This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

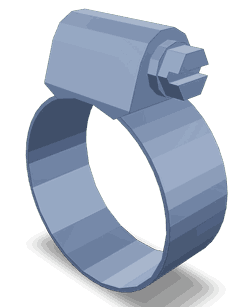

The Cummins 4900368 Hose Clamp is a critical component for commercial trucks, ensuring the integrity of hose connections across various systems. This part plays a significant role in maintaining secure and leak-free connections, which is essential for the efficient operation and safety of commercial vehicles.

Basic Concepts of Hose Clamps

Hose clamps are devices that create secure connections between hoses and fittings by compressing the hose against the fitting, thereby preventing fluid leakage. In automotive and industrial applications, hose clamps are essential for maintaining the flow of fluids such as coolant, fuel, and hydraulic fluids 1.

Purpose of the 4900368 Hose Clamp

The 4900368 Hose Clamp is engineered to support various systems within a truck, including the cooling, fuel, and hydraulic systems. It ensures that hose connections remain tight and secure, which is vital for the consistent performance of these systems 2.

Key Features

This Cummins part is constructed from high-quality materials that offer durability and resistance to corrosion. Its design includes a band that can be tightened using a screwdriver or wrench, allowing for precise adjustment. The clamp features a unique tooth pattern that grips the hose effectively, enhancing its performance and longevity.

Benefits

Utilizing the 4900368 Hose Clamp provides several advantages. It offers improved seal integrity, which is crucial for preventing leaks. The clamp is designed for ease of installation, reducing downtime during maintenance. Additionally, its robust construction ensures long-term reliability, contributing to the overall efficiency of the truck’s systems 3.

Installation Process

To install the 4900368 Hose Clamp, first, ensure the hose and fitting are clean and free of debris. Position the clamp around the hose and fitting, then use a screwdriver or wrench to tighten the band until the desired compression is achieved. It is important to follow the manufacturer’s guidelines for torque specifications to ensure optimal performance.

Troubleshooting Common Issues

Common issues with hose clamps include leaks and clamp failure. If a leak is detected, inspect the clamp for proper installation and ensure it is tightened to the correct specification. If the clamp appears damaged or worn, replacement may be necessary to restore system integrity.

Maintenance Tips

Regular maintenance of the 4900368 Hose Clamp involves periodic inspection for signs of wear or corrosion. Cleaning the clamp and surrounding areas can prevent buildup that may affect performance. Replacement should be considered if the clamp shows significant wear or if leaks persist after tightening.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company offers a wide range of products designed to meet the demanding requirements of commercial transportation 4.

Cummins Hose Clamp 4900368 Compatibility

The Cummins Hose Clamp 4900368 is a versatile component designed to fit seamlessly with various Cummins engines. This part is engineered to ensure a secure and leak-proof connection between hoses and fittings, which is crucial for maintaining the integrity of the engine’s cooling, fuel, and exhaust systems.

A2300 Engine Group

The A2300 engine series, known for its reliability and efficiency, is one of the key beneficiaries of the 4900368 Hose Clamp. This clamp is specifically designed to fit the precise specifications of the A2300 engines, ensuring that all connections are tight and secure. The clamp’s robust construction and high-quality materials make it an ideal choice for maintaining the performance and longevity of the A2300 engines.

Other Cummins Engines

While the primary focus here is on the A2300 engine, the 4900368 Hose Clamp is also compatible with a range of other Cummins engines. Its universal design allows it to fit various engine models, making it a valuable component for maintenance and repair across multiple engine types. This compatibility ensures that technicians and fleet managers can rely on this clamp for a wide array of applications, enhancing the overall maintenance process.

Role of Part 4900368 Hose Clamp in Engine Systems

The 4900368 Hose Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. In the context of an engine oil system, this hose clamp plays a significant role in maintaining the integrity of the oil circulation path. It is employed to fasten hoses that connect the engine oil pump to the oil filter, and subsequently to the engine block. This ensures that oil is delivered under pressure to lubricate moving parts, reduce friction, and dissipate heat effectively.

Similarly, in a cooling system, the 4900368 Hose Clamp is utilized to secure hoses that route coolant between the engine and the radiator. This is vital for maintaining optimal engine temperature by ensuring a consistent flow of coolant, which absorbs heat from the engine and transfers it to the radiator for dissipation. The clamp’s ability to provide a tight seal prevents leaks, which could lead to engine overheating and potential damage.

Furthermore, the clamp is also integral in systems where hoses connect to the turbocharger, intercooler, or any auxiliary cooling systems. It ensures that these components receive the necessary fluids without interruption, contributing to the overall efficiency and reliability of the engine system.

Conclusion

In summary, the 4900368 Hose Clamp is a fundamental component in various engine systems, facilitating the secure connection of hoses and ensuring the uninterrupted flow of essential fluids. Its robust construction, ease of installation, and compatibility with a wide range of Cummins engines make it an invaluable part for maintaining the performance and reliability of commercial trucks.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.