This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

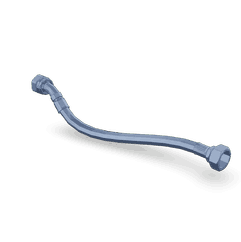

The Cummins 4314220 Flexible Hose is a component designed for use in commercial trucks. It serves as a conduit for various fluids within the truck’s systems, facilitating the transfer of these fluids under varying operational conditions. Its application is integral to maintaining the efficiency and reliability of the truck’s operations.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive applications to connect different parts of a system that may move or vibrate relative to each other. They are designed to accommodate movement and reduce the transmission of vibrations, which can otherwise lead to wear and failure of rigid connections. Within a system, flexible hoses allow for the smooth flow of fluids, gases, or even electrical signals, depending on their specific application 1.

Purpose of the 4314220 Flexible Hose

The 4314220 Flexible Hose plays a role in connecting various systems within a truck, enabling the transport of fluids such as coolant, fuel, or hydraulic fluid. It is engineered to withstand the pressures and temperatures associated with these fluids, ensuring reliable operation across a range of conditions.

Key Features

The 4314220 Flexible Hose is characterized by several key features that enhance its performance and longevity. These include a material composition designed for flexibility and durability, allowing it to bend and twist without compromising the flow of fluids. Its design incorporates elements that resist wear and environmental factors, contributing to its robustness in demanding applications.

Benefits of Using the 4314220 Flexible Hose

Utilizing the 4314220 Flexible Hose offers several advantages. Its flexibility reduces the transmission of vibrations compared to rigid hoses, which can help in minimizing wear on connected components. Additionally, its design provides enhanced resistance to wear and environmental factors, contributing to a longer service life and reduced maintenance requirements 2.

Installation Considerations

When installing the 4314220 Flexible Hose, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes ensuring proper alignment with the systems it connects, using appropriate securing methods to prevent disconnection or movement, and verifying compatibility with the truck’s existing systems to avoid issues such as leaks or reduced efficiency.

Maintenance and Troubleshooting

To maintain the 4314220 Flexible Hose and ensure optimal performance, regular inspection routines are recommended. This involves checking for signs of wear or damage, such as cracks, leaks, or kinks, and addressing these issues promptly. Troubleshooting common problems may involve inspecting connections for tightness, ensuring there are no obstructions in the hose, and verifying that the hose is routed correctly to avoid abrasion or excessive bending.

Environmental and Operational Considerations

Environmental factors and operational conditions can impact the performance and lifespan of the 4314220 Flexible Hose. Exposure to extreme temperatures, chemicals, or physical abrasion can lead to degradation. Mitigating these effects involves selecting the appropriate hose for the specific application, ensuring proper installation, and conducting regular maintenance to identify and address potential issues early 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and stationary applications, as well as related technologies that increase fuel efficiency and reduce emissions.

Role of Part 4314220 Flexible Hose in Engine Systems

The part 4314220 Flexible Hose is an integral component in the efficient operation of various engine systems, particularly in the context of the pump and lubricating oil subsystems.

In the pump system, the flexible hose serves as a dynamic conduit that facilitates the transfer of fluids under varying operational conditions. Its flexibility allows it to accommodate the vibrations and movements inherent in engine operation, ensuring a consistent and reliable flow of fluid from the pump to other critical components. This is particularly important in high-pressure systems where rigid hoses might fail under stress.

Within the lubricating oil system, the flexible hose plays a significant role in maintaining the integrity of the oil circulation. It connects the oil pump to the engine bearings, crankshaft, and other moving parts that require consistent lubrication. The hose’s flexibility ensures that oil is delivered smoothly, even as the engine components move and vibrate. This consistent oil flow is essential for reducing friction, minimizing wear, and ensuring the longevity of the engine components.

Additionally, the flexible nature of the hose allows for easier installation and maintenance. It can be routed around obstacles and tight spaces within the engine compartment, providing engineers and mechanics with greater flexibility in design and repair scenarios. This adaptability is particularly beneficial in compact engine designs where space is at a premium.

Overall, the part 4314220 Flexible Hose enhances the reliability and efficiency of fluid transfer in engine systems, contributing to the overall performance and durability of the engine.

Conclusion

The Cummins 4314220 Flexible Hose is a critical component in the operation of commercial trucks and various engine systems. Its design and features contribute to the efficient transfer of fluids, reduced vibration transmission, and enhanced durability. Proper installation, maintenance, and consideration of environmental factors are essential to maximizing the performance and lifespan of this part.

-

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.