This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3047360 Flexible Hose is a component designed for use in commercial trucks. Its primary function is to facilitate the transfer of fluids or gases between different parts of the vehicle’s systems. This hose is significant in the overall operation of the truck, ensuring that systems remain connected and operational under various conditions 1.

Basic Concepts of Flexible Hoses

Flexible hoses are tubes made from materials that allow them to bend and flex without breaking. They are commonly used in automotive systems to connect components that may move relative to each other. Unlike rigid hoses, flexible hoses can accommodate movement and vibration, reducing the risk of damage. Materials used in manufacturing flexible hoses typically include rubber, thermoplastic, and metal reinforcements. These materials are chosen for their durability, flexibility, and resistance to the fluids or gases they transport 2.

Purpose of the 3047360 Flexible Hose

The Cummins 3047360 Flexible Hose plays a specific role in the operation of a truck by connecting various systems and transporting fluids or gases. It is designed to link components that experience movement or vibration during operation, ensuring a continuous and secure flow between them.

Key Features

The Cummins 3047360 Flexible Hose features a design that includes multiple layers of materials to enhance its performance and durability. The construction typically involves an inner layer that contacts the fluid or gas, a reinforcement layer for strength, and an outer layer for protection. These layers work together to provide flexibility, resistance to pressure, and longevity.

Benefits

Using the Cummins 3047360 Flexible Hose in truck applications offers several advantages. Its flexibility allows it to accommodate movement and vibration, reducing the likelihood of damage. The hose is designed to resist wear and tear, ensuring long-lasting performance. Additionally, its ease of installation makes it a practical choice for maintenance and repair tasks 3.

Installation Considerations

When installing the Cummins 3047360 Flexible Hose, it is important to follow guidelines and best practices to ensure proper function. This includes aligning the hose correctly, securing it in place with appropriate methods, and verifying compatibility with the existing systems in the truck. Proper installation helps maintain the integrity of the hose and the systems it connects.

Troubleshooting Common Issues

Common problems associated with flexible hoses include leaks, kinks, and degradation over time. To address these issues, it is important to conduct regular inspections and perform step-by-step troubleshooting. Identifying the source of a leak, unkinking a hose, and replacing a degraded section are all part of maintaining the hose’s performance.

Maintenance Tips

To ensure the longevity and reliable performance of the Cummins 3047360 Flexible Hose, regular maintenance practices are recommended. This includes inspecting the hose at intervals, cleaning it as needed, and considering replacement when signs of wear or damage are present. Adhering to these practices helps maintain the hose’s condition and the overall efficiency of the truck’s systems.

Safety Considerations

When working with flexible hoses, it is important to observe safety protocols. This includes proper handling to avoid damage, storing the hose in a suitable environment, and disposing of it according to regulations. Using genuine parts for replacements is also crucial to ensure compatibility and safety.

About Cummins

Cummins Inc. is a company with a history of providing quality products in the automotive industry. Its range of products includes engines, filtration systems, and components like the 3047360 Flexible Hose. Cummins is committed to innovation and excellence, ensuring that its parts meet the demands of commercial applications.

Cummins Part 3047360: Flexible Hose Compatibility with K19 Engines

The Cummins part 3047360, a Flexible Hose, is designed to integrate seamlessly with various engine models, including the K19 series. This part is crucial for maintaining the integrity of fluid systems within these engines, ensuring that connections remain flexible and durable under operational stresses.

Integration with K19 Engines

The K19 engine series, known for its robust performance, relies on precise fluid management to maintain optimal operation. The Flexible Hose part 3047360 is engineered to fit these engines by providing a reliable connection between different components, such as the fuel lines, coolant lines, and other fluid pathways. Its flexibility allows for movement and reduces the risk of wear and tear that can occur with rigid connections.

Compatibility Considerations

When installing the Flexible Hose part 3047360 in K19 engines, it is essential to ensure that the hose is correctly aligned with the engine’s design specifications. This includes matching the hose’s diameter, length, and connection points to prevent leaks and maintain system efficiency. Cummins has designed this part to be compatible with the K19 series, ensuring that it meets the stringent requirements of these high-performance engines.

Installation and Maintenance

Proper installation of the Flexible Hose part 3047360 is critical to its performance. Technicians should follow Cummins’ guidelines for securing the hose to prevent disconnections during operation. Regular maintenance checks are also recommended to inspect for signs of wear, cracks, or leaks, ensuring the hose continues to function as intended.

Grouping with Other Cummins Engines

While the Flexible Hose part 3047360 is specifically designed for the K19 series, it can also be compatible with other Cummins engine models that share similar design parameters. Technicians should verify compatibility with specific engine models to ensure the hose fits correctly and performs optimally.

Role of Part 3047360 Flexible Hose in Engine Systems

The 3047360 Flexible Hose is an essential component in the efficient operation of various engine systems. It facilitates the seamless transfer of fluids between different parts, ensuring optimal performance and longevity of the engine.

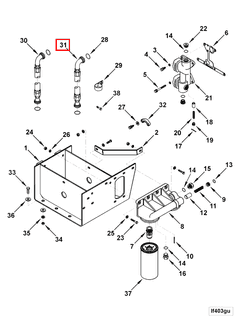

Lubricating Oil System

In the lubricating oil system, the 3047360 Flexible Hose connects the lubricating oil filter to the engine block. This connection allows for the smooth flow of oil from the filter back into the engine, ensuring that all moving parts receive adequate lubrication. This reduces friction and wear, contributing to the engine’s overall efficiency and durability.

Lubricating Filter Plumbing

The hose plays a significant role in the lubricating filter plumbing by linking the lubricating oil filter to other components within the system. This ensures that the oil is properly circulated through the filter, removing contaminants and maintaining the oil’s quality. Effective filtration is vital for preventing damage to the engine’s internal components.

Lubricating Oil Filter Head Kit

When integrated with the lubricating oil filter head kit, the 3047360 Flexible Hose enables the secure attachment of the filter head to the engine. This setup ensures that the oil filter is correctly positioned and sealed, preventing leaks and maintaining the integrity of the lubrication system. The hose’s flexibility accommodates the various movements and vibrations within the engine compartment, ensuring a reliable connection.

Oil Filter

The hose also connects the oil filter to the engine, allowing for the efficient filtration of lubricating oil. This connection is essential for maintaining clean oil, which is crucial for the engine’s performance and longevity. The flexible nature of the hose ensures that it can withstand the dynamic environment of the engine compartment without compromising the flow of oil.

Conclusion

In summary, the 3047360 Flexible Hose is a versatile component that enhances the functionality of several engine systems by ensuring the smooth and reliable transfer of lubricating oil. Its role in connecting critical components like the oil filter, filter head kit, and plumbing systems underscores its importance in maintaining engine health and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.