This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

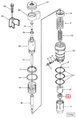

The Cummins Injector Cup, identified by part number 3071564, is a critical component in the fuel injection system of heavy-duty trucks. It ensures the proper functioning of the fuel injector by maintaining the integrity of the fuel system and facilitating efficient fuel delivery. Understanding the function and significance of the injector cup is essential for maintaining engine performance and reliability in demanding operational environments.

Basic Concepts of Injector Cups

An injector cup is a cylindrical component that houses the fuel injector within the engine cylinder. It serves as a seal between the injector and the cylinder, preventing fuel leakage and ensuring that fuel is delivered precisely when needed. The injector cup contributes to the overall performance of the engine by maintaining consistent fuel pressure and protecting the injector from cylinder pressure and heat 1.

Purpose of the Injector Cup

This Cummins part plays a role in the operation of a truck by securing the fuel injector in place and providing a seal that prevents fuel from leaking into the cylinder. It ensures that fuel is delivered at the correct pressure and timing, which is crucial for efficient combustion and engine performance. Additionally, the injector cup helps to maintain the integrity of the fuel system by withstanding high pressures and temperatures 2.

Key Features of the Injector Cup

The Injector Cup is designed with several features that enhance its performance and durability. It is constructed from high-strength materials that can withstand the extreme conditions within the engine cylinder. The cup includes a precision-machined surface to ensure a tight seal with the injector and cylinder. Additionally, it may feature unique attributes such as heat-resistant coatings or reinforced structures to improve longevity and reliability.

Benefits of Using the Injector Cup

Utilizing this Cummins part offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered precisely when needed, reducing waste and enhancing combustion efficiency. The cup also enhances engine performance by maintaining consistent fuel pressure and timing. Furthermore, its robust construction increases reliability, particularly in demanding operating conditions, leading to reduced maintenance requirements and extended engine life.

Installation and Maintenance

Proper installation of the Injector Cup is crucial for ensuring optimal performance and longevity. It should be installed according to manufacturer specifications, which may include torque settings and recommended procedures to avoid damage. Regular maintenance, such as inspecting for wear and ensuring proper sealing, is important to prevent issues such as fuel leaks or performance degradation. Following these guidelines helps to maintain the integrity of the fuel system and ensures reliable engine operation.

Troubleshooting Common Issues

Common problems associated with injector cups include leaks and performance issues. These can often be traced to improper installation, wear, or damage to the cup. Troubleshooting steps may involve inspecting the cup for signs of wear or damage, ensuring that it is properly seated and sealed, and verifying that installation torque specifications were followed. Addressing these issues promptly can help to maintain engine performance and prevent more serious problems.

Manufacturer Information - Cummins

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its high-quality engine components. With a history of innovation and commitment to excellence, Cummins has built a reputation for producing reliable and durable parts. The company’s focus on quality and performance ensures that components like the Injector Cup meet the rigorous demands of heavy-duty applications.

Understanding the Role of Part 3071564 Injector Cup in Engine Systems

The injector cup, specifically part 3071564, is an integral component within the fuel injection system of an engine. Its primary function is to provide a secure and sealed environment for the injector to operate within the cylinder head. This ensures that fuel is delivered precisely and efficiently to the combustion chamber.

Interaction with the Injector

The injector cup houses the fuel injector, allowing it to penetrate the cylinder head without compromising the integrity of the fuel system. The cup’s design facilitates the injector’s movement, which is essential for the fuel injection process. It also helps in managing the high pressures and temperatures that the injector experiences during operation.

Contribution to Parts Longevity

By providing a robust interface between the injector and the cylinder head, the injector cup plays a significant role in the longevity of engine parts. It helps in distributing the stresses exerted on the injector, thereby reducing the likelihood of part failure. This is particularly important in high-performance engines where the components are subjected to extreme conditions.

Enhancing Engine Performance

The precise fit and sealing properties of the injector cup are vital for maintaining engine performance. It ensures that fuel is delivered consistently and without leaks, which is essential for optimal combustion. This, in turn, contributes to better fuel efficiency, reduced emissions, and overall enhanced engine performance.

Supporting System Integrity

The injector cup also supports the integrity of the entire fuel injection system. By ensuring a secure fit and proper sealing, it prevents fuel from leaking into the cylinder head or other areas, which could lead to system malfunctions. This is particularly important in maintaining the reliability and safety of the engine.

Conclusion

In summary, part 3071564 injector cup is a key component that supports the efficient and reliable operation of the fuel injection system. Its role in securing the injector, contributing to parts longevity, enhancing engine performance, and supporting system integrity cannot be overstated.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.