4357141

Hose Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4357141 Hose Clamp is a component designed for use in commercial truck maintenance. It serves to secure hoses within the truck’s system, ensuring that connections remain tight and secure under various operating conditions. The significance of this hose clamp lies in its role in maintaining the integrity of the truck’s fluid systems, which is vital for the overall performance and reliability of the vehicle.

Basic Concepts of Hose Clamps

Hose clamps are devices used to secure hoses to fittings, ensuring a tight seal that prevents leaks and maintains system pressure. They are commonly constructed from materials such as metal, plastic, or rubber, depending on the specific application and environmental conditions. The primary function of a hose clamp is to provide a consistent and reliable grip on the hose, which is essential for the safe and efficient operation of fluid systems in vehicles 1.

Role of the 4357141 Hose Clamp in Truck Operation

This Cummins part functions within the truck’s system by securing various hose connections. It is applied in systems where hoses transport fluids such as coolant, fuel, or hydraulic fluid. By maintaining a secure connection, the clamp contributes to the overall integrity of the system, ensuring that fluids are delivered efficiently and without leakage. This is particularly important in commercial trucks, where the reliable operation of fluid systems directly impacts the vehicle’s performance and safety.

Key Features

The 4357141 Hose Clamp is characterized by specific design elements and materials that enhance its performance and durability. The band material is selected for its strength and resistance to corrosion, ensuring long-term reliability. The screw design allows for easy adjustment of the clamp’s tension, facilitating a secure fit on various hose diameters. Additionally, the adjustment mechanism is designed for simplicity and effectiveness, enabling quick and precise clamping without the need for specialized tools.

Benefits of Using the 4357141 Hose Clamp

Using this Cummins part offers several advantages. Its design allows for ease of installation, making it a practical choice for both professional mechanics and DIY enthusiasts. The clamp’s reliability under various conditions, including exposure to vibrations and temperature fluctuations, ensures consistent performance. Furthermore, its long-term durability reduces the need for frequent replacements, contributing to cost efficiency and maintenance simplicity.

Troubleshooting Common Issues

Identifying and resolving typical problems associated with hose clamps, such as leaks or improper sealing, is important for maintaining system integrity. Common issues may arise from incorrect clamp tension, damage to the hose or clamp, or environmental factors affecting the materials. Effective maintenance involves regular inspection of the clamp and hose condition, ensuring that connections remain secure and free from leaks. Adjustments or replacements may be necessary to address identified issues, ensuring continued system reliability.

Maintenance Tips

Regular inspection and maintenance practices are recommended to ensure the longevity and effectiveness of the 4357141 Hose Clamp. This includes checking for signs of wear or corrosion on the clamp and hose, ensuring that the clamp tension remains appropriate for the hose diameter, and verifying that all connections are secure. Additionally, cleaning the clamp and hose surfaces can prevent the buildup of debris that may affect performance. Following these practices helps maintain the clamp’s functionality and contributes to the overall reliability of the truck’s fluid systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry, providing reliable solutions for commercial truck operators worldwide 2.

Cummins Hose Clamp 4357141 Compatibility

The Cummins Hose Clamp part number 4357141 is designed to fit a variety of engine models, ensuring a secure and reliable connection for hoses and other components. This part is compatible with several engine series, including the ISX12, ISX12/ISX11.9, ISX15, QSX11.9, QSX15, and X15 series.

ISX Series

The ISX12, ISX12/ISX11.9, and ISX15 engines are part of Cummins’ heavy-duty diesel engine lineup. The ISX12 and ISX12/ISX11.9 engines, both with CM2350 and CM2250 configurations, utilize the 4357141 hose clamp to maintain the integrity of hose connections. Similarly, the ISX15 engine, available in CM2250 and CM2350 configurations, also benefits from this part.

QSX Series

The QSX11.9, QSX15, and QSX15 CM2350 X105 engines are another set of Cummins engines that are compatible with the 4357141 hose clamp. These engines, with their CM2250 and CM2350 configurations, require this clamp to ensure hoses remain securely fastened under various operating conditions.

X15 Series

The X15 CM2350 X116B and X15 CM2450 X134B engines are also part of the Cummins lineup that uses the 4357141 hose clamp. This part is crucial for maintaining the proper sealing and connection of hoses in these engines, ensuring optimal performance and reliability.

By using the 4357141 hose clamp, technicians and fleet managers can ensure that their Cummins engines maintain the necessary hose connections, contributing to the overall efficiency and longevity of the engine systems.

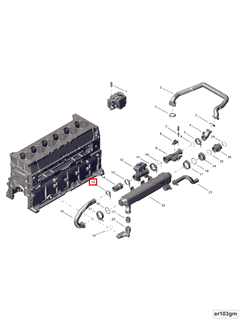

Role of Part 4357141 Hose Clamp in Engine Systems

The 4357141 Hose Clamp is instrumental in maintaining the integrity and efficiency of various engine systems. In the context of the Exhaust Gas Recirculation (EGR) system, this hose clamp ensures a secure connection between the EGR valve and the intake manifold. This connection is vital for the proper recirculation of exhaust gases, which helps in reducing nitrogen oxides (NOx) emissions and improving fuel efficiency.

In the Exhaust Recirculation Air system, the hose clamp plays a significant role by securing the hoses that transport recirculated exhaust gases. This ensures that the gases are effectively mixed with the incoming air-fuel mixture, contributing to a more complete combustion process and lower emissions.

Furthermore, within the overall exhaust system arrangement, the hose clamp is used to connect various components such as the catalytic converter, oxygen sensors, and exhaust manifolds. These connections must be airtight to prevent leaks, which can lead to decreased engine performance and increased emissions.

The hose clamp’s ability to provide a reliable seal is essential for the consistent operation of these systems. It ensures that all connections remain intact under varying engine conditions, including changes in temperature, pressure, and vibration. This reliability is key to maintaining the performance and longevity of the engine systems it supports 3.

Conclusion

The Cummins 4357141 Hose Clamp plays a critical role in the maintenance and operation of commercial trucks. Its design and features ensure secure and reliable hose connections, contributing to the overall efficiency and reliability of the vehicle’s fluid systems. Regular maintenance and proper use of this part are essential for ensuring the longevity and performance of Cummins engines.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.