This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

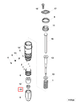

The Cummins Injector Cup Part #3071046 is a component designed for use in heavy-duty trucks. It plays a significant role in the fuel injection system, contributing to the overall efficiency and performance of the vehicle. Understanding its purpose and functionality is key to maintaining the optimal operation of heavy-duty trucks.

Basic Concepts of Injector Cups

An injector cup is a component within the fuel injection system of diesel engines. It houses the fuel injector and seals the injector to the cylinder head. The injector cup ensures that fuel is delivered precisely and efficiently to the combustion chamber, interacting closely with the fuel injector and cylinder head to maintain system integrity 1.

Purpose of the 3071046 Injector Cup

The 3071046 Injector Cup maintains the integrity of the fuel system and ensures proper fuel delivery. It provides a secure seal for the fuel injector, preventing leaks and maintaining the necessary pressure for efficient fuel injection. This component is integral to the consistent performance and reliability of the engine 2.

Key Features

The 3071046 Injector Cup is characterized by several key features that enhance its performance. It is made from durable materials that can withstand the high pressures and temperatures within the engine. The design includes precise machining to ensure a tight seal and compatibility with the fuel injector and cylinder head. Additionally, it may feature unique characteristics such as improved heat dissipation properties to enhance longevity and performance 3.

Benefits of Using the 3071046 Injector Cup

Utilizing the 3071046 Injector Cup offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered accurately and under the correct pressure. This component also enhances engine performance by maintaining consistent fuel injection, which is critical for power output and engine responsiveness. Furthermore, its durable construction increases the overall longevity of the fuel injection system.

Installation Process

Installing the 3071046 Injector Cup requires careful attention to detail to ensure proper function and longevity. The process involves removing the old injector cup, cleaning the cylinder head surface, and then installing the new cup with the fuel injector. It is important to follow manufacturer guidelines for torque specifications and to use the appropriate tools to avoid damage. Best practices include inspecting the O-rings and gaskets for wear and replacing them if necessary to maintain a secure seal.

Common Issues and Troubleshooting

Injector cups can encounter issues such as leaks or failures, which may lead to decreased engine performance or fuel efficiency. Common problems include worn O-rings, gasket failures, or cracks in the cup itself. Troubleshooting these issues involves inspecting the injector cup and related components for signs of wear or damage. Replacing worn parts and ensuring proper installation can resolve most issues.

Maintenance Tips

To ensure the longevity and optimal performance of the 3071046 Injector Cup, regular maintenance is recommended. This includes periodic inspection of the injector cup and related components for signs of wear or damage. Cleaning the injector cup and cylinder head surface during maintenance intervals can prevent buildup that may affect performance. Additionally, following the manufacturer’s guidelines for replacement intervals can help maintain the integrity of the fuel injection system.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, particularly known for its diesel engines and components. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance engine parts. The company’s commitment to excellence is reflected in its wide range of products, including the 3071046 Injector Cup, which is designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3071046 Injector Cup in Engine Systems

Part 3071046 Injector Cup is an essential component in the fuel injection system of an engine. It is specifically designed to work in conjunction with the injector to ensure optimal performance and efficiency.

Interaction with Injector

The Injector Cup, part 3071046, serves as a seal and support structure for the injector within the cylinder head. It creates a secure environment for the injector tip, allowing it to deliver fuel into the combustion chamber with precision. This interaction is vital for maintaining the integrity of the fuel spray pattern and ensuring that the fuel is atomized correctly for efficient combustion.

Contribution to Performance Parts

Incorporating part 3071046 into performance-oriented engine systems enhances the overall efficiency and reliability of the fuel injection process. By providing a robust and precise seating for the injector, this component helps in achieving consistent fuel delivery, which is a key factor in maximizing engine performance.

Enhanced Fuel Atomization

The design of the Injector Cup allows for improved fuel atomization, which is essential for complete combustion. Finely atomized fuel mixes more effectively with air, leading to a more powerful and cleaner burn. This not only boosts engine power but also reduces emissions, making the engine more environmentally friendly.

Durability and Reliability

Part 3071046 is engineered to withstand the high pressures and temperatures within the engine. Its durable construction ensures long-term reliability, reducing the need for frequent replacements and maintenance. This durability is particularly important in high-performance engines where the demands on components are greater.

Support for High-Pressure Fuel Systems

In modern engines with high-pressure fuel systems, the Injector Cup plays a significant role in maintaining the integrity of the fuel delivery system. It helps in managing the high pressures that are characteristic of these systems, ensuring that the fuel is delivered consistently and efficiently.

Integration with Cylinder Head

The Injector Cup is an integral part of the cylinder head assembly. It fits precisely within the cylinder head, providing a secure and leak-free connection for the injector. This integration is essential for maintaining the overall structural integrity of the engine and ensuring that the fuel injection system operates within specified parameters.

Conclusion

In summary, part 3071046 Injector Cup is a key component that enhances the functionality and performance of the fuel injection system in engine applications. Its role in supporting the injector, ensuring precise fuel delivery, and contributing to overall engine efficiency makes it an indispensable part of modern engine designs.

-

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics (Springer Nature, 2023).

↩ -

Hua Zhao, Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines (CRC Press, 2010).

↩ -

Willard W. Pulkrabek, Engineering Fundamentals of the Internal Combustion Engine (Pearson Education, 2014).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.