This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

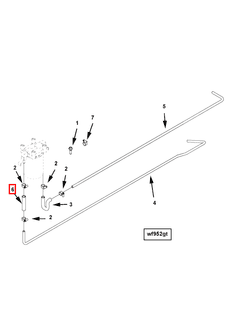

The Cummins 4095920 Flexible Hose is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, facilitating the transfer of fluids and contributing to the overall operation and efficiency of the vehicle.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in various automotive systems to connect different components, allowing for the transfer of fluids such as coolant, fuel, or hydraulic fluid. They are designed to accommodate movement and vibration, which are common in vehicle operations, thereby reducing the risk of damage to the connected systems 1.

Purpose of the Cummins 4095920 Flexible Hose

The Cummins 4095920 Flexible Hose is engineered to connect specific systems within a truck, transporting fluids that are vital for the vehicle’s operation. It plays a role in ensuring that these fluids are delivered efficiently and under the appropriate conditions, contributing to the truck’s performance and reliability 2.

Key Features

The Cummins 4095920 Flexible Hose is characterized by several key features that enhance its functionality and durability. These include its material composition, which is selected for resistance to the specific fluids it transports, as well as its flexibility and design specifications that allow it to withstand the dynamic environment of a commercial truck 3.

Benefits

Utilizing the Cummins 4095920 Flexible Hose offers several advantages. These include improved performance due to efficient fluid transfer, enhanced longevity thanks to its durable construction, and increased reliability in truck operations, which is crucial for maintaining uptime and productivity.

Installation Considerations

Proper installation of the Cummins 4095920 Flexible Hose is important for ensuring optimal performance and longevity. Guidelines and best practices should be followed to secure the hose correctly, maintain the integrity of the connections, and prevent issues such as leaks or disconnections.

Troubleshooting Common Issues

Flexible hoses, including the Cummins 4095920, may encounter issues such as leaks or wear over time. Identifying these problems early and applying appropriate troubleshooting steps can help maintain the hose’s functionality and prevent more significant system failures.

Maintenance Tips

Regular maintenance of the Cummins 4095920 Flexible Hose is recommended to prolong its life and ensure continued reliable operation. This includes adhering to inspection schedules and following care instructions to detect and address potential issues before they lead to system failures.

About Cummins

Cummins Inc. is a well-established company with a significant presence in the commercial truck industry. Its history and reputation are built on a commitment to quality and innovation, providing reliable components and systems that contribute to the efficiency and performance of commercial vehicles.

Compatibility with Engine Models

The Cummins Flexible Hose part number 4095920 is designed to integrate seamlessly with a variety of Cummins engine models, ensuring optimal performance and reliability. This part is engineered to meet the specific needs of the engines it is intended for, providing a durable and flexible connection that is crucial for various applications.

QSK23 and CM2350 Engines

The QSK23 and CM2350 engines benefit from the flexibility and strength of the 4095920 hose. These engines, known for their robust performance and efficiency, require high-quality components to maintain their operational integrity. The hose’s design allows for smooth and reliable connections, accommodating the dynamic movements and stresses inherent in these engines.

K127 Engine

The K127 engine also integrates the 4095920 Flexible Hose effectively. This engine model, recognized for its versatility and power, relies on precise and durable connections to ensure peak performance. The hose’s flexibility and resilience make it an ideal fit for the K127, providing a secure and long-lasting connection that can withstand the rigors of continuous operation.

Grouping of Engines

When considering the QSK23, CM2350, and K127 engines together, it is evident that the 4095920 Flexible Hose is a versatile component that enhances the functionality of these engines. Its design and material properties ensure that it can handle the specific demands of each engine model, providing a reliable and efficient connection that supports the overall performance of the engine.

Role of Part 4095920 Flexible Hose in Engine Systems

The part 4095920 Flexible Hose is an essential component in various engine systems, facilitating the transfer of fluids while accommodating the dynamic movements and vibrations inherent in engine operation.

Integration with Corrosion Resistors

In engine systems, the flexible hose works in conjunction with corrosion resistors to ensure the longevity and efficiency of fluid transfer pathways. Corrosion resistors are applied to metal surfaces to prevent oxidative damage, which can compromise the integrity of fluid lines. The flexible hose, by its nature, reduces stress on these resistor-coated surfaces, minimizing the risk of cracks or breaches that could lead to fluid leaks.

Mounting Considerations

The design of the flexible hose allows for easier mounting in confined engine compartments. Its flexibility enables it to navigate around other components, reducing the need for complex routing that might otherwise stress rigid hoses. This ease of installation is particularly beneficial when mounting the hose near corrosion resistor-protected areas, as it minimizes the potential for accidental damage during installation.

Enhancing System Resilience

The flexible hose’s ability to absorb vibrations and movements is particularly important in systems where resistors are used to protect against environmental factors. By reducing the transmission of vibrations to corrosion-resistant components, the hose helps maintain the effectiveness of these protective coatings over time. This interplay ensures that the engine system remains robust and reliable, even under demanding operating conditions.

Fluid Dynamics and Efficiency

Incorporating the flexible hose into engine systems also optimizes fluid dynamics. Its design allows for smooth fluid flow, reducing turbulence and pressure drops that can occur with rigid hoses. This efficiency is crucial in systems where precise fluid management is required, such as in cooling circuits protected by corrosion resistors. The hose’s flexibility ensures that fluid transfer remains consistent, even as engine components expand and contract with temperature changes.

Protective Synergies

The use of the flexible hose alongside corrosion resistors creates a synergistic effect that enhances the overall protective measures within the engine system. By accommodating movement and reducing stress on protected surfaces, the hose contributes to a more durable and efficient fluid transfer system. This collaboration between components is vital for maintaining the performance and reliability of modern engine systems.

Conclusion

The Cummins 4095920 Flexible Hose is a critical component in the operation of commercial trucks, particularly when integrated with Cummins engine models like the QSK23, CM2350, and K127. Its design and material properties ensure efficient fluid transfer, durability, and reliability, contributing to the overall performance and longevity of the engine systems it serves. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part, ensuring optimal operation and minimizing downtime.

-

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.