This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

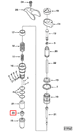

The Cummins Injector Cup, part number 3073575, is a critical component in the operation of heavy-duty truck engines. Cummins, a leading name in the diesel engine industry, manufactures this part to enhance the efficiency and reliability of their engine systems. Understanding the role and functionality of this Cummins part is essential for maintaining and optimizing the performance of Cummins-powered trucks.

Basic Concepts and Functionality

Injector cups are fundamental components in diesel engine fuel injection systems. They serve as the interface between the fuel injector and the engine cylinder, maintaining fuel pressure and ensuring a proper seal. The Injector Cup 3073575 operates within Cummins engines by providing a secure fitting for the injector, which is crucial for the precise delivery of fuel into the combustion chamber. This part helps withstand the high pressures and temperatures present in diesel engines, ensuring that fuel is delivered efficiently and effectively 1.

Purpose of Injector Cup 3073575

The Injector Cup 3073575 plays a role in several key functions within a truck’s engine system. It maintains fuel pressure by creating a seal that prevents fuel leakage, which is vital for the consistent operation of the fuel injection system. Additionally, it ensures that the injector is securely held in place, which is important for the accurate delivery of fuel. Efficient fuel delivery is crucial for optimal engine performance, making the injector cup a significant component in the overall operation of the engine 2.

Key Features

The Injector Cup 3073575 is designed with several features that enhance its performance and durability. It is typically made from high-quality materials that can withstand the extreme conditions within a diesel engine. The design includes elements that improve its sealing capabilities and resistance to wear and corrosion. These features contribute to the overall reliability and longevity of the part, differentiating it from other injector cups on the market 3.

Benefits

The advantages provided by the Injector Cup 3073575 include improved engine efficiency through reliable fuel delivery and pressure maintenance. Its design reduces the risk of fuel leaks, which can lead to engine performance issues and potential safety hazards. Enhanced durability ensures that the part can withstand the demanding conditions of heavy-duty truck operations, contributing to the overall performance and longevity of the engine.

Installation and Maintenance

Proper installation of the Injector Cup 3073575 is important for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and proper sealing. Regular maintenance practices, such as inspecting for signs of wear or damage and ensuring that all connections are tight, can help in maintaining the part’s performance. Addressing common issues promptly, such as leaks or performance declines, can prevent more significant problems down the line.

Troubleshooting

Diagnosing common problems associated with injector cups, such as leaks or performance issues, involves a systematic approach. Inspecting the cup for signs of wear, corrosion, or damage is a good starting point. If issues are detected, following the manufacturer’s recommended remedies or considering replacement may be necessary to restore proper function. Regular maintenance and timely replacements can help in preventing issues from escalating.

Manufacturer - Cummins

Cummins Inc. is a renowned manufacturer in the diesel engine industry, known for its high-quality automotive components. With a history of innovation and commitment to excellence, Cummins has established a reputation for producing reliable and durable engine parts. The company’s dedication to quality and performance is evident in its product line, including the Injector Cup 3073575, which is designed to meet the rigorous demands of heavy-duty truck engines.

Cummins Injector Cup (Part 3073575) Compatibility

The Cummins Injector Cup, identified by part number 3073575, is a critical component in the fuel injection system of various Cummins engines. This part is designed to fit seamlessly within the engine architecture, ensuring optimal fuel delivery and combustion efficiency.

N14 Mechanical Engine

The N14 Mechanical engine, a robust and reliable power unit, is one of the engines that can utilize the Injector Cup 3073575. This engine is known for its durability and performance, making it a popular choice in various applications, including heavy-duty trucks and industrial machinery. The injector cup plays a vital role in maintaining the engine’s efficiency by ensuring precise fuel atomization and delivery.

The injector cup’s design is tailored to fit the specific requirements of the N14 engine, ensuring a secure and leak-free connection. This compatibility is crucial for maintaining the engine’s performance and longevity. The injector cup’s material and construction are engineered to withstand the high pressures and temperatures encountered in the engine’s combustion chamber, providing a reliable and durable solution for fuel injection.

Role of Part 3073575 Injector Cup in Engine Systems

The injector cup, identified by part number 3073575, is an integral component in the fuel injection system of an engine. Its primary function is to provide a secure and sealed environment for the injector within the cylinder head. This ensures that the fuel is delivered precisely and efficiently into the combustion chamber.

Interaction with the Injector

The injector cup interfaces directly with the fuel injector, supporting it within the cylinder head. This interaction is vital for maintaining the integrity of the fuel injection process. The cup must withstand high pressures and temperatures, ensuring that the injector operates within specified parameters.

Support for Combustion Efficiency

By providing a robust mounting point for the injector, the 3073575 injector cup contributes to the overall efficiency of the combustion process. It helps in maintaining the correct fuel spray pattern, which is essential for optimal air-fuel mixture and combustion efficiency.

Thermal Management

The injector cup also plays a role in thermal management within the cylinder head. It helps in dissipating heat away from the injector, preventing overheating and potential damage to the injector and surrounding components.

Seal Integrity

Ensuring a tight seal between the injector and the cylinder head is another significant role of the injector cup. This seal prevents fuel leakage, which could lead to inefficient combustion and potential engine damage. The cup must be designed to withstand the cyclic loading and thermal stresses encountered during engine operation.

Contribution to Engine Longevity

By providing a stable and secure environment for the injector, the injector cup contributes to the longevity and reliability of the engine. It reduces the likelihood of injector failure and associated engine issues, thereby enhancing overall engine performance and durability.

Conclusion

The Cummins Injector Cup, part number 3073575, is a vital component in the fuel injection system of heavy-duty truck engines. Its role in maintaining fuel pressure, ensuring a secure fit for the injector, and contributing to combustion efficiency and engine longevity cannot be overstated. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the performance and reliability of this part. Cummins’ commitment to quality and innovation is reflected in the design and functionality of the Injector Cup 3073575, making it a cornerstone of their engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.