This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

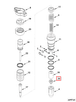

The Cummins Injector Cup, part number 3042713, is a critical component in the operation of heavy-duty diesel engines. Cummins, a prominent figure in the automotive industry, specializes in diesel engines and related components. This part is engineered to enhance the functionality and efficiency of diesel engines, particularly within the fuel injection system 1.

Basic Concepts of Injector Cups

An injector cup is a vital component within the fuel injection system of a diesel engine. Its primary role is to seal the fuel injector within the cylinder head, ensuring efficient fuel delivery under the correct pressure to the combustion chamber. This sealing mechanism is essential for maintaining fuel pressure integrity and preventing leaks, which can adversely affect engine performance and efficiency 2.

Purpose of the 3042713 Injector Cup

The 3042713 Injector Cup is designed to seal the injector within the cylinder head, maintaining the integrity of fuel pressure. This ensures that fuel is delivered to the combustion chamber under optimal conditions, contributing to the engine’s overall performance. Additionally, the cup aids in dissipating heat from the injector, which is crucial for the injector’s longevity and reliability 3.

Key Features

This Cummins part is characterized by its robust design and material composition. It is made from high-quality materials that offer durability and resistance to the high temperatures and pressures present in a diesel engine. The cup’s design includes features that enhance its sealing capabilities and heat dissipation properties, contributing to its performance and longevity.

Benefits

The use of the 3042713 Injector Cup in a diesel engine offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered under optimal pressure and without leaks. This efficient fuel delivery also enhances engine performance, allowing for smoother operation and potentially increased power output. Additionally, the cup’s durable construction and effective sealing capabilities increase the reliability of the fuel injection system, reducing the likelihood of failures and the need for repairs.

Installation Process

Installing the 3042713 Injector Cup requires careful attention to detail to ensure proper function and longevity. The process involves preparing the cylinder head by cleaning the injector seat and ensuring it is free of debris. The cup is then positioned within the injector seat and secured according to the manufacturer’s specifications. This may involve the use of specific tools to ensure the cup is seated correctly and tightly, without damaging the component or the cylinder head.

Common Issues and Troubleshooting

Injector cups, including the 3042713, can encounter issues such as leaks or failures over time. These problems can arise from wear, improper installation, or exposure to extreme conditions. Troubleshooting these issues involves inspecting the cup and the injector seat for signs of damage or wear. In some cases, the cup may need to be replaced, or the injector seat may require resurfacing to ensure a proper seal.

Maintenance Tips

Regular maintenance of the 3042713 Injector Cup is important for ensuring optimal performance and longevity. This includes periodic inspection of the cup and the injector seat for signs of wear or damage. Cleaning the cup and the injector seat as part of routine engine maintenance can also help prevent issues related to debris or contamination. Following the manufacturer’s recommendations for inspection intervals and maintenance procedures is crucial for maintaining the integrity of the fuel injection system.

Cummins Corporation

Cummins Corporation is a leading manufacturer in the automotive industry, with a strong reputation for producing high-quality diesel engines and components. Founded in 1919, Cummins has a long history of innovation and excellence in the design and production of diesel engines, generator sets, and related technologies. The company’s product range includes a variety of engines and components designed for heavy-duty applications, reflecting its commitment to quality and performance in the automotive industry.

Cummins Injector Cup 3042713 Compatibility

The Cummins Injector Cup part number 3042713 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is crucial for the proper functioning of the fuel injection system in these engines.

K38 and K50 Engines

The Injector Cup 3042713 is compatible with the K38 and K50 engines. These engines are known for their robust design and efficiency, making them suitable for various applications. The injector cup ensures that the fuel is delivered precisely to the combustion chamber, enhancing the engine’s performance and fuel efficiency.

QSK19 CM500 Engine

The QSK19 CM500 engine also benefits from the use of the Injector Cup 3042713. This engine is part of the Cummins QSK series, which is renowned for its power and reliability. The injector cup plays a vital role in maintaining the engine’s performance by ensuring that the fuel injection process is smooth and consistent.

Grouping of Engines

The compatibility of the Injector Cup 3042713 across the K38, K50, and QSK19 CM500 engines highlights its versatility and importance in the Cummins engine lineup. This part is engineered to meet the specific requirements of these engines, ensuring that they operate at peak efficiency.

Role of Part 3042713 Injector Cup in Engine Systems

The 3042713 Injector Cup is a specialized component that plays a significant role in the efficient operation of various engine systems. Its primary function is to ensure a secure and reliable seal between the injector and the cylinder head, which is essential for maintaining optimal fuel injection performance.

Integration with Aftercooler Plumbing

In engines equipped with aftercooler plumbing, the 3042713 Injector Cup contributes to the overall efficiency by ensuring that the fuel injection process is precise and consistent. This is particularly important in turbocharged engines where the air charge is cooled before entering the combustion chamber. A well-sealed injector cup helps maintain the integrity of the fuel delivery system, thereby enhancing the performance of the aftercooler system.

Interaction with the Engine Cover

The engine cover serves as a protective enclosure for the internal components, including the injectors. The 3042713 Injector Cup, by providing a robust seal, helps in maintaining the pressure integrity within the engine bay. This is vital for the cover to perform its function effectively, safeguarding the engine from external contaminants and ensuring that the internal pressures are maintained at optimal levels.

Coordination with the Oil Pan

The oil pan is responsible for storing and circulating engine oil, which is crucial for lubrication and cooling. The 3042713 Injector Cup, while primarily focused on fuel injection, indirectly supports the oil pan’s function by ensuring that the engine operates smoothly. A properly sealed injector reduces the likelihood of fuel leaks, which could otherwise contaminate the oil and compromise its lubricating properties.

Synergy with Injectors and Performance Parts

Injectors are the heart of the fuel delivery system, responsible for spraying fuel into the combustion chamber at the precise moment. The 3042713 Injector Cup ensures that this process is seamless by providing a reliable seal. When combined with high-performance parts, such as upgraded injectors or performance fuel rails, the injector cup enhances the overall efficiency and responsiveness of the fuel system. This synergy is particularly beneficial in performance-oriented engines where every millisecond and every drop of fuel count towards achieving peak performance.

Impact on Overall Engine Performance

The role of the 3042713 Injector Cup extends beyond individual components; it significantly impacts the overall engine performance. By ensuring a secure and consistent seal, it contributes to better fuel atomization, more efficient combustion, and ultimately, enhanced engine power and efficiency. This is especially noticeable in high-performance engines where the margins between optimal and suboptimal performance are narrow.

Conclusion

The 3042713 Injector Cup is a vital component that interacts with various engine systems to ensure efficient and reliable operation. Its role in maintaining seals and supporting the function of other components underscores its importance in both standard and high-performance engine applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.