This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

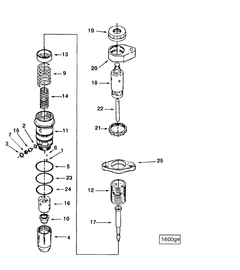

Introduction

The Cummins 3058802 Injector is a component designed for use in commercial trucks powered by Cummins engines. It plays a significant role in the fuel delivery system, ensuring efficient combustion and optimal engine performance. Understanding its function and significance is essential for maintaining and enhancing the operation of these vehicles.

Basic Concepts of Fuel Injectors

Fuel injectors are components within an engine’s fuel delivery system responsible for spraying fuel into the combustion chamber at precise moments and in specific quantities. They ensure that the air-fuel mixture is optimal for combustion, which directly affects engine performance, fuel efficiency, and emissions 1. The efficiency of fuel injectors is crucial for the overall operation of the engine, as they contribute to the power output and the smoothness of engine operation.

Purpose of the Cummins 3058802 Injector

The Cummins 3058802 Injector is designed to deliver fuel into the engine’s combustion chamber with precision. It plays a role in the fuel delivery system by atomizing fuel into fine particles, which enhances combustion efficiency. This efficient combustion leads to better engine performance, improved fuel economy, and reduced emissions 2. The injector’s ability to deliver fuel at the right time and in the correct amount is fundamental to the engine’s operation and efficiency.

Key Features

The Cummins 3058802 Injector incorporates several key features that enhance its performance. Its design includes advanced nozzle technology that ensures precise fuel atomization. The materials used in its construction are selected for durability and resistance to the high pressures and temperatures within the engine. Technological advancements such as electronic control and feedback mechanisms allow for fine-tuning of fuel delivery, contributing to its efficiency and reliability 3.

Benefits

Utilizing the Cummins 3058802 Injector offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is used more effectively during combustion. This injector also enhances engine performance by providing a consistent and precise fuel delivery, which is crucial for maintaining engine power and responsiveness. Additionally, its design helps in reducing emissions, making it compliant with environmental regulations and contributing to a lower environmental impact.

Installation and Compatibility

Proper installation of the Cummins 3058802 Injector is crucial for its performance and the overall health of the engine. It is designed to be compatible with specific Cummins engine models, ensuring that it fits seamlessly into the engine’s fuel delivery system. Following manufacturer guidelines for installation is important to ensure that the injector operates as intended and to avoid potential issues with engine performance.

Maintenance and Troubleshooting

Maintaining the Cummins 3058802 Injector is important for its longevity and performance. Regular checks and cleaning can prevent buildup and ensure that the injector continues to deliver fuel efficiently. Common issues may include clogging or wear, which can affect fuel delivery. Troubleshooting these issues often involves cleaning the injector or, in some cases, replacing it to restore optimal engine performance.

Performance Enhancements

The Cummins 3058802 Injector contributes to overall engine performance by ensuring that fuel is delivered efficiently and effectively. This leads to improvements in power output and fuel economy. Its precise fuel delivery helps in achieving a more complete combustion, which is beneficial for both performance and emissions.

Environmental Impact

The use of the Cummins 3058802 Injector has a positive environmental impact. By ensuring efficient fuel combustion, it helps in reducing emissions from the engine. This not only contributes to compliance with environmental regulations but also reduces the overall carbon footprint of the vehicle.

Cummins Corporation

Cummins Inc. is a leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient engine components. Their focus on advancing technology and meeting the needs of their customers underscores their position in the industry.

Compatibility with Cummins Engines

The Cummins injector part 3058802 is designed to ensure efficient fuel delivery in diesel engines. This part is engineered to fit seamlessly within specific engine models, enhancing performance and reliability.

K38 and K50 Engines

The injector part 3058802 is compatible with both the K38 and K50 engines. These engines are known for their robust design and are often utilized in heavy-duty applications, where reliability and efficiency are paramount.

-

K38 Engine: The injector part 3058802 is specifically designed to integrate with the K38 engine, ensuring precise fuel injection. This compatibility is crucial for maintaining the engine’s performance and longevity.

-

K50 Engine: Similarly, the injector part 3058802 fits perfectly with the K50 engine. This engine model benefits from the precise fuel delivery provided by this injector, ensuring optimal combustion and efficiency.

Installation and Performance

When installing the Cummins injector part 3058802 in either the K38 or K50 engines, it is essential to follow the manufacturer’s guidelines to ensure proper fit and function. This injector is designed to withstand the high pressures and temperatures associated with diesel engines, providing a reliable and consistent fuel delivery system.

Maintenance and Reliability

Regular maintenance of the injector part 3058802 is crucial to ensure its longevity and performance. This includes periodic inspections for wear and tear, as well as cleaning to prevent buildup that could affect fuel delivery. By maintaining this injector, users can ensure that their K38 and K50 engines continue to operate at peak efficiency.

Role of Part 3058802 Injector in Engine Systems

The 3058802 Injector is a significant component in the fuel delivery system of various engine setups. Its primary function is to precisely deliver fuel into the combustion chamber, ensuring optimal fuel-air mixture for efficient combustion.

Interaction with Fuel Rail

The injector is mounted on the fuel rail, a component that distributes pressurized fuel to each injector. The fuel rail maintains consistent pressure across all injectors, ensuring uniform fuel delivery. The 3058802 Injector, when activated by the Engine Control Unit (ECU), sprays fuel into the intake port or directly into the combustion chamber, depending on the engine design.

Coordination with Engine Control Unit (ECU)

The ECU plays a pivotal role in the operation of the 3058802 Injector. It monitors various sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor to determine the appropriate fuel delivery rate. The ECU sends signals to the injector to open and close at specific intervals, regulating the amount of fuel injected based on real-time data.

Synergy with Intake Manifold

The intake manifold is responsible for distributing the air-fuel mixture to each cylinder. The 3058802 Injector works in conjunction with the intake manifold to ensure that each cylinder receives a consistent and precise amount of fuel. This is particularly important in multi-cylinder engines where uniform fuel distribution is essential for balanced combustion and engine performance.

Compatibility with Performance Parts

When upgrading to performance parts such as a cold air intake, performance ECU, or aftermarket exhaust, the 3058802 Injector must be capable of handling the increased airflow and fuel demands. These modifications often require injectors with higher flow rates to maintain the correct air-fuel ratio, preventing issues such as lean conditions or engine knock.

Integration with Turbocharger or Supercharger

In forced induction systems, the 3058802 Injector must be able to deliver fuel in greater quantities to match the increased air volume from the turbocharger or supercharger. This ensures that the engine maintains an optimal air-fuel ratio under boost, maximizing power output while safeguarding engine integrity.

Role in Direct Injection Systems

In direct injection engines, the 3058802 Injector sprays fuel directly into the combustion chamber rather than the intake port. This method allows for more precise control over the fuel delivery, enhancing combustion efficiency and reducing emissions. The injector must be designed to withstand higher pressures and temperatures associated with direct injection.

Interaction with Fuel Pump and Regulator

The fuel pump supplies pressurized fuel to the rail, while the fuel regulator maintains a consistent pressure. The 3058802 Injector relies on this stable pressure to deliver fuel accurately. Any fluctuations in fuel pressure can affect the injector’s performance, leading to inefficient combustion and potential engine issues.

Conclusion

By understanding the interplay between the Cummins 3058802 Injector and these components, engineers and mechanics can better diagnose issues, optimize performance, and ensure the longevity of the engine system.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.