Introduction

The Injector Plunger Link, identified by part number 3062674, is a component manufactured by Cummins, a leader in diesel engine technology. This part is integral to the operation of diesel engines, facilitating efficient fuel injection. Cummins, known for its commitment to innovation and quality, produces this component to ensure reliable and optimal performance in diesel engines 1.

Function and Operation

The Injector Plunger Link operates within the fuel injection system of a diesel engine. It connects the injector plunger to the camshaft, allowing for precise timing of fuel injection. As the camshaft rotates, it actuates the plunger link, which in turn moves the injector plunger. This movement results in the injection of fuel into the combustion chamber at the correct moment, ensuring efficient combustion and engine performance. The link’s design allows for smooth and consistent operation, minimizing wear and ensuring longevity 2.

Purpose of the Injector Plunger Link

The Injector Plunger Link plays a role in the operation of a truck by contributing to the fuel delivery system. It ensures that fuel is injected into the engine’s cylinders at the optimal time, which is crucial for maintaining engine efficiency and performance. By facilitating precise fuel injection, the link helps in achieving better fuel economy, reduced emissions, and overall engine reliability 3.

Key Features

The Injector Plunger Link is designed with several key features that enhance its functionality. It is constructed from durable materials to withstand the high pressures and temperatures within the engine. The design includes precise tolerances to ensure smooth operation and minimal friction. Additionally, the link may feature anti-wear coatings or treatments to extend its service life and maintain performance over time 4.

Benefits

The advantages provided by the Injector Plunger Link include improved fuel efficiency, enhanced engine performance, and increased reliability. By ensuring precise fuel injection timing, the link contributes to more complete combustion, which can lead to better fuel economy. It also plays a role in maintaining consistent engine performance under varying load conditions. Furthermore, the robust design and quality materials used in its construction contribute to the overall reliability of the fuel injection system.

Installation and Compatibility

Proper installation of the Injector Plunger Link is important for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, which may include specific torque settings and alignment procedures. Compatibility with various engine models should be verified to ensure the link fits correctly and functions as intended within the fuel injection system.

Maintenance and Troubleshooting

To ensure the Injector Plunger Link operates efficiently, regular maintenance is recommended. This may include inspecting the link for signs of wear or damage, ensuring it moves freely without obstruction, and checking for proper alignment. Common issues that may arise include wear on the link or misalignment, which can affect fuel injection timing. Troubleshooting steps may involve cleaning or replacing the link if necessary, following the manufacturer’s recommendations for maintenance and repair.

Safety Considerations

When working with the Injector Plunger Link, it is important to observe safety guidelines and precautions. This includes ensuring the engine is off and cool before beginning any work, using appropriate personal protective equipment, and following all manufacturer instructions for installation, maintenance, and repair. Additionally, care should be taken to avoid contact with high-pressure fuel systems to prevent injury.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a pioneer in diesel engine technology, committed to innovation, quality, and customer satisfaction. The company’s expertise in engine manufacturing is evident in its wide range of products, designed to meet the demanding requirements of various industries, including transportation, construction, and power generation.

Injector Plunger Link (Part 3062674) in Cummins Engines

The injector plunger link, identified by the part number 3062674 and manufactured by Cummins, plays a crucial role in the operation of the fuel injection system in certain Cummins engines. This component is integral to the precise delivery of fuel to the combustion chamber, ensuring optimal engine performance and efficiency.

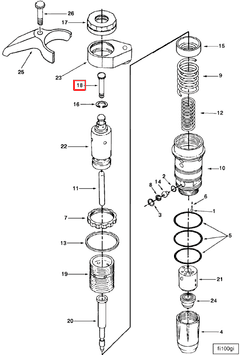

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the injector plunger link is a vital part of the injector assembly. It connects the injector plunger to the injector body, facilitating the movement necessary for opening and closing the fuel injector nozzle. This movement is essential for controlling the timing and quantity of fuel injected into the engine cylinders. The precision and durability of the injector plunger link are critical to maintaining the high standards of performance expected from Cummins engines.

The injector plunger link must withstand the high pressures and temperatures within the engine, ensuring reliable operation over extended periods. Its design and material composition are optimized to endure the rigors of continuous use, contributing to the overall longevity and reliability of the engine’s fuel injection system.

Understanding the Role of Part 3062674 Injector Plunger Link in Engine Systems

The Injector Plunger Link, identified by part number 3062674, is a key component in the orchestration of fuel injection within engine systems. This component is integral to the functionality of the injector, ensuring precise and efficient fuel delivery.

When considering the injector’s operation, the Injector Plunger Link works in concert with the injector to control the amount of fuel that is released into the combustion chamber. This is achieved through a mechanical linkage that translates the movement of the injector into the precise motion required to open and close the fuel delivery valve.

In the context of EBM (Engine Building and Modification) performance parts, the Injector Plunger Link is often a focus for enhancement. Upgrading this component can lead to improvements in fuel atomization and combustion efficiency, directly impacting the overall performance of the engine.

Moreover, within the realm of EBM performance parts, the Injector Plunger Link is frequently modified or replaced to accommodate higher fuel flow rates or to fine-tune the injection timing. This is particularly relevant in high-performance applications where every millisecond and every drop of fuel can make a significant difference in engine output and efficiency.

The integration of the Injector Plunger Link with other performance parts is also noteworthy. For instance, when paired with high-flow injectors, the link must be capable of handling the increased fuel volume without compromising the precision of the injection event. Similarly, when used in conjunction with advanced engine management systems, the Injector Plunger Link must be reliable and consistent to ensure that the engine’s electronic control unit (ECU) can accurately modulate fuel delivery.

Conclusion

The Injector Plunger Link (part 3062674) is a fundamental element in the fuel injection process, playing a significant role in the performance and efficiency of engine systems. Its interaction with injectors and other performance parts underscores its importance in the pursuit of enhanced engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.