This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

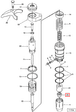

The Cummins Injector Cup, identified by Part #3024148, is a component integral to the fuel injection system of heavy-duty trucks. Its purpose is to ensure the proper functioning of the fuel injector within the cylinder head, contributing significantly to the engine’s overall performance and efficiency.

Basic Concepts of Injector Cups

An injector cup is a cylindrical component that houses the fuel injector within the cylinder head of an engine. Its primary function is to provide a secure seal around the injector, preventing fuel leakage into the cylinder and ensuring that fuel pressure is maintained effectively. This seal is vital for the precise delivery of fuel into the combustion chamber, which directly influences the engine’s performance and efficiency 1.

Purpose of the Cummins Injector Cup

The Cummins Injector Cup plays a role in the operation of a truck by sealing the injector within the cylinder head and maintaining the integrity of fuel pressure. This ensures that fuel is delivered to the combustion chamber in a controlled and efficient manner, which is crucial for optimal engine performance. By providing a reliable seal, the injector cup helps to prevent fuel leaks and maintain the necessary pressure for efficient fuel injection 2.

Key Features of the Cummins Injector Cup

The Cummins Injector Cup is characterized by several key features that enhance its performance and durability. These include its material composition, which is designed to withstand the high pressures and temperatures within the engine, and its precise design specifications that ensure a secure fit within the cylinder head. Additionally, the injector cup may feature unique attributes such as reinforced structures or specialized coatings to further improve its resistance to wear and corrosion 3.

Benefits of Using the Cummins Injector Cup

Utilizing the Cummins Injector Cup offers several advantages. These include improved fuel efficiency due to the precise control of fuel delivery, enhanced engine performance resulting from optimal fuel injection, and increased reliability under demanding operating conditions. The robust design and high-quality materials of the injector cup contribute to its longevity and effectiveness in heavy-duty applications.

Installation and Maintenance

Proper installation of the Cummins Injector Cup is crucial for ensuring optimal performance. This involves carefully positioning the cup within the cylinder head and securing it in place according to manufacturer specifications. Regular maintenance practices, such as inspecting for signs of wear or damage and ensuring the integrity of the seal, are recommended to maintain performance. Additionally, addressing common issues promptly can help prevent more significant problems down the line.

Troubleshooting Common Issues

Frequent problems associated with injector cups may include leaks or failures, which can lead to decreased engine performance or fuel efficiency. Troubleshooting these issues involves identifying the source of the problem, whether it be a faulty seal, damage to the cup, or issues with the injector itself. Effective diagnosis and resolution may require disassembling the injector cup, inspecting for damage, and replacing any compromised components to restore proper function.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation within the automotive and heavy-duty truck industries. The company’s extensive product offerings and commitment to excellence have made it a trusted name among professionals and enthusiasts alike.

Injector Cup (Part 3024148) in Cummins Engines

The Injector Cup, identified by the part number 3024148, is a critical component in the Cummins N14 MECHANICAL engine. This part is integral to the engine’s fuel injection system, ensuring precise fuel delivery to the combustion chamber.

In the Cummins N14 MECHANICAL engine, the Injector Cup works in conjunction with the fuel injector to atomize and deliver fuel at high pressure. This process is essential for achieving optimal combustion efficiency and power output. The Injector Cup’s design and material are specifically engineered to withstand the extreme conditions within the engine, including high temperatures and pressures.

The Injector Cup is also compatible with other Cummins engines within the same family, ensuring a standardized fit and function across multiple engine models. This standardization simplifies maintenance and repair processes, as technicians can use the same part across different engine types.

For the N14 MECHANICAL engine, the Injector Cup’s role is pivotal in maintaining the engine’s performance and reliability. Its precise fit and function are crucial for the overall efficiency and longevity of the engine.

Role of Part 3024148 Injector Cup in Engine Systems

The Injector Cup, identified by part number 3024148, is an integral component in the operation of various engine systems. Its primary function is to provide a secure and efficient interface between the injector and the cylinder head. This ensures that fuel is delivered precisely and consistently into the combustion chamber.

In the context of injector systems, the Injector Cup plays a significant role in maintaining the integrity of the fuel delivery process. It helps to seal the injector within the cylinder head, preventing fuel leaks and ensuring that the fuel is injected at the correct pressure and timing. This is particularly important in high-performance engines where precision and reliability are paramount.

When considering TP-STP Less Link components, the Injector Cup contributes to the overall performance by ensuring that the injector operates within its designed parameters. This is essential for maintaining engine efficiency and reducing the risk of damage due to improper fuel injection.

In the realm of performance parts, the Injector Cup is often overlooked but is equally important. High-performance engines demand components that can withstand increased stress and deliver consistent performance. The Injector Cup, by ensuring a reliable seal and proper injector function, helps to achieve the desired performance levels without compromising engine health.

For Top-Stop Injector systems, the Injector Cup is vital in maintaining the correct seating of the injector. This is crucial for the injector to function as intended, delivering fuel in a manner that optimizes combustion and power output. The cup’s design and material properties are tailored to handle the specific demands of top-stop injectors, ensuring they perform efficiently under various operating conditions.

Overall, the Injector Cup (part 3024148) is a foundational component in the intricate dance of engine systems, contributing to the reliability, performance, and efficiency of the engine.

Conclusion

The Cummins Injector Cup, part number 3024148, is a vital component in the fuel injection system of heavy-duty engines. Its role in ensuring a secure seal, maintaining fuel pressure, and facilitating precise fuel delivery is crucial for engine performance and efficiency. The robust design and high-quality materials of this Cummins part contribute to its durability and effectiveness in demanding applications. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential practices to ensure the longevity and optimal performance of the Injector Cup in engine systems.

-

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.