This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

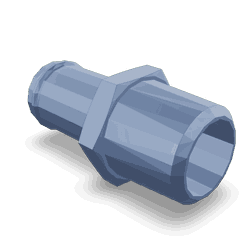

The Cummins 4371571 Plain Hose Coupling is designed for use in commercial truck systems, connecting hoses within fluid transfer systems to ensure secure and efficient fluid transfer. This coupling is vital for maintaining the operational integrity of truck systems by providing a reliable connection point for hoses.

Basic Concepts of Plain Hose Couplings

Plain hose couplings join hoses or a hose to a fitting without clamps or additional fasteners, creating a tight seal for fluid transfer under pressure. They are used in applications requiring flexibility, ease of installation, and reliable performance, especially where hoses need frequent connection and disconnection 1.

Purpose of the Cummins 4371571 Plain Hose Coupling

This Cummins part facilitates the connection of hoses in fluid transfer systems, ensuring efficient and leak-free transfer of fluids such as coolant, fuel, or hydraulic fluid. It is designed to withstand the pressures and conditions typical in truck systems, providing a durable and reliable connection 2.

Key Features

The Cummins 4371571 Plain Hose Coupling is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. Its design facilitates easy installation and removal, reducing downtime during maintenance. The coupling features a robust seal mechanism that maintains integrity under pressure, preventing leaks and ensuring efficient fluid transfer 3.

Benefits

This part offers several advantages in fluid transfer applications. Its design allows for quick and easy installation, minimizing maintenance or repair time. The reliable seal ensures efficient and leak-free fluid transfer, contributing to the overall performance of the truck’s systems. The durability of the coupling means it can withstand the rigors of commercial use, reducing the need for frequent replacements.

Installation Process

Installing the Cummins 4371571 Plain Hose Coupling involves cleaning the hoses, positioning the coupling over one end of the hose, and pushing it until it reaches the stop position. The second hose is then inserted into the coupling and pushed until it meets resistance. It is important to follow the manufacturer’s guidelines to avoid over-insertion, which could damage the coupling or the hoses.

Maintenance Tips

To ensure optimal performance and longevity, regular maintenance is recommended. This includes inspecting the coupling for signs of wear or damage, cleaning it to remove any buildup, and replacing it if any issues are detected. Following the manufacturer’s guidelines for installation and use can help maintain the integrity of the coupling over time.

Troubleshooting Common Issues

Common issues may include leaks, difficulty in installation or removal, or damage to the coupling. To address these problems, ensure the coupling is correctly installed according to the manufacturer’s instructions. If leaks occur, inspect the coupling and hoses for damage or misalignment. Replacing the coupling may be necessary to resolve the issue. Regular maintenance and inspection can help identify potential problems before they lead to significant issues.

Safety Considerations

When working with the Cummins 4371571 Plain Hose Coupling, it is important to follow safety precautions to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against fluid spills or debris. Additionally, ensuring that the truck’s systems are depressurized before attempting any maintenance or repairs can help prevent injuries. Following the manufacturer’s guidelines for installation, use, and maintenance is crucial to maintaining safety and efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for manufacturing reliable and high-performance automotive components. The company’s focus on customer satisfaction and technological advancement ensures that its products, including the Cummins 4371571 Plain Hose Coupling, meet the demanding requirements of commercial applications.

Cummins Engine Compatibility with Plain Hose Coupling Part 4371571

The Plain Hose Coupling part 4371571, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is essential for ensuring proper fluid transfer and maintaining the integrity of the engine’s cooling and fuel systems. Below is a detailed description of how this part integrates with various Cummins engines.

ISG12 G CMOH6.0 G111 and QSK19 CM2350 K114 Engines

The Plain Hose Coupling part 4371571 is compatible with the ISG12 G CMOH6.0 G111 and QSK19 CM2350 K114 engines. These engines, known for their robust performance and reliability, benefit from the precise fit and durability of this coupling. The part ensures that hose connections remain secure, preventing leaks and maintaining optimal system pressure.

X11 CM2670 X126B and X12 CM2670 X121B Engines

For the X11 CM2670 X126B and X12 CM2670 X121B engines, the Plain Hose Coupling part 4371571 is engineered to fit perfectly, ensuring efficient fluid transfer. These engines, which are part of Cummins’ lineup of high-performance diesel engines, rely on this coupling to maintain system integrity and performance.

X12N CMMDG1 X143B and X13 CM2670 X122B Engines

The Plain Hose Coupling part 4371571 is also compatible with the X12N CMMDG1 X143B and X13 CM2670 X122B engines. These engines, known for their versatility and power, require a reliable hose coupling to ensure that all fluid systems operate smoothly. The part’s design ensures a tight seal, preventing any potential fluid loss and maintaining system efficiency.

Conclusion

The Plain Hose Coupling part 4371571 is a critical component for maintaining the performance and reliability of various Cummins engines. Its compatibility with the ISG12 G CMOH6.0 G111, QSK19 CM2350 K114, X11 CM2670 X126B, X12 CM2670 X121B, X12N CMMDG1 X143B, and X13 CM2670 X122B engines ensures that these engines can operate efficiently and without leaks.

Role of Part 4371571 Plain Hose Coupling in Engine Systems

The Part 4371571 Plain Hose Coupling is an essential component in various engine systems, facilitating the secure and efficient connection of hoses to different parts of the engine. Its application spans across several key components, ensuring optimal performance and reliability.

Integration with the Engine Cover

In engine systems, the cover serves as a protective enclosure for internal components. The Plain Hose Coupling is often used to connect cooling or lubrication hoses to the engine cover. This connection ensures that fluids are efficiently circulated to and from the cover, maintaining the integrity and performance of the enclosed components.

Connection to the Cam Follower

The cam follower is a component that interacts directly with the camshaft to control the opening and closing of valves. The Plain Hose Coupling may be employed to link hydraulic lines to the cam follower system. This connection is vital for systems that use hydraulic actuation, ensuring precise and reliable valve operation.

Role in Plumbing Systems

Within the broader context of engine plumbing, the Plain Hose Coupling is instrumental in joining various hoses that transport fluids such as coolant, oil, and hydraulic fluid. Its robust design ensures a leak-free connection, which is essential for maintaining the efficiency and safety of the engine’s fluid systems.

Auxiliary Cooling Systems

Engines often incorporate auxiliary cooling systems to manage thermal loads, especially in high-performance or heavy-duty applications. The Plain Hose Coupling is used to connect hoses in these systems, facilitating the flow of coolant to and from additional radiators or heat exchangers. This helps in dissipating excess heat, thereby protecting the engine from overheating and ensuring consistent performance under varying conditions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.