This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

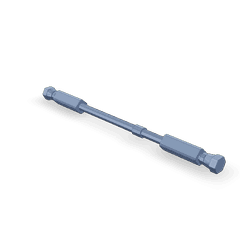

The Cummins 4368805 Flexible Hose is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by facilitating the transfer of fluids between various systems. Understanding its purpose and functionality is key to maintaining the efficiency and reliability of truck operations.

Basic Concepts of Flexible Hoses

Flexible hoses are used in automotive systems to connect different components, allowing for the transfer of fluids such as coolant, fuel, and hydraulic fluids. They are designed to accommodate movement and vibration, which are common in vehicle operations, thus providing a reliable connection that can withstand the dynamic environment of a commercial truck 1.

Purpose of the 4368805 Flexible Hose

The Cummins 4368805 Flexible Hose is specifically engineered to connect systems within a truck, transporting fluids that are vital for the operation of the vehicle. It plays a role in ensuring that these fluids reach their intended destinations without leakage or disruption, contributing to the overall performance and longevity of the truck’s systems.

Key Features

The 4368805 Flexible Hose is characterized by several key features that enhance its performance and durability. These include its material composition, which is designed to resist wear and corrosion, its flexibility to accommodate movement, and its robust design specifications that ensure a secure and lasting connection. These features collectively contribute to the hose’s ability to perform under the demanding conditions of commercial truck operations 2.

Benefits

Utilizing the Cummins 4368805 Flexible Hose offers several advantages. Its design allows for improved flexibility, which helps in accommodating the movements and vibrations typical in truck operations. This flexibility reduces the risk of leaks, enhances the durability of the connection, and simplifies the installation process, making it a valuable component for maintaining the efficiency of truck systems.

Installation Process

Installing the Cummins 4368805 Flexible Hose requires following a series of steps to ensure a secure fit. The process involves preparing the connection points, using the appropriate tools to attach the hose, and verifying the connections to prevent leaks. Detailed instructions on the installation process are provided to ensure that the hose is correctly installed, contributing to the safe and efficient operation of the truck.

Troubleshooting Common Issues

Common issues with flexible hoses, such as leaks, cracks, and kinks, can arise due to wear and tear or improper installation. Identifying these problems early and applying the correct troubleshooting steps can help in resolving issues and preventing further damage. Solutions may include tightening connections, replacing damaged sections, or adjusting the hose to remove kinks.

Maintenance Tips

Regular maintenance of the Cummins 4368805 Flexible Hose is important for prolonging its life and ensuring reliable operation. This includes inspecting the hose for signs of wear or damage, cleaning it to remove any buildup that could affect performance, and following replacement guidelines to maintain the integrity of the fluid transfer system.

Safety Considerations

When handling, installing, or maintaining the Cummins 4368805 Flexible Hose, it is important to observe safety protocols to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the truck is properly secured before beginning work, and following all manufacturer guidelines for installation and maintenance. These precautions help in ensuring the safe operation of the vehicle and the safety of those working on it.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a broad product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for delivering reliable and high-performance solutions. The company’s history of excellence and dedication to advancing technology underscores its position as a trusted partner in the commercial trucking sector 3.

Cummins Part 4368805: Flexible Hose Compatibility with K19 Engines

The Cummins part 4368805, a Flexible Hose, is designed to integrate seamlessly with the K19 engine series. This part is engineered to meet the stringent requirements of the K19 engines, ensuring optimal performance and durability. The flexibility of the hose allows it to adapt to various configurations and movements within the engine compartment, providing a reliable connection that can withstand the rigors of engine operation.

Integration with K19 Engines

The K19 engine series, known for its robust design and efficiency, benefits significantly from the use of the Cummins part 4368805. This flexible hose is specifically tailored to fit the unique layout and requirements of the K19 engines, ensuring that it can connect various components without compromising on performance. The hose’s design allows it to handle the dynamic stresses and movements inherent in engine operation, providing a stable and secure connection.

Grouping with Other Cummins Engines

While the primary focus here is on the K19 engines, it is worth noting that the Cummins part 4368805 is also compatible with other Cummins engine models. This flexibility in compatibility ensures that the part can be used across a range of engine types, providing a versatile solution for engine maintenance and repair. The design of the hose is such that it can be adapted to fit the specific needs of different engine configurations, making it a valuable component for engine technicians and maintenance professionals.

Application Considerations

When applying the Cummins part 4368805 to K19 engines, it is important to consider the specific requirements of the engine and the operating environment. The hose should be installed in a manner that ensures it can move freely without causing undue stress on the connections. Proper installation and maintenance of the hose are crucial to prevent leaks and ensure the longevity of the engine components it connects. Technicians should follow the manufacturer’s guidelines for installation and regularly inspect the hose for signs of wear or damage.

Role of Part 4368805 Flexible Hose in Engine Systems

The part 4368805 Flexible Hose is an essential component in various engine systems, facilitating the transfer of fluids between different parts of the engine. Its primary function is to connect rigid components, allowing for movement and vibration without compromising the integrity of the fluid transfer.

In the context of an exchanger, the flexible hose plays a significant role in connecting the exchanger to other components such as the engine block or radiator. This connection ensures that coolant or other fluids can circulate efficiently, maintaining optimal operating temperatures and preventing overheating. The flexibility of the hose accommodates the thermal expansion and contraction of the components, ensuring a secure and durable connection.

Similarly, in a heat exchanger system, the flexible hose is used to connect the heat exchanger to the engine’s cooling system. This allows for the efficient transfer of heat from the engine to the cooling fluid, which is then circulated back to the radiator for cooling. The hose’s flexibility is particularly important in this application, as it must withstand the constant expansion and contraction of the heat exchanger due to temperature fluctuations.

Overall, the part 4368805 Flexible Hose is integral to the proper functioning of engine systems, ensuring reliable fluid transfer and accommodating the dynamic nature of engine components.

Conclusion

The Cummins 4368805 Flexible Hose is a critical component in the maintenance and operation of commercial trucks and engines. Its design, featuring flexibility, durability, and compatibility with various engine models, ensures reliable fluid transfer and accommodates the dynamic nature of engine components. Proper installation, maintenance, and adherence to safety protocols are essential to maximize the performance and longevity of this part, contributing to the overall efficiency and reliability of truck and engine systems.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.