This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

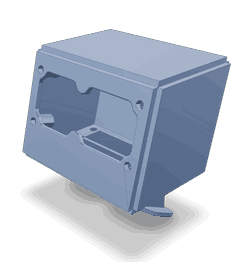

The Cummins 4967621 Breather Chamber is a component designed to facilitate proper ventilation and pressure equalization within the engine system of heavy-duty trucks. Its role is significant in ensuring the engine operates efficiently and maintains longevity.

Basic Concepts and Functionality

A breather chamber is a part of the engine system that allows for the equalization of pressure and the release of gases that accumulate within the engine’s crankcase. It operates on the principles of pressure equalization and ventilation, ensuring that the internal pressure within the engine does not exceed safe levels, which could lead to leaks or damage 1.

Purpose of the 4967621 Breather Chamber

This Cummins part plays a role in the operation of a truck by maintaining optimal engine performance and longevity. It ensures that the engine’s internal pressure is regulated, which helps in reducing wear and tear on engine components and enhancing overall engine efficiency 2.

Key Features

The Cummins 4967621 Breather Chamber is characterized by its robust design and the use of high-quality materials that ensure durability and reliable performance. Its design incorporates features that enhance ventilation and pressure equalization, contributing to its effectiveness in maintaining engine health 3.

Benefits

The 4967621 Breather Chamber provides several benefits, including improved engine efficiency through effective pressure management, reduced wear and tear on engine components due to stable internal pressure, and enhanced reliability of the engine system as a whole 4.

Installation Process

Installing the 4967621 Breather Chamber involves several steps to ensure proper fitting and functionality. Preparatory steps include ensuring the engine is clean and free of debris. The necessary tools for installation should be gathered beforehand. The chamber should be aligned correctly with the engine’s ventilation system and secured in place following the manufacturer’s guidelines to ensure a proper seal and function 5.

Maintenance Tips

Regular maintenance of the 4967621 Breather Chamber is important for continued optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the chamber to remove any accumulated debris, and ensuring all connections are secure and free of leaks. Adhering to recommended inspection intervals will help in identifying any issues early on 6.

Troubleshooting Common Issues

Common issues associated with the 4967621 Breather Chamber may include leaks or blockages. Troubleshooting steps involve inspecting the chamber and its connections for any signs of damage or wear, cleaning the chamber to remove obstructions, and ensuring that all components are correctly installed and sealed. Addressing these issues promptly can help in maintaining the efficiency and reliability of the engine system 7.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the heavy-duty truck industry, known for its wide range of engine and power generation products. With a history of innovation and quality, Cummins has built a reputation for producing reliable and efficient engine components, including the 4967621 Breather Chamber 8.

Compatibility

The Cummins Breather Chamber part number 4967621 is designed to fit seamlessly with several Cummins engine models. This part is engineered to ensure optimal engine performance by managing the air flow and pressure within the engine’s crankcase.

QSK19 and CM2350 Engines

The QSK19 and CM2350 engines, both part of Cummins’ robust lineup, benefit significantly from the integration of the 4967621 Breather Chamber. These engines are known for their reliability and efficiency, and the breather chamber plays a pivotal role in maintaining these qualities. By effectively venting and balancing the pressure within the crankcase, the breather chamber helps prevent oil contamination and ensures the longevity of the engine components 9.

K105 Engine

The K105 engine also incorporates the 4967621 Breather Chamber, which is essential for its operation. This engine, designed for heavy-duty applications, relies on the breather chamber to manage the air flow and pressure dynamics within the crankcase. The breather chamber’s design ensures that the engine operates smoothly, even under demanding conditions, thereby enhancing the overall performance and durability of the K105 engine 10.

Integration and Functionality

The integration of the 4967621 Breather Chamber across these engines is a testament to its versatility and effectiveness. This part is meticulously designed to fit the specific requirements of each engine model, ensuring that it performs optimally in various operational environments. The breather chamber’s role in managing air flow and pressure is crucial for maintaining the integrity of the engine’s internal components, thereby contributing to the overall reliability and efficiency of the engines 11.

Role of Part 4967621 Breather Chamber in Engine Systems

The 4967621 Breather Chamber is an integral component in the arrangement of engine systems, specifically interacting with the crankcase breather system. This chamber facilitates the controlled release of gases that accumulate within the crankcase during engine operation.

In the context of the crankcase breather system, the 4967621 Breather Chamber works in conjunction with the crankcase ventilation system to maintain optimal pressure levels within the crankcase. It allows for the safe and efficient venting of gases, which include unburned fuel, combustion byproducts, and moisture, that are produced as byproducts of the combustion process.

The interaction between the 4967621 Breather Chamber and the crankcase breather ensures that these gases are directed away from the engine’s internal components, preventing buildup that could lead to increased pressure, contamination, or even damage to sensitive parts. This venting process is essential for preserving the integrity of the engine’s lubrication system, as it prevents the dilution of engine oil with these unwanted gases.

Furthermore, the 4967621 Breather Chamber plays a role in the overall efficiency and performance of the engine. By managing the crankcase pressure and ensuring that the ventilation system operates smoothly, it contributes to the engine’s ability to maintain consistent power output and operational stability. This component is also involved in reducing emissions, as it helps in the proper handling and routing of gases that would otherwise be released into the atmosphere unchecked.

Conclusion

In summary, the 4967621 Breather Chamber is a key element in the engine’s ventilation system, working alongside the crankcase breather to ensure the engine operates within safe pressure parameters, maintains clean lubrication, and contributes to efficient and environmentally responsible engine performance 12.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Ling, F. F. (2011). The Automotive Body. Springer Science.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411134.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Engine Models Compatibility. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). K105 Engine Specifications. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Breather Chamber Functionality. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411134.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.