This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

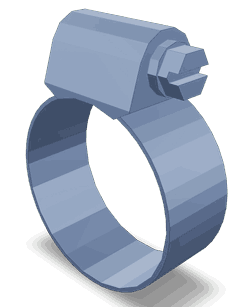

The Hose Clamp 4900279, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems aimed at enhancing the performance and reliability of trucks. This Cummins part is significant in this context as it plays a role in securing hoses within various truck systems, ensuring efficient operation and safety 1.

Basic Concepts of Hose Clamps

Hose clamps are devices used to secure hoses to fittings, ensuring a tight and leak-free connection. They are essential in various applications where hoses transport fluids or gases. There are several types of hose clamps, including worm gear, spring, and screw-type clamps, each suited to different applications based on the required clamping force and environmental conditions 2.

Purpose of Hose Clamp 4900279 in Truck Operations

This part is utilized in commercial trucks to secure hoses in systems such as fuel, coolant, and pneumatic systems. Its role is to maintain a secure connection, preventing leaks and ensuring the efficient transfer of fluids or gases. This clamp is particularly important in environments where vibrations and temperature fluctuations are common, as it helps maintain the integrity of the hose connections under such conditions 3.

Key Features of Hose Clamp 4900279

The Hose Clamp 4900279 is designed with specific features to enhance its performance and durability. It is constructed from high-quality materials that offer resistance to corrosion and wear. The clamp features a worm gear mechanism, which allows for precise adjustment and a strong clamping force. Additionally, its design includes features that facilitate easy installation and removal, making it a practical choice for maintenance and repair tasks 4.

Benefits of Using Hose Clamp 4900279

Using the Hose Clamp 4900279 offers several advantages. It provides improved seal integrity, reducing the risk of leaks in critical systems. The ease of installation is another benefit, allowing for quick and efficient maintenance. Furthermore, its resistance to environmental factors such as moisture, chemicals, and temperature extremes ensures long-term reliability in demanding truck operations 5.

Installation and Usage Guidelines

To install the Hose Clamp 4900279, first, ensure the hose and fitting are clean and free of debris. Slide the clamp onto the hose, positioning it close to the fitting. Use the worm gear mechanism to tighten the clamp until the desired tension is achieved, ensuring a secure connection without over-tightening, which could damage the hose. Regular checks should be performed to ensure the clamp remains secure and the connection is leak-free.

Maintenance and Troubleshooting

Maintaining the Hose Clamp 4900279 involves regular inspection for signs of wear, corrosion, or damage. If leaks are detected, the clamp should be checked for proper tension and alignment. In cases of clamp failure, replacement with a new Hose Clamp 4900279 is recommended to ensure system integrity. Keeping the clamp and surrounding areas clean can also help prevent issues related to contamination.

Compatibility and Applications

The Hose Clamp 4900279 is compatible with a range of hose sizes and types commonly used in commercial trucks. It is applied in various systems, including fuel lines, coolant systems, and pneumatic lines, where secure and reliable hose connections are required.

Safety Considerations

When installing, maintaining, or troubleshooting the Hose Clamp 4900279, it is important to follow safety guidelines. Ensure the truck is turned off and the system is depressurized before beginning work. Use appropriate personal protective equipment (PPE) to protect against potential hazards. Always refer to the manufacturer’s instructions for specific safety recommendations and best practices.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company offers a wide range of products for commercial vehicles, including engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of the industry.

Cummins Hose Clamp 4900279 Compatibility with Engine Models

The Cummins Hose Clamp part number 4900279 is designed to fit seamlessly with a range of engine models, ensuring a secure and reliable connection for various fluid and gas lines. This clamp is engineered to maintain the integrity of the engine’s systems by preventing leaks and maintaining pressure.

A1400 and A1700 Engines

The A1400 and A1700 engines benefit from the use of the 4900279 Hose Clamp. These engines, known for their robust performance and reliability, require precise fitting components to ensure optimal operation. The clamp’s design allows for easy installation and removal, making it a practical choice for maintenance and repairs.

A2000 and A2300 Engines

Similarly, the A2000 and A2300 engines are compatible with the 4900279 Hose Clamp. These engines, which are part of the Cummins lineup, are designed for heavy-duty applications and benefit from the clamp’s ability to withstand high pressures and temperatures. The clamp’s durability ensures that it can maintain a tight seal over the engine’s operational life, contributing to the engine’s overall efficiency and longevity.

Grouping for Efficiency

When considering the use of the 4900279 Hose Clamp across the A1400, A1700, A2000, and A2300 engines, it is evident that this part is versatile and designed to meet the demands of various engine configurations. Its compatibility with these engines highlights its importance in maintaining the integrity of the engine’s systems, ensuring that each engine operates at peak performance.

Role of Part 4900279 Hose Clamp in Engine Systems

The part 4900279 Hose Clamp is a critical component in ensuring the integrity and efficiency of various engine systems. When integrated into the fuel system, this hose clamp secures the fuel lines, preventing leaks and maintaining consistent fuel pressure. This is particularly important in high-performance engines where fuel delivery precision can significantly impact engine performance and reliability.

In the filtration system, the hose clamp plays a similarly vital role. It ensures that the connections between the filter housing and the associated hoses remain tight and secure. This prevents any bypass of contaminants, ensuring that the filter performs its function effectively. Proper sealing here is essential for maintaining the cleanliness of the engine’s lubricants, which in turn protects internal engine components from wear and tear.

Additionally, the hose clamp is used in various other systems where fluid transfer is necessary, such as coolant systems and hydraulic lines. Its role in these applications is to provide a reliable connection that can withstand the pressures and temperatures associated with engine operation. This ensures that all fluid systems operate within their designed parameters, contributing to the overall efficiency and longevity of the engine.

Conclusion

The Hose Clamp 4900279 by Cummins is a vital component in the maintenance and operation of commercial trucks and engines. Its design, featuring high-quality materials and a worm gear mechanism, ensures durability, ease of use, and reliable performance. The clamp’s compatibility with various engine models and its role in securing critical hose connections underscore its importance in ensuring the efficiency and safety of truck operations. Regular maintenance and adherence to safety guidelines are essential to maximize the benefits of this part.

-

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩ -

Robert Bosch GmbH. Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH, 2014.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4326162, QSB4.5 CM2150 B108.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.