This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3018575 Injector is a component designed for use in commercial trucks, playing a significant role in the efficient operation of these vehicles. This injector is part of the fuel system, responsible for delivering fuel into the engine’s combustion chambers. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications, ensuring reliable performance and efficiency in various operating conditions.

Basic Concepts of Fuel Injectors

Fuel injectors are devices used in internal combustion engines to deliver fuel into the combustion chamber. They operate by atomizing fuel into a fine mist, which mixes with air before ignition. This process is crucial for efficient combustion, as it ensures that the fuel burns completely, maximizing energy output and minimizing emissions 1. The precision of fuel delivery provided by injectors allows for better control over the combustion process, leading to improved engine performance and fuel efficiency.

Purpose of the Cummins 3018575 Injector

The Cummins 3018575 Injector serves a pivotal role in the operation of a truck by facilitating the precise delivery of fuel into the engine’s combustion chambers. This injector is engineered to enhance combustion efficiency, ensuring that fuel is atomized and distributed evenly for optimal burning. By doing so, it contributes to the overall performance of the engine, including its power output, fuel economy, and emission levels.

Key Features

The Cummins 3018575 Injector is characterized by several key features that enhance its performance. Its design incorporates advanced technology to ensure precise fuel delivery. The materials used in its construction are selected for durability and resistance to the high pressures and temperatures encountered in diesel engines. Additionally, this injector benefits from technological advancements that improve its efficiency and reliability, making it a suitable choice for heavy-duty applications.

Benefits of Using the Cummins 3018575 Injector

Utilizing the Cummins 3018575 Injector offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered in the most effective manner possible. This results in better engine performance, as the precise fuel delivery enhances combustion efficiency. Furthermore, the use of this injector can lead to reduced emissions, as the optimized combustion process minimizes the production of pollutants 2.

Installation and Integration

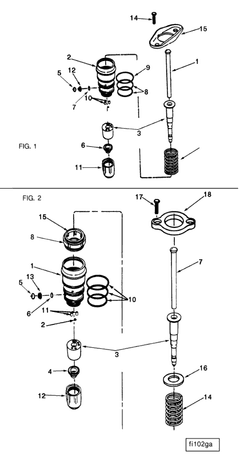

Proper installation of the Cummins 3018575 Injector is crucial for its effective operation. The installation process involves several steps, including the preparation of the engine compartment and the careful fitting of the injector into its designated port. It is important to follow manufacturer guidelines to ensure that the injector is securely and correctly installed, allowing for optimal performance and longevity.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3018575 Injector is important for its continued efficient operation. This includes regular inspections for signs of wear or damage, as well as cleaning or replacing components as necessary. Troubleshooting common issues may involve checking for leaks, ensuring proper fuel delivery, and addressing any performance concerns that arise. Adhering to a maintenance schedule can help prevent more serious problems and extend the life of the injector.

Performance Optimization

To maximize the performance of the Cummins 3018575 Injector, it is beneficial to fine-tune fuel delivery parameters. This may involve adjusting settings to match the specific requirements of the engine and operating conditions. Addressing potential performance bottlenecks, such as ensuring clean fuel and proper air intake, can also contribute to optimal injector performance. Regular monitoring and adjustment can help maintain peak efficiency and reliability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability within the automotive industry. The company’s product offerings cater to various sectors, including commercial vehicles, industrial applications, and power generation, demonstrating its commitment to meeting the diverse needs of its customers.

Role of Part 3018575 Injector in Engine Systems

The 3018575 Injector is a pivotal component in the fuel delivery system of an engine, ensuring precise fuel atomization and delivery. This injector works in concert with several other components to optimize engine performance and efficiency.

Fuel Rail Integration

The 3018575 Injector is mounted on the fuel rail, a component that distributes pressurized fuel to each injector. The injector’s nozzle opens and closes in response to signals from the Engine Control Unit (ECU), allowing it to spray fuel into the combustion chamber at the exact moment required.

ECU Communication

The Engine Control Unit (ECU) plays a significant role in the operation of the 3018575 Injector. The ECU monitors various engine parameters such as engine speed, load, and temperature. Based on this data, it sends signals to the injector to control the duration and timing of fuel injection, ensuring optimal combustion.

Combustion Chamber Interaction

Once the 3018575 Injector releases fuel into the combustion chamber, it interacts with the air-fuel mixture. The injector’s design ensures that fuel is atomized into fine particles, promoting efficient mixing with air and complete combustion. This interaction directly influences engine power output and fuel efficiency.

Throttle Body Coordination

The throttle body regulates the amount of air entering the engine. The 3018575 Injector must coordinate with the throttle body to maintain the correct air-fuel ratio. This coordination is essential for smooth engine operation and responsiveness.

Oxygen Sensor Feedback

Oxygen sensors monitor the exhaust gases to determine the air-fuel ratio. The data from these sensors is sent back to the ECU, which then adjusts the 3018575 Injector’s operation to maintain optimal combustion efficiency. This feedback loop is vital for reducing emissions and improving fuel economy.

Performance Parts Enhancement

In engines equipped with performance parts such as cold air intakes or performance exhaust systems, the 3018575 Injector must be capable of handling increased airflow and fuel demands. The injector’s precise fuel delivery ensures that these performance enhancements result in improved engine output without compromising reliability.

Overall Engine Efficiency

The 3018575 Injector’s role extends beyond individual components; it is integral to the overall efficiency of the engine. By ensuring that fuel is delivered at the right time and in the right amount, the injector helps to maximize power output while minimizing fuel consumption and emissions.

Conclusion

The Cummins 3018575 Injector is a critical component in the fuel delivery system of commercial trucks, designed to enhance engine performance, fuel efficiency, and reduce emissions. Its advanced features and precise fuel delivery capabilities make it an essential part of heavy-duty applications. Proper installation, maintenance, and optimization are key to maximizing the benefits of this Cummins part, ensuring reliable and efficient engine operation.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.