This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

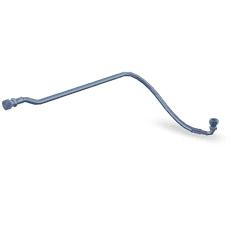

The Water Outlet Tube for Compressor, identified by Cummins Part #4910106, is a component integral to the cooling systems of heavy-duty trucks. Manufactured by Cummins, a reputable name in the automotive industry, this part ensures efficient operation of the compressor by managing water flow. Its role in maintaining the overall performance and longevity of the truck’s engine is significant 1.

Function and Operation

The Water Outlet Tube for Compressor operates by directing the flow of water from the compressor to other parts of the cooling system. This controlled water flow helps in dissipating heat generated by the compressor, thereby maintaining optimal operating temperatures. The tube’s design allows for efficient water circulation, which is vital for the compressor’s performance and durability 2.

Purpose of the Water Outlet Tube for Compressor

In the operation of a heavy-duty truck, this Cummins part plays a specific role in the cooling system. It contributes to the efficient removal of excess heat from the compressor, which is essential for maintaining engine performance. By ensuring that the compressor operates within the desired temperature range, this component helps in preserving the overall efficiency and reliability of the truck 3.

Key Features

The Water Outlet Tube for Compressor is characterized by several key features that enhance its functionality. It is typically made from durable materials that can withstand high temperatures and pressures. The design of the tube includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature reinforced sections to handle the rigors of heavy-duty use 4.

Benefits

The advantages of using the Water Outlet Tube for Compressor include improved compressor longevity, enhanced cooling efficiency, and potential cost savings for fleet operators. By maintaining optimal compressor temperatures, the tube helps in reducing the risk of overheating and related damage. This, in turn, can lead to lower maintenance costs and increased uptime for the vehicle 1.

Installation Considerations

Proper installation of the Water Outlet Tube for Compressor is vital for ensuring optimal performance. Before installation, it is important to verify that all prerequisites are met, such as ensuring the compressor and cooling system are clean and free of debris. The necessary tools for installation may include wrenches, sealant, and possibly a torque wrench to ensure proper tightening of connections. Following the manufacturer’s guidelines for installation will help in achieving the best results 2.

Common Issues and Troubleshooting

Typical problems associated with the Water Outlet Tube for Compressor may include leaks, blockages, or damage to the tube itself. Troubleshooting these issues involves inspecting the tube for signs of wear or corrosion, checking connections for tightness, and ensuring that there are no obstructions in the water flow path. Regular maintenance and prompt repairs can help in addressing these issues effectively 3.

Maintenance Tips

To prolong the lifespan of the Water Outlet Tube for Compressor, routine maintenance practices are recommended. This includes regular inspection intervals to check for any signs of wear or damage. Cleaning the tube and its connections can prevent buildup that may impede water flow. Additionally, following the manufacturer’s replacement guidelines can ensure that the component remains in optimal condition 4.

Cummins Overview

Cummins is a well-established manufacturer in the automotive industry, known for its high-quality components and innovative solutions. With a history of delivering reliable products, Cummins has built a strong reputation for excellence. The company’s commitment to manufacturing top-tier automotive components is evident in their extensive range of parts, including the Water Outlet Tube for Compressor.

Compatibility with Cummins Engines

The Water Outlet Tube for Compressor, identified by the part number 4910106, is a critical component in the cooling system of various Cummins engines. This part is designed to facilitate the flow of coolant from the compressor to the radiator, ensuring efficient heat dissipation and maintaining optimal engine temperature.

K19 Series Engines

The K19 series engines, including the K19 and KTA19GC, are robust and reliable power units often used in industrial and marine applications. The Water Outlet Tube for Compressor fits seamlessly into these engines, providing a secure connection between the compressor and the coolant system. This ensures that the coolant is effectively circulated, preventing overheating and maintaining engine performance.

KTA19GC CM558 Engines

The KTA19GC CM558 engine is a variant of the KTA19GC series, designed with specific enhancements for certain applications. The Water Outlet Tube for Compressor is engineered to fit this engine model, ensuring compatibility and efficient coolant flow. This part is crucial for maintaining the engine’s thermal balance and preventing potential damage from overheating.

V903 and VTA903 Series Engines

The V903 and VTA903 series engines, including the VTA903 CM2250 V105, are high-performance engines used in various heavy-duty applications. The Water Outlet Tube for Compressor is designed to integrate with these engines, providing a reliable pathway for coolant to exit the compressor and enter the radiator. This ensures that the engine operates within its optimal temperature range, enhancing durability and performance.

Role of Part 4910106 Water Outlet Tube for Compressor in Engine Systems

The Water Outlet Tube for Compressor (part 4910106) is an essential component in the efficient operation of several engine systems, particularly in turbocharged setups. Its primary function is to facilitate the flow of coolant from the compressor to other critical areas of the engine, ensuring optimal thermal management.

Integration with Aftercooler

In systems equipped with an aftercooler, the Water Outlet Tube plays a significant role. After the compressed air exits the turbocharger, it is often routed through the aftercooler to reduce its temperature before entering the intake manifold. The coolant circulating through the Water Outlet Tube helps in dissipating the heat absorbed by the aftercooler, thereby enhancing the efficiency of the air-cooling process.

Turbocharger and Turbocharger Mounting

The turbocharger, a device that compresses the intake air to increase engine power, generates a substantial amount of heat. The Water Outlet Tube is integral in channeling coolant to the turbocharger housing, which aids in maintaining the turbocharger’s operational temperature. Proper turbocharger mounting and the use of appropriate turbocharger mounting hardware ensure that the Water Outlet Tube is securely positioned, allowing for efficient coolant flow without leaks.

Manifold and Exhaust Systems

The intake manifold, where the cooled and pressurized air is distributed to the engine cylinders, benefits from the regulated temperature provided by the Water Outlet Tube. Similarly, in some advanced engine designs, the exhaust system may incorporate water injection to reduce temperatures and improve efficiency. The Water Outlet Tube ensures a consistent supply of coolant to these areas, contributing to the overall performance and longevity of the engine components.

Plumbing and System Arrangement

Effective plumbing is vital for the Water Outlet Tube’s function within the engine system. The arrangement of pipes and hoses must be meticulously planned to ensure that coolant reaches all necessary points without restriction. This includes connections to the turbocharger, aftercooler, and potentially the exhaust system, depending on the engine’s design.

Conclusion

In summary, the Water Outlet Tube for Compressor (part 4910106) is a key element in the thermal management of turbocharged engine systems, working in conjunction with the aftercooler, turbocharger, manifold, and exhaust to maintain optimal operating temperatures and enhance engine performance.

-

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ ↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ ↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ ↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.