This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Cup, identified by part number 3052630, is a critical component in the fuel injection system of heavy-duty trucks. It ensures the proper functioning of fuel injectors by maintaining fuel pressure and providing a seal that prevents fuel leakage. This part enhances the efficiency and reliability of the engine’s fuel delivery system.

Function and Operation

The Cummins Injector Cup secures the injector in place and creates a seal that maintains fuel pressure. It interfaces with the injector and the engine block, ensuring that fuel is delivered at the correct pressure and timing. This component contributes to the overall efficiency of the fuel injection process by preventing fuel leaks and ensuring consistent fuel delivery to the combustion chamber.

Key Features

The Cummins Injector Cup is constructed from high-strength materials and is engineered to withstand the high pressures and temperatures within the fuel injection system. Its design includes precise tolerances to ensure a tight seal and reliable operation under demanding conditions.

Benefits of Using Cummins Injector Cups

Utilizing Cummins Injector Cups offers several advantages, including improved engine performance due to consistent fuel delivery, enhanced reliability from the robust design, and increased longevity of the fuel injection system components. The use of high-quality Injector Cups contributes to the overall efficiency and durability of the engine.

Common Issues and Troubleshooting

Injector Cups may encounter issues such as leaks or failure to seal properly, which can lead to decreased engine performance or fuel efficiency. Symptoms of Injector Cup failure may include engine misfires, reduced power, or increased fuel consumption. Diagnosis typically involves inspecting the Injector Cup for signs of wear or damage and performing pressure tests to identify leaks. Resolution may require replacement of the faulty Injector Cup to restore proper function.

Maintenance and Replacement Guidelines

To maintain optimal engine performance, regular inspection of Injector Cups is recommended. Signs of wear or damage should be addressed promptly to prevent further issues. Replacement procedures should follow manufacturer guidelines to ensure proper installation and function. Attention to torque settings and alignment during replacement is crucial to maintain the integrity of the fuel injection system.

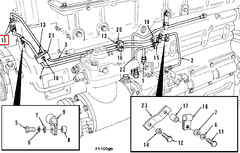

Installation Process

The correct installation of the Cummins Injector Cup involves several steps to ensure proper function. It begins with the preparation of the engine block and injector, followed by the careful placement of the Injector Cup. Proper torque settings must be applied to secure the Injector Cup in place, and alignment checks should be performed to confirm correct installation. This process ensures that the Injector Cup will perform its intended function effectively.

Compatibility and Usage

The Cummins Injector Cup is designed for use in specific engines and models, with compatibility information available from Cummins or through detailed application guides. It is important to consult these resources to ensure the correct Injector Cup is selected for the intended application.

Historical Development

The technology behind Injector Cups has evolved over the years, with Cummins playing a significant role in innovation. Advances in materials and design have led to improvements in durability, performance, and compatibility with modern fuel injection systems. Cummins continues to refine Injector Cup technology to meet the demands of today’s heavy-duty engines.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong presence in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product line includes engines, filtration, emissions solutions, and related technologies, making it a key player in the industry.

Cummins Injector Cup Part 3052630 Compatibility

The Cummins Injector Cup part number 3052630 is designed to fit seamlessly within several engine models. This part is engineered to ensure optimal performance and reliability, making it a vital element in the engine’s fuel injection system.

N14 Mechanical Engine

In the N14 Mechanical engine, the injector cup part 3052630 plays a significant role in the fuel delivery process. This engine, known for its robust design and durability, relies on precision components like the injector cup to maintain its operational efficiency. The injector cup ensures that fuel is delivered accurately and consistently, contributing to the engine’s overall performance.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines benefit from the use of the Cummins Injector Cup part number 3052630. These engines, which are part of the Cummins lineup, are designed for heavy-duty applications and require high-quality components to function effectively. The injector cup in these engines is essential for maintaining the correct fuel-air mixture, which is critical for performance and efficiency. Its design ensures that the fuel is injected into the combustion chamber at the precise moment, enhancing the engine’s power output and fuel economy.

The compatibility of the injector cup part 3052630 across these engines underscores its versatility and importance in the Cummins engine family. Whether in the N14 Mechanical engine or the NH/NT 855 engines, this component is engineered to meet the stringent demands of these high-performance engines, ensuring reliable and efficient operation.

Role of Part 3052630 Injector Cup in Engine Systems

The injector cup, specifically part 3052630, is an integral component within the fuel injection system of an engine. It serves as a protective sleeve that encases the injector tip, ensuring a secure and precise fit within the cylinder head. This part is designed to withstand the high pressures and temperatures generated during the fuel injection process.

In conjunction with the connecting rod and piston, the injector cup plays a significant role in maintaining the integrity of the combustion process. The connecting rod and piston are responsible for converting the force generated by the combustion of fuel into mechanical energy, which drives the engine. The injector cup ensures that the fuel is delivered efficiently and precisely into the combustion chamber, optimizing the performance of these components.

The injector itself relies on the injector cup to maintain a seal and prevent fuel leakage. This is particularly important in high-performance engines where even minor leaks can lead to significant drops in efficiency and power output. The injector cup also helps in dissipating heat away from the injector tip, prolonging the lifespan of the injector and enhancing overall engine reliability.

When considering performance parts, the injector cup is often overlooked but is essential for maximizing the potential of upgraded injectors. High-performance injectors require a robust and precise fitting to operate at their peak, and the injector cup provides this necessary interface.

The top stop (step) injector design benefits significantly from the injector cup. This type of injector uses a stepped design to control the spray pattern and fuel delivery. The injector cup ensures that the injector maintains its position and alignment within the cylinder head, which is vital for consistent fuel delivery and combustion efficiency.

Conclusion

Part 3052630 injector cup is a fundamental component that enhances the functionality and performance of the fuel injection system. Its role in protecting the injector, ensuring precise fuel delivery, and supporting high-performance applications makes it an essential part of modern engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.