This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4382133 Molded Hose is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s system, contributing to the overall efficiency and reliability of truck operations. Understanding its purpose and significance is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Molded Hoses

Molded hoses are specialized components used in various automotive and industrial applications. They are manufactured through a process that involves molding synthetic rubber or other materials around embedded textile or wire reinforcements. This construction method provides molded hoses with the flexibility, strength, and durability required for transporting fluids under pressure within automotive systems. Their applications range from fuel lines to coolant systems, playing a vital role in ensuring the smooth operation of vehicles 1.

Purpose of the 4382133 Molded Hose

This Cummins part is integral to the operation of a truck, connecting specific systems and facilitating the transport of fluids. It is designed to link components within the truck’s system, ensuring the efficient transfer of fluids necessary for the vehicle’s operation. The hose’s role in maintaining the integrity of the fluid transport system is significant, contributing to the overall performance and reliability of the truck 2.

Key Features

The design and construction of the 4382133 Molded Hose incorporate several features that enhance its performance and durability. It is made from high-quality materials that provide resistance to wear, tear, and environmental factors. The hose features specific connection types that ensure a secure fit within the truck’s system, minimizing the risk of leaks and ensuring efficient fluid transport. Its unique attributes are tailored to meet the demanding conditions encountered in commercial truck operations 3.

Benefits

The 4382133 Molded Hose offers several advantages that contribute to its reliability and performance. Its construction materials and design features provide resistance to wear and tear, ensuring longevity even under demanding conditions. The hose’s ability to maintain a secure fit and seal within the truck’s system enhances its reliability, reducing the likelihood of fluid leaks and system failures. These benefits contribute to the overall efficiency and safety of truck operations 4.

Installation Considerations

Installing the 4382133 Molded Hose requires attention to detail and adherence to best practices to ensure proper fit and sealing. Necessary tools and preparation steps should be followed to facilitate a smooth installation process. Ensuring the hose is correctly positioned and securely connected within the truck’s system is crucial for its performance and the vehicle’s operation. Proper installation contributes to the hose’s longevity and the system’s reliability 5.

Troubleshooting Common Issues

Common problems associated with molded hoses, such as leaks, cracks, and blockages, can arise due to wear, environmental factors, or installation issues. Identifying these problems early and applying appropriate troubleshooting steps can prevent system failures and ensure the continued operation of the truck. Solutions may include repairing or replacing the hose, depending on the issue’s severity and the hose’s condition 6.

Maintenance Tips

Regular maintenance practices are vital for ensuring the longevity and optimal performance of the 4382133 Molded Hose. Inspection intervals should be established to monitor the hose’s condition and identify any signs of wear or damage. Replacement guidelines should be followed to ensure the hose is replaced before it fails, contributing to the system’s reliability and the truck’s overall performance. Consistent maintenance practices help maintain the efficiency and safety of truck operations 7.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality. With a history of innovation and excellence, Cummins has established a reputation for producing reliable and high-performance components for commercial vehicles. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of the commercial truck industry 8.

Engine Compatibility with Molded Hose Part 4382133

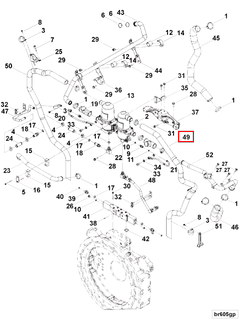

This Cummins part is designed to fit seamlessly with several models of Cummins engines. This part is integral to the engine’s operation, ensuring the proper flow of fluids and gases within the system. Below is a detailed description of how this hose integrates with the specified engine models.

QSK60 CM2350 K116, QSK60 CM2350 K117, QSK60 CM2350 K121

This hose is compatible with the QSK60 CM2350 K116, QSK60 CM2350 K117, and QSK60 CM2350 K121 engines. This hose is engineered to connect critical components within these engines, ensuring that the fluid pathways remain intact and efficient. The design of the hose allows for flexibility and durability, accommodating the dynamic movements and vibrations inherent in these engines.

QSK60 CM2350 K135, QSK60 CM2350 K136

Similarly, this hose is also compatible with the QSK60 CM2350 K135 and QSK60 CM2350 K136 engines. These engines, like their counterparts, rely on this hose to maintain the integrity of their fluid systems. The hose’s material and construction are specifically chosen to withstand the operational conditions of these engines, ensuring longevity and reliability.

Installation and Maintenance

When installing this hose, it is crucial to follow the manufacturer’s guidelines to ensure a proper fit and function. Regular maintenance checks should be conducted to inspect for any signs of wear or damage, as the hose’s integrity is vital for the engine’s performance. Any detected issues should be addressed promptly to prevent potential system failures 9.

Role of Part 4382133 Molded Hose in Engine Systems

This part is an essential component in the efficient operation of several engine systems. It is primarily utilized in the management and regulation of various fluids and gases within the engine, ensuring optimal performance and longevity.

In the crankcase breather system, this hose plays a significant role. It facilitates the release of pressure built up within the crankcase, allowing for the safe venting of gases and vapors produced during engine operation. This process is vital for maintaining the integrity of the crankcase and preventing the accumulation of harmful contaminants.

Additionally, the hose is integral to the CRC breather arrangement. Here, it aids in the circulation and filtration of crankcase gases, ensuring that any moisture or debris is effectively managed. This contributes to the overall cleanliness of the engine’s internal components, reducing wear and enhancing efficiency.

Furthermore, this hose is employed in the broader breather arrangement of the engine. It connects various components, allowing for the seamless flow of gases and fluids. This arrangement is designed to maintain a balanced pressure within the engine, which is essential for stable operation and performance.

In summary, this hose is a key element in the engine’s breather and crankcase systems. Its role in managing pressure, facilitating the circulation of gases, and ensuring the cleanliness of internal components is fundamental to the engine’s efficient and reliable operation 10.

Conclusion

The 4382133 Molded Hose by Cummins is a critical component in the operation of commercial trucks, particularly in the management of engine systems. Its design, featuring high-quality materials and specific connection types, ensures efficient fluid transport and system reliability. Regular maintenance and proper installation are essential for maximizing its performance and longevity, contributing to the overall efficiency and safety of truck operations.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504277.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504277.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504277.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504277.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504277.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504277.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504277.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.