This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

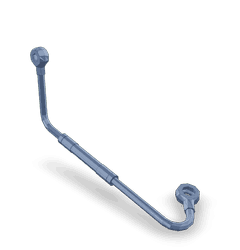

The Cummins 4963800 Flexible Hose is a component designed for use in commercial trucks. It serves a specific function within the truck’s systems, contributing to the efficient operation of various fluid or gas transfer processes. Understanding its purpose and significance is important for maintaining the overall performance and reliability of commercial vehicles.

Basic Concepts of Flexible Hoses

Flexible hoses are used in automotive systems to transfer fluids or gases between components. They are designed to accommodate movement and vibration, which are common in vehicle operations. Flexible hoses can be made from various materials, depending on the specific application and the type of fluid or gas they are intended to carry. Their ability to flex and bend without leaking makes them suitable for applications where rigid pipes would be impractical 1.

Purpose of the Cummins 4963800 Flexible Hose

The Cummins 4963800 Flexible Hose is designed to connect specific systems within a truck, facilitating the transfer of fluids or gases. It plays a role in ensuring that these systems operate efficiently by providing a reliable connection that can withstand the dynamic conditions present in commercial truck environments.

Key Features

The Cummins 4963800 Flexible Hose is characterized by several key features that enhance its performance. These include its material composition, which is selected to resist the specific fluids or gases it carries, as well as external conditions. The hose’s flexibility allows it to accommodate the movement and vibration inherent in truck operations, while its durability ensures long-term reliability. Design elements such as reinforced ends or specialized fittings may be included to further enhance its performance and longevity.

Benefits

Using the Cummins 4963800 Flexible Hose offers several advantages. It contributes to improved system reliability by providing a secure and leak-resistant connection. Its flexibility in routing allows for easier installation and maintenance, potentially reducing downtime. Over time, the durability and reliability of the hose can lead to cost savings by minimizing the need for frequent replacements or repairs.

Installation Considerations

Proper installation of the Cummins 4963800 Flexible Hose is important to ensure optimal performance and longevity. Installation procedures should follow manufacturer guidelines, which may include specific requirements for securing the hose, ensuring proper alignment, and checking for leaks after installation. Best practices may also involve inspecting the hose and its connections regularly to identify any signs of wear or damage 2.

Troubleshooting Common Issues

Common issues with flexible hoses, such as leaks, kinks, or degradation, can arise due to various factors including wear and tear, exposure to harsh conditions, or improper installation. Troubleshooting these issues involves identifying the source of the problem, which may require inspecting the hose for physical damage, checking connections for tightness, or assessing the condition of the fluid or gas being transferred. Solutions may include repairing or replacing the hose, adjusting connections, or addressing underlying system issues 3.

Maintenance Tips

Regular maintenance practices can help prolong the life of the Cummins 4963800 Flexible Hose. This includes inspecting the hose at recommended intervals for signs of wear, damage, or leaks. Cleaning procedures may be necessary to remove any buildup that could affect performance. Knowing when to consider replacement is also important, as continued use of a degraded hose could lead to system failures or leaks.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 4963800 Flexible Hose, which is designed to meet the demanding requirements of commercial truck applications.

ISM CM876 Engine and Flexible Hose 4963800

The ISM CM876 engine, a robust and reliable power unit, is designed to meet the demanding needs of various industrial applications. One of the critical components that ensure the smooth operation of this engine is the Flexible Hose 4963800, manufactured by Cummins. This hose is integral to the engine’s functionality, providing a flexible connection that accommodates movement and reduces stress on the engine’s components.

ISM CM876 Engine Group

The ISM CM876 engine is part of a series of engines that share common design principles and engineering excellence. The Flexible Hose 4963800 is specifically engineered to fit seamlessly within this engine group, ensuring compatibility and optimal performance across the range. This hose is designed to handle the unique demands of the ISM CM876 engine, providing a reliable connection that enhances the engine’s overall efficiency and durability.

Integration with ISM CM876

The Flexible Hose 4963800 is meticulously designed to integrate with the ISM CM876 engine, ensuring that it meets the stringent requirements of this high-performance engine. The hose’s flexibility allows it to adapt to the engine’s movements, reducing wear and tear on the connections and minimizing the risk of leaks or failures. This integration is crucial for maintaining the engine’s performance and longevity, as it ensures that the hose can withstand the pressures and temperatures typical of the ISM CM876 engine’s operation.

Compatibility and Performance

The Flexible Hose 4963800 is engineered to provide a perfect fit for the ISM CM876 engine, ensuring that it performs optimally under various conditions. This hose is designed to handle the specific requirements of the engine, providing a reliable and durable connection that enhances the engine’s overall performance. The compatibility of this hose with the ISM CM876 engine is a testament to Cummins’ commitment to quality and reliability, ensuring that the engine operates at its best at all times.

Role of Part 4963800 Flexible Hose in Plumbing and Turbocharger Systems

Plumbing Systems

In plumbing systems, the 4963800 Flexible Hose is utilized to connect various components, ensuring a secure and leak-free connection. It is commonly employed to link pipes, valves, and fixtures, accommodating the necessary flexibility to handle vibrations and movements that occur within the system. This flexibility is particularly important in areas where plumbing lines may experience thermal expansion or contraction, ensuring the system remains intact and functional over time. Additionally, the hose allows for easier installation and maintenance, as it can be routed around obstacles and adjusted as needed without the rigidity of traditional piping.

Turbocharger Systems

Within turbocharger systems, the 4963800 Flexible Hose plays a significant role in connecting the turbocharger to the engine’s intake and exhaust manifolds. This connection is vital for the efficient transfer of exhaust gases, which drive the turbine within the turbocharger. The flexibility of the hose is essential to manage the high temperatures and pressures associated with exhaust gases, as well as the vibrations generated by the engine. By providing a durable yet flexible link, the hose ensures that the turbocharger operates effectively, enhancing engine performance and efficiency. Furthermore, the hose’s design allows for easier access during maintenance, facilitating the replacement or inspection of the turbocharger without the need for complex disassembly.

Conclusion

The Cummins 4963800 Flexible Hose is a critical component in the efficient operation of commercial trucks, particularly in the ISM CM876 engine group. Its design, featuring flexibility, durability, and compatibility, ensures reliable performance in demanding environments. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the benefits of this part, contributing to the overall reliability and efficiency of commercial vehicles.

-

Reducing Particulate Emissions in Gasoline Engines, Thorsten Boger, Willard Cutler, SAE International, 2018

↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023

↩ -

Critical Component Wear in Heavy Duty Engines, P. A. Lakshminarayanan and Nagaraj S. Nayak, John Wiley & Sons, 2011

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.