This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

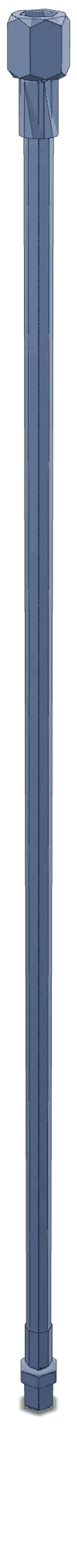

The 4348987 Flexible Hose, manufactured by Cummins, is a critical component in the automotive industry, particularly for heavy-duty trucks. This part facilitates the transfer of fluids or gases within the vehicle’s system, ensuring efficient and reliable truck operations 1.

Basic Concepts of Flexible Hoses

Flexible hoses are essential in automotive applications for connecting various system parts, enabling the transfer of fluids or gases. They are designed to withstand movement and vibration, common in vehicle operations. Materials like rubber, plastic, or metal are chosen for their flexibility, durability, and resistance to specific fluids or gases 2.

Purpose of the 4348987 Flexible Hose

This Cummins part is designed to connect specific systems within a truck, facilitating the transport of fluids or gases. It provides a reliable connection that can withstand dynamic conditions, including various temperatures, pressures, and movements, contributing to the truck’s overall efficiency and safety 3.

Key Features

The 4348987 Flexible Hose features significant flexibility, accommodating movements and vibrations in truck operations. Its construction materials are chosen for their resistance to wear and tear and compatibility with transported fluids or gases. It may also include reinforced layers or specialized coatings for enhanced durability and performance under demanding conditions 4.

Benefits

Using this part in truck applications offers advantages such as greater movement and vibration absorption, reducing damage risk. The materials ensure resistance to wear and tear, providing a longer service life. Its design and materials ensure compatibility with various truck systems, making it versatile for different applications 5.

Installation Considerations

Proper installation of the 4348987 Flexible Hose is vital for optimal performance and safety. Using the correct fitting and securing methods prevents leaks and ensures the hose can withstand operational conditions. Following manufacturer guidelines for installation maintains the integrity of the hose and connected systems 6.

Troubleshooting Common Issues

Common issues with flexible hoses, such as leaks or wear, often result from installation errors or operational wear and tear. Regular inspections help identify potential problems early, allowing for timely repairs or replacements. Safety precautions should be observed when troubleshooting or repairing hoses, including depressurizing the system and safely containing any fluids 7.

Maintenance Tips

Regular maintenance of the 4348987 Flexible Hose ensures longevity and reliable performance. This includes inspecting for wear or damage, cleaning as necessary, and replacing when significant wear is evident or when manufacturer-recommended service intervals are reached. Adhering to these practices maintains the efficiency and safety of the truck’s systems 8.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the automotive industry, focusing on high-quality components for heavy-duty trucks. The company’s history of innovation and commitment to quality is reflected in its wide range of products, including the 4348987 Flexible Hose. Cummins’ dedication to excellence ensures its components meet the demanding requirements of commercial truck applications 9.

Role of Part 4348987 Flexible Hose in Engine Systems

In engine systems, the 4348987 Flexible Hose is instrumental in facilitating the movement and arrangement of various components, ensuring efficient operation and maintenance of the engine’s performance.

Integration with Turbocharger Systems

When integrated with turbocharger systems, the Flexible Hose allows for the necessary flexibility in the exhaust and intake systems. This flexibility accommodates the dynamic movements and thermal expansions that occur during engine operation. By connecting the turbocharger to the exhaust manifold and the intake system, the hose ensures a secure yet flexible connection, which is essential for maintaining the integrity of the exhaust gas recirculation (EGR) and the overall efficiency of the turbocharger 10.

Enhancing Component Arrangement

In the arrangement of engine components, the Flexible Hose plays a significant role by providing the necessary connections between rigid components. This is particularly important in densely packed engine bays where space is at a premium. The hose’s flexibility allows engineers and mechanics to route it around other components without compromising the structural integrity or performance of the engine system 11.

Supporting Efficient Engine Operation

The use of the Flexible Hose in these systems supports efficient engine operation by reducing stress on connected components. This reduction in stress helps prevent leaks and maintains the sealing integrity of the system, which is vital for optimal engine performance and emissions control. Additionally, the hose’s ability to absorb vibrations and movements contributes to the longevity and reliability of the engine system 12.

Conclusion

The 4348987 Flexible Hose by Cummins is a vital component in heavy-duty truck applications, ensuring efficient fluid and gas transfer within the vehicle’s system. Its design, featuring flexibility, durability, and compatibility with various engine systems, contributes to the overall efficiency, safety, and reliability of truck operations. Proper installation, regular maintenance, and understanding its role in engine systems are key to maximizing the benefits of this part.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

Cummins Inc., Engine QSL9 G CM558/CM2358 Panel System, Bulletin Number 2883471, Master Repair Manual.

↩ -

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

Cummins Inc., Engine QSL9 G CM558/CM2358 Panel System, Bulletin Number 2883471, Master Repair Manual.

↩ -

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

Cummins Inc., Engine QSL9 G CM558/CM2358 Panel System, Bulletin Number 2883471, Master Repair Manual.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.