This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

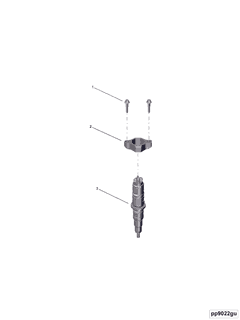

The Injector Plunger Link (Part #3028448) manufactured by Cummins is a critical component in diesel engine fuel injection systems. Specifically designed for commercial trucks, this part ensures precise fuel delivery, which is essential for optimal engine performance and efficiency 1.

Function and Operation

The Injector Plunger Link transfers motion from the camshaft to the injector plunger, ensuring that fuel is delivered accurately and reliably into the engine’s combustion chamber. This precise timing is vital for maintaining engine performance and efficiency 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, contributing to its durability and precision engineering. It is engineered to withstand the demanding conditions within a diesel engine, ensuring long-term reliability. The link is designed for compatibility with Cummins engines, ensuring seamless integration and optimal performance. Its precision-machined components allow for accurate motion transfer, which is essential for the efficient operation of the fuel injection system 3.

Benefits

The Injector Plunger Link offers several advantages, including improved fuel efficiency and enhanced engine performance. By ensuring precise fuel delivery, it helps maintain consistent engine operation under varying load conditions, resulting in better overall fuel economy and reduced emissions. Additionally, the reliable operation of the link contributes to the longevity of the fuel injection system, reducing the need for frequent maintenance and replacements.

Installation and Maintenance

Proper installation of the Injector Plunger Link is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it functions correctly within the fuel injection system. Routine maintenance practices, such as regular inspections for wear and proper lubrication, are recommended to ensure the longevity and optimal performance of the link. Following these maintenance practices can help prevent issues and ensure the component continues to operate efficiently.

Troubleshooting Common Issues

Common problems associated with the Injector Plunger Link may include wear, misalignment, or failure. These issues can lead to inconsistent fuel delivery and reduced engine performance. Troubleshooting these problems involves inspecting the link for signs of wear or damage, ensuring it is properly aligned with the camshaft and injector plunger, and replacing it if necessary. Adhering to the manufacturer’s guidelines for maintenance and replacement can help mitigate these issues.

Safety Considerations

When working with the Injector Plunger Link, it is important to follow safety precautions and best practices. This includes proper handling of the component to avoid damage, adhering to torque specifications during installation, and following manufacturer guidelines for maintenance and replacement. These practices ensure the safe and effective operation of the fuel injection system and contribute to the overall safety of the vehicle.

Cummins Corporation

Cummins Inc. is a leading manufacturer of diesel engines and components, with a history of innovation in diesel engine technology. The company offers a wide range of products designed to meet the needs of various industries, including commercial trucking. Cummins is committed to providing high-quality, reliable components that contribute to the efficient and effective operation of diesel engines. The Injector Plunger Link (Part #3028448) is a testament to Cummins’ dedication to engineering excellence and customer satisfaction.

Compatibility

The Injector Plunger Link part number 3028448 is compatible with various diesel engines, including the K19, K38, and K50 engines. This part ensures the proper operation of the injectors by maintaining the correct linkage between the injector plunger and the fuel injector body.

K19 Engine

In the K19 engine, 3028448 plays a pivotal role in the fuel injection mechanism. It ensures that the injector plunger moves smoothly and accurately, which is essential for delivering the precise amount of fuel at the correct timing. This part is integral to maintaining the engine’s performance and efficiency.

K38 and K50 Engines

Similarly, for the K38 and K50 engines, 3028448 is a vital component. These engines rely on the precise movement of the injector plunger to inject fuel into the combustion chamber. The link ensures that the injector operates as intended, contributing to the overall reliability and performance of the engine.

The compatibility of 3028448 across these engines highlights its importance in the fuel injection system. Ensuring that this part is correctly installed and functioning is crucial for the smooth operation of the engines.

Understanding the Role of Injector Plunger Link in Engine Systems

The Injector Plunger Link, identified by part number 3028448, is an integral component in the operation of fuel injection systems within various engine setups. This link is responsible for transmitting motion from the camshaft to the injector plunger, ensuring precise fuel delivery.

Integration with Injector Components

When the camshaft rotates, it actuates the Injector Plunger Link, which in turn moves the injector plunger. This motion is essential for the injector to open and close at the correct timing, allowing fuel to be sprayed into the combustion chamber in a controlled manner. The accuracy of this process is vital for maintaining engine performance and efficiency.

Interaction with Performance Parts

In high-performance engine setups, the Injector Plunger Link plays a significant role. Upgraded performance parts often require modifications to the fuel injection system to handle increased fuel demands. The Injector Plunger Link must be capable of withstanding higher pressures and more frequent cycles without failure, ensuring that the injector can deliver the necessary fuel volume and pressure for optimal performance.

Role in Top-Stop Injector Systems

Top-stop injectors, which are commonly used in diesel engines, rely on the Injector Plunger Link to maintain the integrity of the injection process. These injectors have a stop mechanism at the top of the plunger that limits the travel distance, ensuring consistent fuel delivery. The link must be precisely machined and installed to ensure that the stop mechanism functions correctly, preventing over-injection or under-injection of fuel.

Ensuring Consistent Performance

The consistent operation of the Injector Plunger Link is essential for the reliable performance of the entire fuel injection system. Any deviation in the link’s performance can lead to issues such as misfires, reduced power output, or increased emissions. Therefore, regular inspection and maintenance of this component are recommended to ensure it continues to function within specified parameters.

Conclusion

The Injector Plunger Link (part 3028448) is a key element in the fuel injection system, facilitating the precise delivery of fuel to the engine’s combustion chambers. Its proper function is essential for both standard and high-performance engine operations, making it a component of significant importance in engine maintenance and upgrade processes.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.