuel flow to match the increased air volume. Similarly, a high-flow exhaust system reduces backpressure, allowing the engine to breathe more freely and requiring the injector to deliver fuel in a manner that supports the enhanced exhaust flow. The injector’s precise fuel delivery ensures that the engine operates efficiently across a broader range of RPMs.

Compatibility with Nitrous Oxide Systems

In engines equipped with nitrous oxide systems, the injector plays a pivotal role in delivering the additional fuel required to support the increased oxygen provided by the nitrous. The injector must be capable of handling the sudden increase in fuel demand without causing over-rich conditions, which could lead to engine damage.

Enhanced Performance with Aftermarket ECUs

Aftermarket ECUs offer advanced tuning capabilities that allow for more precise control over fuel delivery. When paired with the 3075343 injector, these ECUs can fine-tune the fuel maps to extract maximum performance from the engine. The injector’s high-flow rate and quick response time make it an ideal match for engines running on aftermarket ECUs.

Conclusion

In summary, the Cummins 3075343 Injector is a vital component in performance engine systems, working in concert with various other components to ensure optimal fuel delivery and combustion efficiency. Its ability to adapt to different engine configurations and tuning scenarios makes it a valuable asset in any high-performance application.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.