This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

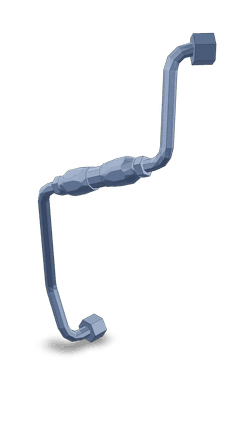

Understanding the Cummins 4944007 Flexible Hose

Introduction to Flexible Hoses

Flexible hoses are essential components in commercial truck engines, facilitating the transfer of fluids such as coolant, fuel, and hydraulic fluid. Unlike rigid pipes, flexible hoses can accommodate movement and vibration, which are common in dynamic engine environments. Their role is crucial in maintaining the integrity and efficiency of the engine system by ensuring consistent fluid flow and pressure 1.

Historical Context and Development

The evolution of flexible hoses in automotive engineering has been marked by significant innovations. Early hoses were prone to failure under the stress of engine vibrations and temperature fluctuations. The development of advanced materials and manufacturing techniques has led to more durable and reliable flexible hoses. Cummins has been at the forefront of this technological advancement, introducing products like the 4944007 flexible hose, which sets new standards in the industry 2.

Types of Flexible Hoses

Various types of flexible hoses are used in engines, each designed for specific applications. These include coolant hoses, fuel hoses, and hydraulic hoses, among others. The Cummins 4944007 stands out due to its unique features, such as reinforced layers and specialized materials that enhance its performance and durability.

Function and Importance of the Cummins 4944007 Flexible Hose

The Cummins 4944007 flexible hose plays a vital role in engine operation by ensuring the smooth and efficient transfer of fluids. It is designed to withstand high pressures and temperatures, maintaining optimal fluid flow which is essential for engine efficiency and longevity. A malfunctioning flexible hose can lead to severe engine issues, including overheating and reduced performance, underscoring the importance of this component 3.

Quality and Durability

The Cummins 4944007 is constructed from high-quality materials, including synthetic rubber and reinforced fabric layers, which provide exceptional resistance to wear and tear. The manufacturing process involves rigorous quality control measures to ensure each hose meets the highest standards of durability and performance. This hose is engineered to perform reliably under extreme conditions, making it suitable for the demanding environments of commercial trucks.

Indicators for Replacement

Regular inspections are crucial for identifying signs of wear and tear in flexible hoses. Common symptoms include cracks, leaks, and bulging, which indicate that a hose may need replacement. Preventive measures, such as avoiding sharp edges that could damage the hose and ensuring proper installation, can extend its lifespan. Early detection of issues through routine checks helps maintain engine performance and prevent costly repairs.

Maintenance Tips

Maintaining the Cummins 4944007 involves regular inspections and proper care. A step-by-step guide for inspection includes checking for visible damage, ensuring secure connections, and verifying that the hose is free from obstructions. Tools such as pressure testers and visual inspection kits are useful for thorough maintenance. Troubleshooting common issues, such as leaks or reduced flow, involves identifying the source of the problem and applying the appropriate repair or replacement measures.

Cummins’ Commitment to Quality

Cummins is dedicated to delivering high-quality products through stringent quality assurance processes. The company adheres to industry standards and certifications, ensuring that each component, including the 4944007 flexible hose, meets rigorous performance criteria. Cummins also provides extensive resources and support for engineers, mechanics, and fleet operators, offering guidance on maintenance, troubleshooting, and optimal use of their products. This commitment to quality and support underscores Cummins’ reputation in the commercial truck industry.

Flexible Hose 4944007 Compatibility with Cummins Engines

The Cummins Flexible Hose part number 4944007 is a crucial component designed to ensure seamless fluid transfer in various applications. This part is engineered to fit perfectly with the following Cummins engines:

QSB5.9 CM850

The QSB5.9 CM850 engine, known for its robust performance and reliability, benefits significantly from the 4944007 Flexible Hose. This hose is designed to withstand the high pressures and temperatures typical of this engine, ensuring efficient and uninterrupted fluid flow. Its flexibility allows it to adapt to the engine’s movements, reducing wear and tear on the connections and enhancing overall durability.

QSB6.7 M CM2250

Similarly, the QSB6.7 M CM2250 engine, which is renowned for its power and efficiency, is another ideal candidate for the 4944007 Flexible Hose. This hose is engineered to handle the demanding conditions of the QSB6.7 M CM2250, providing a reliable connection that minimizes leaks and maintains optimal performance. Its design ensures that the hose can endure the rigors of continuous operation, contributing to the engine’s longevity and efficiency.

By integrating the 4944007 Flexible Hose into these engines, users can expect enhanced operational efficiency, reduced maintenance needs, and improved overall performance. This part is a testament to Cummins’ commitment to providing high-quality, durable components that meet the exacting standards of their engines.

Role of Part 4944007 Flexible Hose in Engine Systems

In the context of engine systems, the 4944007 Flexible Hose serves as a vital connector, facilitating the smooth transfer of fluids between various components. Specifically, it is integral to the operation of the full flow oil filter system.

Connection to Full Flow Oil Filter

The 4944007 Flexible Hose is designed to link the oil pump to the full flow oil filter. This connection ensures that oil is efficiently circulated from the pump to the filter, where contaminants are removed before the oil is distributed throughout the engine. The flexibility of the hose accommodates the necessary movements and vibrations within the engine compartment, maintaining a secure and leak-free connection.

Enhancing System Reliability

By providing a durable and flexible linkage, the 4944007 Hose contributes to the overall reliability of the oil filtration system. Its design allows for consistent oil flow, which is essential for maintaining proper lubrication of engine components. This, in turn, helps in reducing wear and tear, ensuring the engine operates smoothly and efficiently.

Integration with Other Components

Beyond its primary role in the oil filtration process, the 4944007 Hose may also interface with other engine components such as the oil cooler or bypass valve, depending on the specific engine configuration. Its versatile design makes it suitable for various applications within the engine system, enhancing its utility and effectiveness.

In summary, the 4944007 Flexible Hose plays a significant role in maintaining the integrity and efficiency of the engine’s oil circulation and filtration system, ensuring optimal performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.