This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

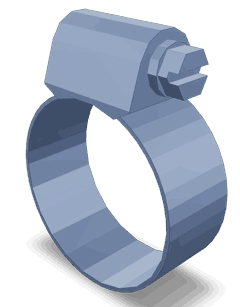

The Cummins Hose Clamp 4364426 is a specialized component designed for use in commercial truck systems. It serves to secure hoses in various fluid systems, ensuring that connections remain tight and secure under operational conditions. This clamp is integral to maintaining the integrity of fluid pathways in trucks, contributing to the overall reliability and performance of the vehicle 1.

Basic Concepts of Hose Clamps

Hose clamps are mechanical devices used to secure hoses to fittings in automotive and industrial applications. They operate by compressing the hose against the fitting, creating a seal that prevents leaks and ensures the efficient transfer of fluids. Hose clamps come in various designs, including worm-drive, spring, and screw-type clamps, each suited to different applications based on the required clamping force and ease of installation 2.

Purpose of the Cummins Hose Clamp 4364426

The Cummins Hose Clamp 4364426 is specifically designed to play a role in the operation of commercial trucks by securing hoses in fuel, coolant, and other fluid systems. Its application ensures that hoses remain firmly attached to their fittings, preventing leaks and maintaining the efficiency of fluid transfer within the truck’s systems. This clamp is engineered to withstand the vibrations and pressures typical in truck operations, ensuring a secure and reliable connection 3.

Key Features

The Cummins Hose Clamp 4364426 features a durable material composition, typically including stainless steel or high-strength alloys, which contribute to its resistance against corrosion and wear. Its design incorporates elements that enhance performance, such as a worm-drive mechanism for precise clamping force adjustment and a wide band for even pressure distribution across the hose. These features differentiate it from other hose clamps by providing superior reliability and ease of use in demanding applications.

Benefits of Using Cummins Hose Clamp 4364426

Utilizing the Cummins Hose Clamp 4364426 offers several advantages. Its durability ensures long-term performance, reducing the need for frequent replacements. The ease of installation, facilitated by its worm-drive design, allows for quick adjustments and secure fittings. Its reliability in securing hoses contributes to the overall efficiency of the truck’s systems by preventing leaks and ensuring consistent fluid flow. These benefits make it a valuable component in maintaining the operational integrity of commercial trucks.

Installation and Usage Guidelines

Proper installation of the Cummins Hose Clamp 4364426 involves several steps to ensure optimal performance and longevity. Begin by selecting the appropriate clamp size for the hose diameter. Position the clamp around the hose and fitting, ensuring it is aligned correctly. Use the worm-drive mechanism to tighten the clamp gradually, applying even pressure until the desired clamping force is achieved. Avoid over-tightening to prevent damage to the hose. Regular checks should be performed to ensure the clamp remains secure and the hose shows no signs of wear or damage.

Troubleshooting Common Issues

Common problems associated with hose clamps include leaks or improper sealing, often due to incorrect installation or wear over time. To address these issues, first, ensure the clamp is correctly sized and installed. If a leak is detected, loosen the clamp slightly and retighten it, checking for any signs of damage to the hose or fitting. In cases of persistent leaks, the clamp or hose may need to be replaced. Regular inspections can help identify and resolve issues before they lead to significant problems.

Maintenance Tips

To ensure the Cummins Hose Clamp 4364426 remains in good working condition, regular maintenance checks are recommended. Inspect the clamp and hose for signs of wear, corrosion, or damage at regular intervals. Clean the clamp and fitting surfaces to remove any debris that could affect the seal. Lubricating the worm-drive mechanism can also help maintain its functionality. Addressing any issues promptly can extend the lifespan of the clamp and ensure continued reliable performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck and engine industry. The company’s commitment to excellence is reflected in its diverse product range, which includes components like the Cummins Hose Clamp 4364426, designed to meet the demanding requirements of commercial applications.

Compatibility with KTA19GC CM558 Engines

The Cummins Hose Clamp 4364426 is engineered to fit seamlessly with the KTA19GC CM558 engines, providing a reliable sealing solution for hoses and pipes that transport fluids and gases within the engine’s operational environment. Its design allows for easy installation and removal, facilitating maintenance and repair processes. The clamp’s robust construction ensures it can withstand the high pressures and temperatures typical of engine operations, contributing to the overall efficiency and longevity of the engine.

Role of Part 4364426 Hose Clamp in Engine Systems

The 4364426 Hose Clamp is an essential component in maintaining the integrity and efficiency of various engine systems. It is specifically designed to secure hoses in place, ensuring a tight and reliable connection between different parts of the engine.

In the context of the Module, the Hose Clamp plays a significant role in securing fuel lines and other fluid conduits. This ensures that the module receives a consistent and uninterrupted flow of necessary fluids, which is vital for its optimal operation. The secure fitting prevents leaks and maintains the pressure integrity of the system, which is essential for the module’s performance and longevity.

When it comes to the Fuel Control system, the 4364426 Hose Clamp is instrumental in maintaining the precise delivery of fuel to the engine. By securely clamping the fuel lines, it prevents any potential fuel leaks that could compromise engine performance or pose a safety hazard. Additionally, it ensures that the fuel control system operates within the specified parameters, contributing to the overall efficiency and reliability of the engine.

Conclusion

The Cummins Hose Clamp 4364426 is a critical component for maintaining the integrity and efficiency of commercial truck and engine systems. Its durable construction, ease of installation, and reliable performance make it an invaluable part of the maintenance and repair toolkit for commercial vehicles. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this part in demanding applications.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for F3.8 CM2620 F137B. Bulletin Number 5579516.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.