This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

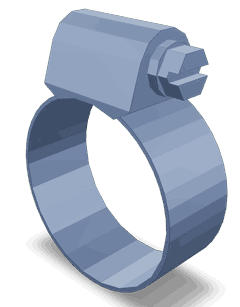

The Hose Clamp 4901130 by Cummins is a specialized component designed for use in commercial trucks. Its purpose is to secure hoses within various systems, ensuring they remain firmly in place and function correctly. This clamp is significant in maintaining the integrity and efficiency of truck operations, particularly in systems where hoses are subject to vibration, pressure, and environmental factors.

Basic Concepts of Hose Clamps

Hose clamps are mechanical devices used to secure hoses to fittings, ensuring a tight seal and preventing leaks. They come in various types, including worm-drive, spring, and screw-type clamps, each suited to different applications based on the specific requirements of the system they serve. Hose clamps play a vital role in maintaining the functionality and safety of fluid transfer systems in vehicles 1.

Purpose of Hose Clamp 4901130

The Hose Clamp 4901130 is designed to secure hoses in critical systems within commercial trucks, such as fuel, coolant, and pneumatic systems. It ensures that hoses remain connected under various operating conditions, contributing to the overall reliability and performance of the truck. By maintaining a secure connection, it helps prevent leaks and ensures that fluids and gases are transferred efficiently throughout the system.

Key Features

The Hose Clamp 4901130 features a durable construction, typically made from high-quality materials that resist corrosion and wear. Its design includes elements that enhance performance, such as a robust band that provides a strong grip on the hose and a mechanism for easy adjustment. These features ensure that the clamp can withstand the demanding conditions found in commercial truck applications.

Benefits

Using the Hose Clamp 4901130 offers several benefits, including improved reliability in hose connections, which is crucial for the safe and efficient operation of truck systems. Its design allows for ease of installation, reducing downtime during maintenance procedures. Additionally, the clamp’s durability and resistance to environmental factors contribute to lower maintenance requirements over time.

Installation Process

Proper installation of the Hose Clamp 4901130 involves several steps to ensure a secure fit. First, the hose should be properly aligned with the fitting. Then, the clamp is positioned around the hose and fitting, ensuring it covers the entire connection. Using the appropriate tools, the clamp is tightened until it achieves the recommended torque, ensuring a leak-proof seal without damaging the hose.

Troubleshooting Common Issues

Common issues with hose clamps include leaks due to improper sealing or clamp failure. To address these problems, it is important to inspect the clamp and hose for signs of wear or damage. Ensuring the clamp is correctly installed and tightened to the manufacturer’s specifications can prevent many issues. Regular maintenance and inspection can help identify potential problems before they lead to system failures.

Maintenance Tips

Regular maintenance of hose clamps is key to ensuring their longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the clamp and hose connection points can prevent buildup that may affect performance. Replacing worn or damaged clamps promptly ensures the continued reliability of the system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and stationary applications, as well as related technologies that increase fuel efficiency and reduce emissions 2.

Compatibility with Engine Models

The Hose Clamp 4901130 is designed to fit seamlessly with a range of Cummins engine models. This part is engineered to ensure a secure and leak-proof connection for various hoses within the engine system. Below is a detailed description of its compatibility with specific engine models:

A1400 and A1700 Engines

The Hose Clamp 4901130 is compatible with both the A1400 and A1700 engines. These engines, while differing in size and power output, share similar design elements that allow for the effective use of this hose clamp. The clamp’s robust construction ensures it can withstand the operational stresses of these engines, providing a reliable seal that is crucial for maintaining system integrity.

A2000 and A2300 Engines

Similarly, the A2000 and A2300 engines are designed to integrate the Hose Clamp 4901130 without any issues. These engines, being more powerful and larger in size, benefit from the clamp’s ability to maintain a tight grip on hoses, preventing any potential leaks that could compromise engine performance. The clamp’s design is such that it can be easily installed and removed, facilitating maintenance and repairs.

Grouping for Efficiency

When considering the A1400 and A1700 engines together, it is evident that the Hose Clamp 4901130 serves as a common component across these models. This grouping highlights the clamp’s versatility and its ability to fit into different engine configurations within this power range. Similarly, the A2000 and A2300 engines also benefit from the clamp’s compatibility, ensuring that maintenance and repair processes are streamlined across these higher-powered engines.

By understanding the compatibility of the Cummins Hose Clamp 4901130 with these engine models, technicians and maintenance personnel can ensure that the engines operate efficiently and reliably. This part’s design and functionality make it an essential component for maintaining the integrity of the engine’s hose connections.

Role in Plumbing and Fuel Systems

The Hose Clamp 4901130 is instrumental in ensuring the integrity and efficiency of both plumbing and fuel systems within engine applications.

In plumbing systems, the Hose Clamp secures hoses to fittings, preventing leaks and ensuring a consistent flow of fluids. This is particularly important in systems where water, coolant, or other liquids are transported under pressure. The clamp maintains a tight seal, which is essential for the longevity and reliability of the plumbing system. It also allows for easy maintenance and replacement of hoses without the need for specialized tools.

In fuel systems, the Hose Clamp plays a similarly significant role. It ensures that fuel lines are securely attached to injectors, pumps, and other components, maintaining a sealed environment that prevents fuel leaks. This is vital for safety and performance, as any leakage can lead to inefficient engine operation or hazardous conditions. The clamp’s ability to provide a consistent and reliable seal under varying temperatures and pressures makes it an indispensable component in fuel delivery systems.

Conclusion

The Hose Clamp 4901130 by Cummins is a critical component for maintaining the integrity and efficiency of hose connections in commercial trucks. Its durable construction, ease of installation, and compatibility with various engine models make it a reliable choice for ensuring the safe and efficient operation of truck systems. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and reliability of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.