This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Injector Top Level Assembly Lever, identified by Part #3034789, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This lever is integral to the fuel injection system of heavy-duty trucks, facilitating precise fuel delivery to the engine. Cummins, known for its robust and reliable parts, ensures that this lever meets the demanding requirements of heavy-duty applications 1.

Function and Operation

The Injector Top Level Assembly Lever operates within the fuel injection system by controlling the injection process. It interacts with other components such as the injector pump and nozzle to regulate the timing and quantity of fuel delivered to the engine cylinders. This precise control is vital for optimal engine performance, ensuring that fuel is delivered at the right moment and in the correct amount to achieve efficient combustion 2.

Key Features

The Injector Top Level Assembly Lever is designed with several key features that enhance its performance and durability. Constructed from high-strength materials, it is built to withstand the rigors of heavy-duty use. Its design includes precise machining and tolerances to ensure smooth operation and reliable performance. Additionally, the lever incorporates features that reduce friction and wear, contributing to its longevity and consistent operation 3.

Benefits

The advantages provided by the Injector Top Level Assembly Lever include improved fuel efficiency, enhanced engine performance, and reliability in heavy-duty applications. By ensuring precise fuel delivery, the lever helps to optimize combustion, leading to better fuel economy and reduced emissions. Its robust construction and reliable operation contribute to the overall durability and performance of the engine, making it a valuable component in heavy-duty truck fuel systems 4.

Installation and Maintenance

Proper installation of the Injector Top Level Assembly Lever is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, with attention to torque specifications and alignment. Regular maintenance practices, such as inspecting for wear and ensuring all connections are secure, are recommended to maintain the lever’s performance. Additionally, keeping the fuel system clean and free of contaminants will help prevent issues related to the lever and other components 5.

Troubleshooting

Common problems associated with the Injector Top Level Assembly Lever may include misfiring, reduced engine performance, or irregular fuel delivery. Diagnostic procedures for identifying issues may involve checking for proper installation, inspecting for wear or damage, and ensuring that all connections are secure. Recommended solutions or repairs may include adjusting the lever, replacing worn components, or cleaning the fuel system to remove contaminants 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. Their product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of various applications 7.

Cummins Injector Top Level Assembly Lever (Part 3034789) Compatibility

The Cummins Injector Top Level Assembly Lever, identified by part number 3034789, is a critical component in the fuel injection system of various engines. This part is designed to ensure precise control over the fuel delivery process, which is essential for maintaining optimal engine performance and efficiency.

L10 CELECT Engine

In the L10 CELECT engine, the Injector Top Level Assembly Lever plays a pivotal role in the electronic fuel injection system. This engine variant is known for its advanced electronic controls, which rely on precise mechanical components to function correctly. The lever ensures that the injector operates smoothly, allowing for the accurate metering of fuel into the combustion chamber. This is crucial for achieving the desired power output and fuel efficiency.

L10 MECHANICAL Engine

For the L10 MECHANICAL engine, the Injector Top Level Assembly Lever is equally important, though it operates within a more traditional mechanical fuel injection system. This engine relies on mechanical linkages and hydraulic systems to control fuel delivery. The lever in this context ensures that the injector can open and close at the correct times, which is vital for maintaining the engine’s performance and responsiveness. The mechanical nature of this engine means that the lever must be robust and durable, capable of withstanding the rigors of continuous operation.

Grouping of Engines

Both the L10 CELECT and L10 MECHANICAL engines share a common requirement for the Injector Top Level Assembly Lever to function correctly. Despite the differences in their control systems, the fundamental role of the lever remains the same: to facilitate the precise operation of the fuel injector. This commonality underscores the importance of using a high-quality, reliable component like the Cummins part number 3034789 to ensure that both engine types can perform at their best.

Understanding the Role of Part 3034789 Injector Top Level Assembly Lever in Engine Systems

The Injector Top Level Assembly Lever, identified by part number 3034789, is an integral component within the fuel injection system of an engine. Its primary function is to facilitate the precise control of fuel injection timing and quantity, which are essential for optimal engine performance and efficiency.

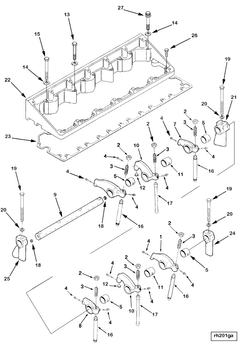

Interaction with Base Parts

At the foundational level, the Injector Top Level Assembly Lever interacts with the base parts of the fuel injection system. These base parts typically include the injector body and the nozzle holder. The lever’s movement, driven by the camshaft or other mechanical means, translates into the opening and closing of the injector nozzle. This action allows fuel to be sprayed into the combustion chamber at the exact moment required for efficient combustion.

Coordination with the Lever

The lever component of the assembly is directly actuated by the camshaft lobe or a similar mechanical driver. As the camshaft rotates, it imparts motion to the lever, which in turn controls the injector plunger. This plunger movement is what ultimately determines the start and end of the fuel injection process. The precision of this lever’s operation is vital for maintaining the engine’s fuel efficiency and emissions standards.

Integration with the Rocker

In many engine designs, the Injector Top Level Assembly Lever is connected to a rocker mechanism. The rocker serves as an intermediary that amplifies the motion from the camshaft to the lever. This amplification ensures that the lever moves with sufficient force to overcome the spring pressure within the injector, allowing for a clean and precise fuel injection event. The rocker’s design can vary, with some systems employing a direct-acting rocker and others using a more complex linkage system.

Synergy with the Rocker Lever

The rocker lever, often a part of the rocker assembly, plays a supporting role in the injection process. It ensures that the motion from the camshaft is transferred efficiently to the Injector Top Level Assembly Lever. The design of the rocker lever can influence the injection timing and duration, making it a key component in fine-tuning the engine’s performance characteristics.

Conclusion

In summary, the Injector Top Level Assembly Lever (part 3034789) works in concert with the base parts, lever, rocker, and rocker lever to ensure that fuel is injected into the engine at the precise moment and in the correct quantity. This harmonious interaction is fundamental to the engine’s overall performance, fuel efficiency, and emissions control.

-

TK Garrett, K Newton, W Steeds, The Motor Vehicle, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Rudolf Limpert, Brake Design and Safety, Third Edition, SAE International, 2011.

↩ -

Michael Hilgers, Chassis and Axles, Springer Vieweg, 2023.

↩ -

Michael Klyde and Kirk VanGelder, Advanced Automotive Electricity and Electronics, Jones Bartlett Learning, 2010.

↩ -

Cummins Inc., ISF3.8 CM2350 F109 Owners Manual, Bulletin Number 4367220.

↩ -

Cummins Inc., ISF3.8 CM2350 F109 Owners Manual, Bulletin Number 4367220.

↩ -

Cummins Inc., ISF3.8 CM2350 F109 Owners Manual, Bulletin Number 4367220.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.