This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

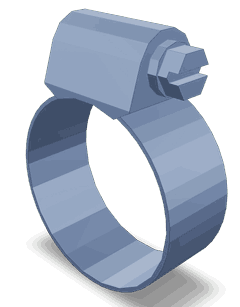

The Hose Fastening Clamp 4939547, manufactured by Cummins, is a component designed to secure hoses in commercial truck operations. Cummins, a well-established name in the commercial truck industry, produces this clamp to ensure reliable and efficient hose connections in various truck systems. The clamp’s role is significant in maintaining the integrity and functionality of hose-based systems within trucks 1.

Basic Concepts

A Hose Fastening Clamp is a device used to secure hoses in place, preventing leaks and ensuring that the hose remains connected under operational conditions. It operates by applying consistent pressure around the hose, creating a tight seal that withstands vibrations and movements typical in truck operations 2. This consistent pressure is crucial for maintaining the efficiency and safety of fluid transfer systems within the truck.

Purpose of the Hose Fastening Clamp 4939547

The Hose Fastening Clamp 4939547 is specifically designed to play a role in securing hoses within a truck’s system. Its application spans across various truck systems, including fuel, coolant, and hydraulic lines. By ensuring a secure connection, it helps maintain the efficiency of these systems, preventing leaks that could lead to system failures or inefficiencies 3.

Key Features

The Hose Fastening Clamp 4939547 is constructed from durable materials, ensuring longevity and reliability in demanding truck environments. Its design includes elements that allow for easy installation and adjustment, facilitating quick and secure hose connections. Additionally, the clamp features a unique band design that provides a uniform clamping force around the hose, enhancing its sealing capabilities.

Benefits

Utilizing the Hose Fastening Clamp 4939547 offers several advantages. It provides improved hose security, reducing the risk of disconnections and leaks. The ease of installation allows for quick setup and adjustment, minimizing downtime during maintenance or repairs. Its durable construction ensures long-term reliability, even under harsh operating conditions. Furthermore, the clamp’s design contributes to efficient fluid transfer, supporting the overall performance of the truck’s systems.

Installation Process

Installing the Hose Fastening Clamp 4939547 involves several steps to ensure effective clamping. Begin by positioning the clamp around the hose at the connection point. Use the provided tool to tighten the clamp gradually, ensuring even pressure distribution. It’s important to follow the manufacturer’s guidelines for torque settings to avoid over-tightening, which could damage the hose or the clamp itself. Regular checks post-installation are recommended to confirm the clamp remains secure.

Troubleshooting and Maintenance

Common issues with Hose Fastening Clamps may include leaks due to improper installation or wear and tear over time. Troubleshooting involves checking the clamp for proper tightness and inspecting the hose for damage. Maintenance tips include regular inspection of the clamp and hose for signs of wear, ensuring the clamp remains securely fastened, and replacing the clamp if it shows signs of significant wear or damage.

Safety Considerations

When installing or maintaining the Hose Fastening Clamp 4939547, it’s important to observe safety guidelines to protect personnel and ensure the integrity of the truck’s systems. This includes wearing appropriate personal protective equipment (PPE), ensuring the truck is turned off and cooled down before beginning work, and following the manufacturer’s instructions for installation and maintenance. Additionally, be mindful of the pressure within the hose system to avoid injuries from sudden releases.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Compatibility with Cummins Engines

The Hose Fastening Clamp 4939547, manufactured by Cummins, is designed to securely fasten hoses to various engine parts, preventing leaks and maintaining the efficiency of the engine’s systems.

ISB (Chrysler)

The ISB engine, developed by Chrysler, incorporates the Hose Fastening Clamp 4939547 in its design to ensure reliable hose connections. This clamp is essential for maintaining the pressure and flow of fluids within the engine, contributing to the overall performance and longevity of the ISB engine.

ISB CM850

The ISB CM850 engine also utilizes the Hose Fastening Clamp 4939547. This engine variant, known for its robust performance and reliability, depends on the clamp to secure hoses effectively. The clamp’s design ensures that hoses remain firmly attached, even under the demanding conditions of engine operation, thereby preventing potential leaks and maintaining system integrity.

Role in Various Engine Systems

The Hose Fastening Clamp 4939547 is an essential component in ensuring the secure attachment of hoses within various engine systems. Its application spans across different types of hoses and systems, contributing to the overall efficiency and safety of the engine operation.

Plain Hose Applications

In systems utilizing plain hoses, the 4939547 clamp plays a significant role in maintaining a leak-free connection. This is particularly important in fuel delivery systems where any leakage can pose a significant safety hazard. The clamp ensures that the hose remains firmly attached to the fitting, preventing any potential fuel leaks that could lead to dangerous situations.

Plumbing Systems

Within the context of vehicle plumbing systems, the 4939547 clamp is used to secure hoses that carry coolant or other fluids. This is vital for maintaining the integrity of the cooling system, ensuring that the engine operates within the optimal temperature range. A secure connection prevents coolant loss, which could lead to engine overheating and potential damage.

Cabin Heater Systems

The clamp is also integral in cabin heater systems, where it secures the hoses that transport hot coolant from the engine to the heater core. This ensures that the cabin heating system functions efficiently, providing comfortable temperatures inside the vehicle. A secure connection is essential to prevent coolant leaks, which could impair the heating system’s performance and lead to discomfort for passengers.

Vehicle Heater Tube Applications

In applications involving vehicle heater tubes, the 4939547 clamp ensures that the tubes remain securely attached to the fittings. This is important for the efficient transfer of heat from the engine to the vehicle’s interior. A secure connection prevents any loss of heat transfer efficiency, ensuring that the vehicle’s heating system operates effectively.

Conclusion

The Hose Fastening Clamp 4939547 by Cummins is a versatile and essential component that enhances the reliability and safety of various engine systems by ensuring secure hose connections. Its compatibility with Cummins engines, including the ISB and ISB CM850, underscores its importance in maintaining the efficiency and reliability of these engines. The clamp’s role in securing hoses across different systems, from fuel delivery to cabin heating, highlights its critical contribution to the overall performance and safety of commercial trucks.

-

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩ -

Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body, David C Barton and John D Fieldhouse, Elsevier, 2009

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.