This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

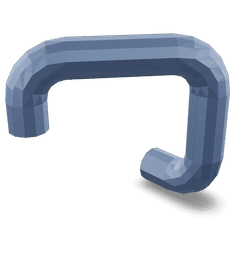

The Cummins 3970877 Molded Hose is a specialized component designed for use in commercial trucks. It plays a role in ensuring the efficient operation of various truck systems by facilitating the transfer of fluids. Understanding its purpose and functionality is key to maintaining the overall performance and reliability of commercial vehicles.

Basic Concepts of Molded Hoses

Molded hoses are engineered components used extensively in automotive and industrial applications. They are constructed by molding synthetic rubber or thermoplastic materials around embedded textile or wire reinforcements. This construction method provides molded hoses with enhanced flexibility, durability, and resistance to various environmental factors. In automotive systems, molded hoses are commonly employed to transport fluids such as coolant, fuel, and hydraulic fluid, contributing to the efficient operation of engines and other critical systems 1.

Purpose of the 3970877 Molded Hose

The Cummins 3970877 Molded Hose is integral to the operation of commercial trucks, connecting specific systems and transporting essential fluids. It is designed to link components within the truck’s fluid systems, ensuring the smooth and reliable transfer of fluids under varying operational conditions. This hose plays a role in maintaining the integrity and performance of the systems it serves by providing a durable and flexible conduit for fluid flow 2.

Key Features

The Cummins 3970877 Molded Hose incorporates several design elements and materials that enhance its performance and durability. It is constructed using high-quality synthetic materials that offer resistance to abrasion, chemicals, and temperature extremes. The hose’s design includes reinforced ends to ensure a secure connection to fittings, reducing the risk of leaks. Additionally, its flexibility allows it to accommodate the movement and vibration inherent in truck operations, further contributing to its longevity and reliability 3.

Benefits

The Cummins 3970877 Molded Hose offers several advantages that contribute to its popularity in the commercial truck industry. Its robust construction and material selection result in improved reliability and resistance to wear and tear. The hose’s design also facilitates ease of installation, allowing for quick replacement or integration into truck systems without the need for specialized tools or equipment 4.

Installation Process

Installing the Cummins 3970877 Molded Hose requires attention to detail to ensure a secure and leak-free connection. The process involves preparing the hose and fittings, aligning the hose with the target connections, and securing it in place. Tools such as hose clamps may be required to achieve a tight seal. Following manufacturer guidelines and best practices during installation is recommended to ensure optimal performance and longevity of the hose 5.

Maintenance Tips

Regular inspection and maintenance of the Cummins 3970877 Molded Hose are crucial for prolonging its lifespan and ensuring optimal performance. Inspecting the hose for signs of wear, cracking, or leaks at regular intervals allows for early detection of potential issues. Cleaning the hose and its connections, as well as ensuring proper lubrication where applicable, can also contribute to its durability and efficiency 6.

Troubleshooting Common Issues

Common problems associated with molded hoses, such as leaks or degradation, can often be traced back to installation errors, environmental factors, or natural wear and tear. Addressing these issues may involve re-securing connections, replacing damaged sections of the hose, or investigating external factors that may be contributing to its degradation. Consulting manufacturer guidelines and seeking professional advice when necessary can aid in effectively resolving these issues 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. Its commitment to advancing technology and meeting the evolving needs of its customers underscores its position as a trusted partner in the automotive and industrial sectors.

Cummins Molded Hose Part 3970877 Compatibility

The Cummins molded hose part number 3970877 is designed to integrate seamlessly with various engine models, ensuring optimal performance and reliability. This hose is engineered to meet the stringent requirements of Cummins engines, providing a durable and flexible solution for fluid transfer applications.

Engine Compatibility

-

B4.5 Engines: The molded hose part 3970877 is specifically engineered to fit the B4.5 engine series. It is designed to handle the unique demands of these engines, ensuring efficient fluid transfer and maintaining system integrity.

-

Other Cummins Engines: While the primary focus is on the B4.5 engines, this molded hose is also compatible with a range of other Cummins engine models. Its versatile design allows it to be used across different engine configurations, providing a reliable solution for various applications.

The molded hose part 3970877 is crafted from high-quality materials, ensuring it can withstand the rigors of engine operation. Its compatibility with multiple engine models makes it a valuable component for maintenance and repair, offering a consistent and dependable performance across different engine types.

Role of Part 3970877 Molded Hose in Engine Systems

The part 3970877 molded hose is an integral component in the efficient operation of various engine systems, particularly in managing the breather and crankcase ventilation.

Breather System Integration

In the breather system, the molded hose facilitates the release of pressure that builds up inside the engine’s crankcase. This is essential for maintaining optimal engine performance and preventing damage from excessive pressure. The hose connects to the breather valve, allowing controlled venting of gases and moisture that accumulate during engine operation. This ensures that the engine operates within safe pressure limits, enhancing durability and reliability.

Crankcase Ventilation

The crankcase ventilation system relies on the molded hose to route gases away from the crankcase and back into the intake tract. This process helps in reducing emissions and improving fuel efficiency. The hose plays a key role in this system by providing a secure and leak-free connection between the crankcase and the intake manifold. This ensures that blow-by gases, which contain unburned fuel and combustion byproducts, are effectively managed and recirculated, rather than being released into the atmosphere.

Enhanced Engine Performance

By efficiently managing pressure and ventilation, the molded hose contributes to overall engine performance. It helps in maintaining a clean crankcase environment by preventing the buildup of sludge and contaminants, which can otherwise lead to engine wear and reduced efficiency. The reliable connection provided by the hose ensures that the breather and crankcase systems function seamlessly, supporting the engine’s longevity and operational stability.

Conclusion

The Cummins 3970877 Molded Hose is a critical component in the efficient operation of commercial truck engines. Its robust construction, compatibility with various engine models, and role in managing breather and crankcase ventilation systems make it an essential part for maintaining engine performance and reliability. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this Cummins part.

-

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Cummins Inc. (n.d.). Service Manual (5613155).

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.