This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4897546 Plain Hose is a component designed for use in commercial truck systems. It serves as a conduit for transporting various fluids within the truck’s system, ensuring efficient operation and maintenance of critical functions.

Basic Concepts of Plain Hoses

Plain hoses are flexible tubes used in automotive and industrial applications to transfer fluids such as coolant, fuel, oil, and air. They are constructed from materials that offer flexibility, durability, and resistance to the specific fluids they transport. Within a system, plain hoses allow for movement and vibration without compromising the integrity of the fluid transfer 1.

Purpose of the Cummins 4897546 Plain Hose

The Cummins 4897546 Plain Hose plays a specific role in the operation of a truck by connecting various systems and transporting essential fluids. It is integral to maintaining the functionality of the truck’s engine and other components by ensuring a reliable and leak-free flow of fluids 2.

Key Features

The Cummins 4897546 Plain Hose is characterized by several key features that enhance its performance and longevity. These include a material composition designed for durability and resistance to the fluids it transports, flexibility to accommodate movement and vibration, and a design that ensures a secure fit within the truck’s system.

Benefits of Using Cummins 4897546 Plain Hose

Utilizing the Cummins 4897546 Plain Hose offers several advantages. It contributes to improved system efficiency by providing a reliable conduit for fluid transfer. The hose’s design reduces the risk of leaks, which can lead to system failures or inefficiencies. Additionally, its durability ensures long-term performance, making it a cost-effective solution for truck maintenance 3.

Installation Considerations

Proper installation of the Cummins 4897546 Plain Hose is vital for ensuring its effectiveness and longevity. Best practices include using the appropriate tools for a secure fit, following manufacturer guidelines for connection points, and avoiding common pitfalls such as over-tightening or under-tightening fittings. Careful attention to these details during installation can prevent future issues and ensure optimal performance.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 4897546 Plain Hose, regular maintenance is recommended. This includes inspecting the hose for signs of wear, checking for leaks, and ensuring all connections are secure. Common issues such as leaks or wear can often be resolved through proper maintenance practices, including timely replacement of worn sections or damaged fittings 4.

Safety Considerations

When working with the Cummins 4897546 Plain Hose, it is important to follow safety practices to prevent accidents and ensure user safety. This includes wearing appropriate personal protective equipment, ensuring the work area is well-ventilated when dealing with fluid transfers, and following all manufacturer guidelines for handling, installation, and maintenance.

Environmental Impact

The use and disposal of the Cummins 4897546 Plain Hose should be considered in the context of environmental impact. Proper disposal methods, including recycling where possible, can help minimize the environmental footprint of this component. Additionally, choosing hoses made from environmentally friendly materials can contribute to sustainable practices in truck maintenance and operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a commitment to quality and innovation, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications, from on-highway to off-highway and industrial uses.

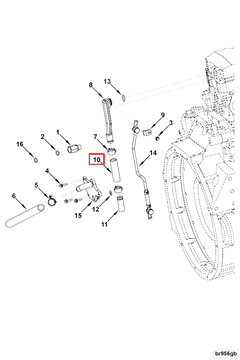

Role of Part 4897546 Plain Hose in Engine Systems

In the context of engine systems, the Part 4897546 Plain Hose is instrumental in facilitating the efficient operation of several key components.

Breather System Integration

The breather system is designed to manage the pressure within the engine’s crankcase by allowing air to escape. The Part 4897546 Plain Hose connects the breather to the intake manifold or another suitable outlet. This connection ensures that the expelled air, which may contain moisture and contaminants, is directed away from the engine compartment. By maintaining a balanced pressure, the hose helps prevent oil leaks and ensures that the breather system operates effectively, contributing to the overall health of the engine.

Crankcase Ventilation

In the crankcase ventilation system, the Part 4897546 Plain Hose plays a significant role by providing a pathway for gases to be vented from the crankcase. These gases, which include unburned fuel and combustion byproducts, need to be efficiently removed to prevent buildup that could lead to increased pressure and potential damage. The hose ensures that these gases are routed to the intake system where they can be re-burned, thus reducing emissions and enhancing engine performance.

By integrating the Part 4897546 Plain Hose into these systems, engineers and mechanics can ensure that the engine operates within optimal parameters, promoting longevity and reliability.

Conclusion

The Cummins 4897546 Plain Hose is a vital component in the operation and maintenance of commercial truck systems. Its role in facilitating the transfer of essential fluids, combined with its durability and design features, makes it a critical part of ensuring engine efficiency and reliability. Proper installation, maintenance, and consideration of environmental impact are essential for maximizing the benefits of this component.

-

Vaclav Smil, The History and Impact of Diesel Engines and Gas Turbines, The MIT Press, 2010.

↩ -

Tim Giles, Automotive Engines Diagnosis Repair and Rebuilding, Cengage Learning, 2019.

↩ -

John Kasab and Andrea Strzelec, Automotive Emissions Regulations and Exhaust Aftertreatment Systems, SAE International, 2020.

↩ -

Frederick F. Ling, The Automotive Body, Springer Science, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.