This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

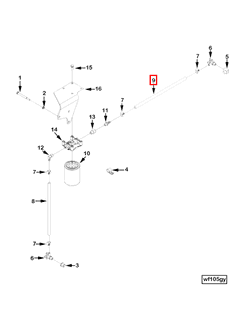

The Cummins 179917 Plain Hose is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance can help in maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Plain Hoses

Plain hoses are flexible tubes used to transport fluids in various systems. They are commonly employed in automotive and industrial applications due to their ability to accommodate movement and vibration while maintaining a secure fluid pathway. Plain hoses are typically made from synthetic materials that offer resistance to wear, chemicals, and environmental factors 1.

Purpose and Role in Truck Operation

This Cummins part plays a role in the operation of a commercial truck by connecting different systems and facilitating the transport of fluids. It is integral to systems that require fluid transfer, such as coolant, fuel, or hydraulic systems. The hose ensures that fluids are delivered efficiently and without leakage, which is vital for the truck’s performance and longevity.

Key Features

This part is characterized by several key features that enhance its performance. These include a material composition designed for durability and resistance to various fluids, flexibility to accommodate the dynamic movements of a truck, and a robust design that ensures longevity under demanding conditions. These features contribute to the hose’s ability to maintain system integrity and efficiency.

Benefits

Using this Cummins part offers several advantages. It provides improved system efficiency by ensuring a consistent and leak-free fluid pathway. The hose’s design reduces the risk of leaks, which can lead to system failures or inefficiencies. Additionally, its durability ensures that it can withstand the rigors of commercial truck operation, offering a reliable solution for fluid transport.

Installation Considerations

When installing Plain Hose, it is important to follow guidelines and best practices to ensure proper integration with the truck’s systems. This includes using the correct fitting techniques to secure the hose in place, ensuring compatibility with existing systems, and verifying that all connections are tight and secure. Proper installation is key to the hose’s performance and the truck’s overall efficiency.

Troubleshooting Common Issues

Common issues with plain hoses, such as leaks, kinks, and degradation, can arise due to wear and tear or improper installation. Troubleshooting these problems involves inspecting the hose for signs of damage, ensuring that all connections are secure, and replacing the hose if necessary. Regular maintenance can help prevent these issues and ensure the hose continues to function effectively.

Maintenance Tips

To ensure the optimal performance of 179917, regular maintenance is recommended. This includes inspecting the hose at regular intervals for signs of wear or damage, cleaning the hose as needed to remove any buildup that could affect its performance, and replacing the hose when it shows signs of significant wear or failure. Consistent maintenance helps to prolong the life of the hose and maintain system efficiency.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. Cummins is dedicated to powering a more prosperous world by providing reliable and efficient power solutions.

Role of Part 179917 Plain Hose in Engine Systems

179917 is integral to the efficient operation of various engine systems. It facilitates the smooth transfer of fluids, ensuring that components receive the necessary lubrication, cooling, or hydraulic pressure to function optimally.

In the Corrosion Resistor System, the Plain Hose plays a significant role by transporting coolant or other protective fluids. This helps maintain the integrity of the resistor by preventing overheating and corrosion, thereby prolonging its lifespan and ensuring consistent performance.

Within the Corrosion Resistor Sub-Optimal System, the hose is responsible for delivering fluids that help mitigate corrosion in areas where the primary corrosion resistor may not be as effective. This ensures that even in less-than-ideal conditions, the engine components remain protected from corrosive damage.

In the broader Resistor System, the Plain Hose is essential for circulating fluids that help regulate temperature and protect electrical components from damage due to heat or moisture. This ensures that the resistors maintain their efficiency and reliability over time.

For the Corrosion System as a whole, the Plain Hose is a key component in the fluid distribution network. It ensures that anti-corrosive agents reach all necessary points within the engine, safeguarding metal parts from rust and degradation. This is particularly important in environments where the engine is exposed to moisture or salt, such as in marine or industrial applications.

Overall, the effective deployment of 179917 in these systems underscores its importance in maintaining the health and performance of engine components, ensuring they operate within optimal parameters and endure longer service lives.

Conclusion

The Cummins 179917 Plain Hose is a vital component in the fluid systems of commercial trucks, ensuring efficient and reliable operation. Its design, featuring durability, flexibility, and robust construction, contributes to the overall performance and longevity of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring that it continues to function effectively within the truck’s systems.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.