This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

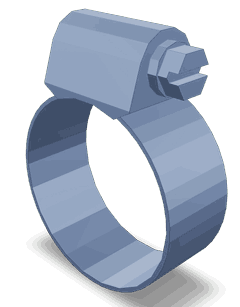

The Hose Clamp 5369779, manufactured by Cummins, is a specialized component designed for use in commercial truck operations. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this hose clamp to meet the rigorous demands of commercial vehicles. This clamp plays a significant role in ensuring the secure connection of hoses within various truck systems, contributing to the overall efficiency and reliability of truck operations.

Basic Concepts of Hose Clamps

Hose clamps are mechanical fasteners used to secure hoses to fittings. Their primary function is to create a tight seal, preventing leaks and ensuring the proper flow of fluids or gases through the hose. There are several types of hose clamps available, including worm-drive, spring, and screw-type clamps, each designed for specific applications and environments. The choice of clamp depends on factors such as the type of hose, the pressure of the fluid or gas, and the environmental conditions in which the hose will operate 1.

Purpose of Hose Clamp 5369779 in Truck Operations

The Hose Clamp 5369779 is specifically designed for use in commercial trucks, where it serves multiple functions across various systems. It is commonly applied in fuel, coolant, and pneumatic systems to secure hoses and ensure a reliable connection. By maintaining a tight seal, this clamp helps prevent leaks, which can lead to system failures or inefficiencies. Its application in these critical systems underscores its importance in maintaining the operational integrity of commercial trucks.

Key Features of Hose Clamp 5369779

The Hose Clamp 5369779 is characterized by its robust design and high-quality materials. It features a durable band material, typically made from stainless steel or a similar corrosion-resistant alloy, ensuring longevity and reliability in harsh operating conditions. The clamp also incorporates a screw mechanism that allows for precise adjustment, enabling a secure fit on a variety of hose sizes. This design ensures that the clamp can accommodate different applications within the truck’s systems.

Benefits of Using Hose Clamp 5369779

Utilizing the Hose Clamp 5369779 offers several advantages. Its design facilitates ease of installation, allowing for quick and efficient securing of hoses. The durability of the materials used ensures that the clamp can withstand the rigors of commercial truck operations, providing a reliable seal over time. Additionally, the precise adjustment capability of the screw mechanism ensures a secure fit, minimizing the risk of leaks and enhancing the overall performance of the truck’s systems.

Installation and Usage Guidelines

Proper installation of the Hose Clamp 5369779 is crucial for ensuring its effectiveness. To install, first, ensure the hose is clean and free of any debris. Position the clamp around the hose and fitting, then use the screw mechanism to tighten the clamp until a secure fit is achieved. It is important to follow torque specifications provided by the manufacturer to avoid over-tightening, which can damage the hose, or under-tightening, which can lead to leaks. Regular checks should be performed to ensure the clamp remains securely fastened.

Troubleshooting Common Issues

Common issues with hose clamps include leaks and improper sealing. If a leak is detected, the first step is to ensure the clamp is properly tightened. If the problem persists, inspect the hose and fitting for damage or debris that may be preventing a secure seal. In some cases, replacing the clamp or the hose may be necessary to resolve the issue. Regular maintenance and inspection can help identify and address these problems before they lead to more significant issues.

Maintenance Tips

To ensure the continued performance and longevity of the Hose Clamp 5369779, regular inspection and maintenance are recommended. Check the clamp for signs of corrosion or wear, and ensure it remains securely fastened. Clean the clamp and surrounding areas to remove any debris that could affect its performance. Following these maintenance practices will help maintain the integrity of the truck’s systems and ensure reliable operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial vehicle industry. The company’s extensive product range and commitment to customer satisfaction make it a trusted partner for commercial truck operators worldwide.

Cummins Hose Clamp 5369779 Compatibility with Engine Models

The Cummins Hose Clamp part number 5369779 is designed to fit seamlessly with several engine models, ensuring a secure and reliable connection for various hoses within the engine system. This part is crucial for maintaining the integrity of the engine’s cooling, fuel, and exhaust systems by preventing leaks and ensuring that hoses remain firmly attached to their respective fittings.

L8.9 CM2670 L134C

The L8.9 CM2670 L134C engine benefits from the use of the Cummins Hose Clamp 5369779. This part is engineered to fit the specific design and requirements of the L8.9 engine, ensuring that all hose connections are tight and secure. The clamp’s robust construction and precise fit are essential for maintaining the engine’s performance and longevity.

QSL9.3 CM2880 L113

Similarly, the QSL9.3 CM2880 L113 engine also utilizes the Cummins Hose Clamp 5369779. This part is compatible with the unique design of the QSL9.3 engine, providing a reliable solution for securing hoses in high-stress environments. The clamp’s durability and precision make it an ideal choice for ensuring that hoses remain connected without failure, thereby supporting the engine’s overall efficiency and reliability.

By using the Cummins Hose Clamp 5369779, both the L8.9 CM2670 L134C and QSL9.3 CM2880 L113 engines can maintain optimal performance and reliability, thanks to the secure and leak-proof connections provided by this essential component.

Role of Part 5369779 Hose Clamp in Engine Systems

In the context of engine systems, the part 5369779 Hose Clamp is instrumental in ensuring the secure and efficient operation of various components. Specifically, it plays a significant role in the compressor coolant arrangement and the compressor water inlet tube.

Compressor Coolant Arrangement

The compressor coolant arrangement is a vital subsystem within the engine, designed to regulate the temperature of the compressor. This is achieved through a network of hoses and tubes that circulate coolant to dissipate heat effectively. The part 5369779 Hose Clamp is employed to maintain a tight seal around these hoses, preventing any coolant leaks that could compromise the cooling efficiency. By ensuring a consistent flow of coolant, the clamp contributes to the stable operation of the compressor, thereby enhancing the overall performance and longevity of the engine.

Compressor Water Inlet Tube

The compressor water inlet tube is another component where the part 5369779 Hose Clamp demonstrates its utility. This tube is responsible for directing water into the compressor, which is essential for cooling and lubricating the internal components. The hose clamp secures the connection between the tube and the compressor, ensuring that water flows smoothly without any interruptions. This seamless flow is critical for maintaining the optimal temperature within the compressor, thus preventing overheating and potential damage.

Conclusion

In summary, the part 5369779 Hose Clamp is an essential element in the compressor coolant arrangement and the compressor water inlet tube, facilitating efficient heat management and ensuring the reliable operation of these components within the engine system. Its robust design, precise fit, and compatibility with various engine models make it a critical component for maintaining the performance and reliability of commercial trucks.

-

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.