This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

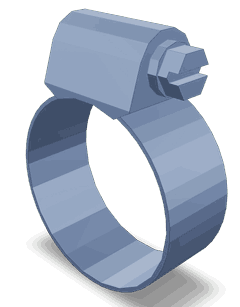

The Cummins 4335538 Hose Clamp is a critical component in commercial truck maintenance and operation, ensuring secure hose connections within various truck systems. This enhances the vehicle’s efficiency and reliability.

Basic Concepts of Hose Clamps

Hose clamps are essential for creating secure connections between hoses and fittings. They apply consistent pressure to ensure a tight seal, preventing leaks and maintaining system integrity in automotive and industrial applications 1.

Purpose of the 4335538 Hose Clamp in Truck Operation

This Cummins part is designed to secure hoses in critical truck systems, including fuel lines, coolant circuits, and pneumatic systems. It ensures a secure and leak-free connection, contributing to efficient system operation and enhancing truck performance and reliability 2.

Key Features of the 4335538 Hose Clamp

The 4335538 Hose Clamp features a robust design and construction, made from high-quality materials that offer durability and corrosion resistance. Its band type design allows for easy adjustment and a secure fit around the hose, enhancing performance and longevity in demanding commercial truck operations 3.

Benefits of Using the 4335538 Hose Clamp

Utilizing this part offers improved reliability in hose connections, reducing the risk of leaks and system failures. It is designed for ease of installation, allowing for quick and efficient setup. Additionally, its durable construction facilitates maintenance efficiency, requiring minimal upkeep over time.

Installation Guidelines

Proper installation of the 4335538 Hose Clamp involves selecting the appropriate clamp size for the hose diameter, placing the clamp around the hose and fitting, and tightening the clamp band evenly with a wrench to achieve a tight seal. Avoid over-tightening to prevent damage to the hose or fitting.

Maintenance and Troubleshooting

Regular maintenance of the 4335538 Hose Clamp is crucial for continued performance. Inspect the clamp for signs of wear or corrosion and replace it if necessary. Look for any indications of leaks or loose connections, which may require adjustment or replacement of the clamp. Troubleshooting common issues involves checking for proper alignment and tension of the clamp, as well as ensuring the hose and fitting are in good condition.

Compatibility and Applications

The 4335538 Hose Clamp is designed for use within Cummins engines and other commercial truck systems. It is commonly applied in various models and series, providing a reliable solution for securing hoses in critical applications.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history and a broad product range, Cummins is renowned for its quality and innovation in the commercial truck and engine industry. The company’s commitment to excellence is reflected in its products, including the 4335538 Hose Clamp, which is designed to meet the high standards of commercial truck operators.

Cummins Hose Clamp 4335538 Compatibility with ISV Engines

The Cummins Hose Clamp part number 4335538 is designed to fit seamlessly with various ISV engines, ensuring a secure and reliable connection for fluid and gas lines. This clamp maintains the integrity of the engine’s cooling and fuel systems, preventing leaks and ensuring optimal performance.

ISV Engines

The ISV engines, manufactured by Nissan, are known for their robust design and efficiency. The Cummins Hose Clamp 4335538 is specifically tailored to integrate with these engines, providing a critical component in the engine’s overall system. Its precision fit ensures that it can withstand the operational pressures and temperatures typical of ISV engines, contributing to the longevity and reliability of the engine.

Application and Installation

When installing the Cummins Hose Clamp 4335538 on ISV engines, it is essential to follow proper procedures to ensure a secure fit. The clamp should be positioned correctly on the hose, and the screw mechanism should be tightened to the manufacturer’s specified torque settings. This ensures that the clamp will not loosen over time, maintaining the integrity of the connection.

Importance of Proper Fit

The correct fit of the hose clamp is crucial for the performance of the ISV engines. An improperly fitted clamp can lead to leaks, which can cause a range of issues from reduced efficiency to complete engine failure. The Cummins Hose Clamp 4335538 is designed to provide a snug fit, preventing such issues and ensuring that the engine operates at peak performance.

Maintenance and Replacement

Regular inspection of the hose clamp is recommended to ensure it remains in good condition. Over time, the clamp may wear out or become damaged, necessitating replacement. Using the correct part number, 4335538, ensures that the replacement clamp is compatible with the ISV engines and will perform as intended.

Hose Clamp Component Usage: Part 4335538

The part 4335538 Hose Clamp is instrumental in ensuring secure and reliable connections within various engine systems. Its primary function is to maintain a tight seal around hoses, preventing leaks and ensuring efficient operation of the engine.

Connection Integrity

In engine systems, the Hose Clamp plays a significant role in maintaining the integrity of connections. It is commonly used to secure hoses to fittings, ensuring that there are no gaps or loose connections that could lead to fluid or air leaks. This is particularly important in systems where precise fluid levels and pressures are required for optimal performance.

Air Transfer Systems

Within air transfer systems, the Hose Clamp is essential for securing air intake and exhaust hoses. It ensures that the air flow is uninterrupted and that there are no leaks in the system. This is vital for maintaining the correct air-fuel ratio in the engine, which directly impacts performance and efficiency. The clamp’s ability to provide a consistent and secure seal helps in reducing the risk of air leaks, which can otherwise lead to decreased engine performance and increased emissions.

Fuel and Coolant Systems

In fuel and coolant systems, the Hose Clamp is used to secure hoses that transport these fluids throughout the engine. A secure connection is necessary to prevent leaks, which can be hazardous and lead to engine damage. The clamp ensures that the hoses remain firmly attached under various operating conditions, including changes in temperature and pressure.

Vacuum Systems

Vacuum systems in engines rely on the Hose Clamp to maintain the integrity of vacuum lines. These lines are critical for various engine functions, including brake boosters and emission control systems. A secure clamp ensures that vacuum is maintained without any leaks, which is essential for the proper functioning of these systems.

Auxiliary Systems

The Hose Clamp is also utilized in various auxiliary systems within the engine, such as power steering and air conditioning systems. In these applications, it ensures that hoses remain securely connected, preventing fluid leaks and maintaining system efficiency. This is particularly important in systems where fluid pressure and temperature can vary significantly.

Conclusion

The 4335538 Hose Clamp is a fundamental component in ensuring the reliability and efficiency of engine systems by providing secure and leak-free connections. Its robust design, ease of installation, and compatibility with various engine systems make it an essential part for commercial truck operators and maintenance professionals.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.