This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

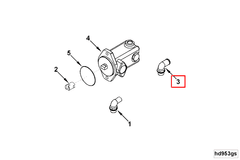

The Elbow Hose Coupling part #4938302 is a component manufactured by Cummins, designed for use in commercial truck systems. This part contributes to the efficient operation of trucks by ensuring the proper flow and management of fluids within the system. Its role is significant in maintaining the overall performance and reliability of truck operations.

Basic Concepts of Elbow Hose Couplings

Elbow hose couplings are fittings used to connect hoses at an angle, facilitating the transfer of fluids such as coolant and hydraulic fluid within a truck’s system. These couplings are integral to the fluid systems, allowing for flexible and efficient routing of hoses around obstacles and tight spaces. They ensure that fluid flow is maintained without leakage, contributing to the system’s overall integrity and performance 1.

Purpose of the 4938302 Elbow Hose Coupling

The 4938302 Elbow Hose Coupling is specifically designed to direct fluid flow within a truck’s system, ensuring that fluids are efficiently routed to their intended destinations. This part helps maintain system integrity by providing a secure and reliable connection between hoses, which is vital for the consistent operation of the truck’s fluid systems.

Key Features

The 4938302 Elbow Hose Coupling boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. The coupling features robust connection types that provide a secure fit, minimizing the risk of disconnection. Its design includes elements that facilitate easy installation and maintenance, contributing to its overall effectiveness.

Benefits

Utilizing the 4938302 Elbow Hose Coupling offers several benefits. It contributes to improved fluid system efficiency by ensuring a smooth and uninterrupted flow of fluids. The coupling’s design reduces the risk of leakage, enhancing system reliability. Additionally, its durable construction ensures it can withstand the demanding conditions typical of commercial truck operations, providing long-term value 2.

Installation Considerations

When installing the 4938302 Elbow Hose Coupling, it is important to follow guidelines and best practices to ensure optimal performance. Proper alignment of the coupling is crucial to avoid stress on the hoses and connections. Adherence to torque specifications during installation helps secure the coupling without over-tightening, which could damage the fitting. Post-installation system testing is recommended to verify the integrity of the connections and the efficiency of fluid flow 3.

Troubleshooting Common Issues

Common issues associated with elbow hose couplings include leaks and connection failures. To troubleshoot these problems, it is important to inspect the coupling and hoses for signs of wear or damage. Ensuring that connections are properly torqued and aligned can prevent many issues. Regular maintenance and inspection routines can help identify potential problems before they lead to system failures.

Maintenance Tips

Regular maintenance of the 4938302 Elbow Hose Coupling is key to ensuring its continued performance and durability. Inspection routines should include checking for signs of wear, corrosion, or damage. Cleaning the coupling and surrounding areas can prevent the buildup of debris that might affect performance. When signs of significant wear or damage are observed, considering replacement of the coupling is advisable to maintain system integrity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins plays a significant role in the commercial truck industry. The company’s focus on developing reliable and efficient components underscores its dedication to enhancing the performance and reliability of commercial vehicles.

Compatibility of Elbow Hose Coupling Part 4938302 with Cummins Engines

The Elbow Hose Coupling part 4938302, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for ensuring proper fluid flow and maintaining the integrity of the engine’s cooling and exhaust systems.

Cummins Engines Compatible with Part 4938302

- 6B5.9

- B5.9 GAS PLUS CM556

- ISB/ISD6.7 CM2150 SN

- ISBE CM2150

- ISBE4 CM850

Grouping of Compatible Engines

The engines listed can be grouped based on their series and specifications. The ISB/ISD6.7 CM2150 SN and ISBE CM2150 belong to the same series, indicating similar design and functionality. Similarly, the ISBE4 CM850 shares some common features with the ISBE CM2150, making the part 4938302 compatible across these models.

The 6B5.9 and B5.9 GAS PLUS CM556 engines, while distinct in their specifications, also accommodate the part 4938302 due to their shared design principles in fluid management systems.

This compatibility ensures that the Elbow Hose Coupling part 4938302 can be used across multiple engine models, providing a reliable solution for maintaining the engine’s operational efficiency.

Role of Part 4938302 Elbow Hose Coupling in Engine Systems

The 4938302 Elbow Hose Coupling is an essential component in the fluid dynamics of engine systems, particularly when interfacing with the pump and auxiliary systems.

Integration with the Pump

When integrated with the pump, the Elbow Hose Coupling ensures a secure and leak-free connection between the pump outlet and the subsequent hose or pipe. This coupling allows for a change in direction of the fluid flow, which is often necessary to navigate the compact and intricate layout of engine compartments. The secure fit provided by the coupling prevents any potential fluid loss, maintaining the efficiency and reliability of the pump’s operation.

Connection to Auxiliary Systems

In auxiliary systems, the 4938302 Elbow Hose Coupling plays a similarly important role. These systems may include cooling circuits, lubrication lines, or hydraulic systems that require precise fluid management. The coupling’s ability to facilitate a directional change in the hose layout is particularly beneficial in these applications, allowing for more flexible and efficient routing of hoses. This not only optimizes the space utilization within the engine bay but also reduces the risk of hose abrasion or damage, which can lead to system failures.

Overall Functionality

Overall, the 4938302 Elbow Hose Coupling enhances the operational integrity of both the primary pump and various auxiliary systems by providing a robust and adaptable connection point. Its design accommodates the dynamic requirements of engine systems, ensuring that fluid transfer remains uninterrupted and efficient.

Conclusion

The 4938302 Elbow Hose Coupling by Cummins is a vital component in the efficient operation of commercial truck systems. Its design and features contribute to the reliable management of fluid flow, ensuring the performance and reliability of truck operations. Proper installation, maintenance, and understanding of its role within engine systems are crucial for maximizing its benefits.

-

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.