This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Cup (Part #3068895) is a component designed to facilitate the operation of fuel injectors in heavy-duty trucks. Its role is significant in maintaining the integrity and efficiency of the fuel injection system. This part ensures that fuel is delivered precisely and effectively to the engine’s combustion chambers, contributing to overall engine performance 1.

Basic Concepts and Functionality

Injector cups are integral to the fuel injection system, serving as a seal between the injector and the cylinder head. They play a role in maintaining the pressure and integrity of the fuel as it is delivered to the combustion chamber. Proper functionality of the injector cup ensures that fuel is atomized correctly, which is vital for efficient combustion and engine performance 2.

Purpose and Role in Truck Operation

This Cummins part is specifically designed to enhance the performance and efficiency of the truck’s engine. By providing a secure and reliable seal, it helps maintain the high pressures required for fuel injection. This ensures that fuel is delivered consistently and efficiently, which contributes to the engine’s overall performance, power output, and fuel economy.

Key Features

The Injector Cup is crafted with precision to meet the demanding requirements of heavy-duty truck engines. It is made from durable materials that can withstand high pressures and temperatures. The design includes features that enhance its sealing capabilities, ensuring that fuel delivery is precise and reliable. Additionally, the cup is engineered to be compatible with Cummins fuel injectors, ensuring seamless integration into the engine system 3.

Benefits

Using this part offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered accurately and under the correct pressure. This results in more complete combustion, which enhances engine performance. Additionally, the robust design of the injector cup increases its durability and reliability, reducing the likelihood of failures and the need for frequent replacements.

Troubleshooting and Maintenance

Common issues with injector cups may include cracking, leakage, or wear. Regular inspection and maintenance can help identify these problems early. Techniques such as visual inspection, pressure testing, and analysis of engine performance data can be employed to diagnose issues. Proper maintenance practices, including regular cleaning and inspection, can ensure optimal performance and longevity of the injector cup.

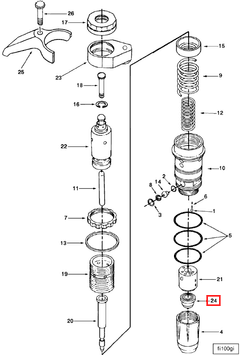

Installation Procedures

Installing 3068895 requires careful attention to detail. The process involves removing the old cup, cleaning the cylinder head surface, and installing the new cup with the correct torque specifications. Special considerations include ensuring that the cup is properly seated and that all seals are intact to prevent leaks. Following the manufacturer’s guidelines is important to ensure a successful installation.

Common Failure Modes

Injector cups can fail due to various reasons, including cracking, leakage, or wear. These failures can impact engine performance by causing issues such as poor fuel efficiency, reduced power output, or even engine misfires. Understanding these failure modes can help in diagnosing problems and taking corrective action.

Diagnostic Techniques

To identify issues with injector cups, several diagnostic techniques can be used. Visual inspection can reveal cracks or damage. Pressure testing can help determine if there are leaks in the fuel system. Analyzing engine performance data, such as fuel consumption and power output, can also provide insights into the condition of the injector cups.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality products and innovative solutions. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry. The company offers a wide range of products, including engines, filtration systems, and power generation equipment, catering to various industries and applications.

Role of Part 3068895 Injector Cup in Engine Systems

The injector cup, specifically part 3068895, is an integral component within the fuel injection system of an engine. Its primary function is to provide a secure and sealed environment for the injector within the cylinder head. This ensures that fuel is delivered precisely and efficiently to the combustion chamber.

Interaction with Injectors

This part directly interfaces with the fuel injector. It houses the injector tip, maintaining the integrity of the fuel path from the injector to the combustion chamber. This interaction is vital for the accurate delivery of fuel, which directly influences engine performance and efficiency.

Contribution to Performance Parts

In the context of performance parts, the injector cup plays a significant role. High-performance engines often require modifications to the fuel system to handle increased fuel demands. The injector cup must be capable of withstanding higher pressures and temperatures associated with performance enhancements. It ensures that the injector operates within optimal conditions, contributing to the overall performance gains of the engine.

Sealing and Containment

One of the key functions of the injector cup is to create a robust seal around the injector. This seal prevents fuel leakage into the cylinder head, which could lead to a host of issues including reduced performance and potential engine damage. The cup must be durable enough to maintain this seal under varying operating conditions.

Thermal Management

The injector cup also aids in thermal management within the cylinder head. It helps to dissipate heat generated by the injector and the combustion process, protecting surrounding components from excessive temperatures. Effective thermal management is essential for the longevity and reliability of the engine.

Support for Fuel System Integrity

By ensuring a secure fit and proper sealing, the injector cup supports the overall integrity of the fuel system. It allows for consistent fuel delivery, which is paramount for engine performance. Any compromise in the injector cup’s functionality can lead to inefficiencies in fuel delivery, affecting engine operation.

Conclusion

In summary, part 3068895 Injector Cup is a fundamental component that ensures the reliable and efficient operation of the fuel injection system. Its role in sealing, thermal management, and supporting performance enhancements underscores its importance in modern engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.