This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

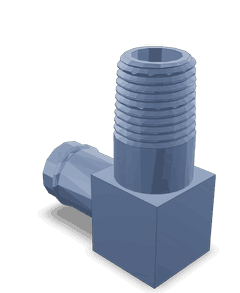

The Elbow Hose Coupling, part number 4080718, manufactured by Cummins, is a component designed for use in commercial truck systems. It plays a role in maintaining efficient fluid transfer by facilitating the connection between hoses at an angle. This Cummins part is integral to the operation of various fluid systems within trucks, including coolant, fuel, and hydraulic lines.

Basic Concepts of Elbow Hose Couplings

Elbow hose couplings are fittings that allow hoses to be connected at an angle, rather than in a straight line. This design helps in navigating the complex routing of hoses within a truck’s fluid systems. These couplings are typically constructed from durable materials such as metal or high-strength polymers to withstand the pressures and temperatures of the fluids they carry 1. Their function is to provide a secure, leak-proof connection that can accommodate movement and vibration, which are common in vehicle operations 2.

Purpose of the 4080718 Elbow Hose Coupling

The 4080718 Elbow Hose Coupling is specifically designed to connect hoses at an angle in truck systems. It facilitates smooth fluid flow by allowing hoses to bend without kinking, which can impede fluid transfer and cause stress on the hoses. This part ensures that the connection remains secure under operational conditions, contributing to the overall efficiency and reliability of the truck’s fluid systems.

Key Features

The 4080718 Elbow Hose Coupling features a design that includes precision-machined surfaces for a tight seal and durable construction materials to withstand the demands of truck operations. Its material composition may include metals for strength and polymers for flexibility and resistance to chemicals. Unique attributes such as corrosion resistance and ease of installation enhance its performance and durability 3.

Benefits

Using the 4080718 Elbow Hose Coupling in truck systems offers several advantages. It improves fluid dynamics by allowing for smooth, unrestricted flow through angled connections. The coupling’s durable construction enhances the longevity of the connection, reducing the need for frequent replacements. Additionally, its design facilitates ease of installation and maintenance, making it a practical choice for truck operators and maintenance personnel.

Installation Process

To install the 4080718 Elbow Hose Coupling, first, ensure that the hoses are clean and free of debris. Align the coupling with the hose ends, ensuring that the angled connection matches the routing required. Secure the coupling using the appropriate clamps or fasteners, following the manufacturer’s guidelines for torque specifications. Verify the connection for leaks and proper alignment before operating the vehicle 4.

Troubleshooting Common Issues

Common issues with elbow hose couplings, including the 4080718 model, may include leaks, connection failures, or hose damage. To address these problems, inspect the coupling and hoses for signs of wear or damage. Ensure that the coupling is properly aligned and secured. If leaks are present, tighten the connection or replace damaged components as necessary. Regular inspections can help identify potential issues before they lead to system failures.

Maintenance Tips

Regular maintenance of the 4080718 Elbow Hose Coupling is key to ensuring its longevity and optimal performance. Inspect the coupling and hoses for signs of wear, corrosion, or leaks during routine maintenance checks. Clean the coupling and surrounding areas to remove any buildup that could affect performance. Follow the manufacturer’s guidelines for replacement intervals to prevent failures due to wear or fatigue.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. The company’s commitment to quality and innovation is evident in its wide range of products, including the 4080718 Elbow Hose Coupling, designed to meet the demanding requirements of commercial truck systems.

Engine Compatibility with Part 4080718

The part number 4080718, an Elbow Hose Coupling manufactured by Cummins, is designed to fit seamlessly with several engine models. This part is integral to the engine’s cooling and exhaust systems, ensuring proper fluid flow and connection integrity.

Cummins 6B5.9 Engine

The 4080718 Elbow Hose Coupling is specifically engineered to integrate with the Cummins 6B5.9 engine. This part plays a role in maintaining the efficiency of the engine’s cooling system by providing a secure and leak-proof connection between hoses and the engine block. Its precision fit ensures that the engine operates within optimal temperature ranges, contributing to overall performance and longevity.

Group Compatibility

The 4080718 Elbow Hose Coupling is also compatible with a range of engines within the Cummins engine family. This part is designed to meet the stringent requirements of these engines, ensuring reliable performance across various applications. Its compatibility extends to engines that share similar design and operational parameters, providing a versatile solution for multiple engine types.

Installation and Usage

When installing the 4080718 Elbow Hose Coupling, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. This part should be used in conjunction with other Cummins-approved components to maintain the integrity of the engine’s systems. Proper installation helps prevent leaks, reduces maintenance needs, and enhances the overall reliability of the engine.

Maintenance Considerations

Regular inspection of the 4080718 Elbow Hose Coupling is recommended to ensure it remains in good condition. Any signs of wear, corrosion, or damage should be addressed promptly to prevent potential system failures. Using high-quality replacement parts and adhering to maintenance schedules will help maximize the lifespan of this component and the engine as a whole.

Role of Part 4080718 Elbow Hose Coupling in Engine Systems

The 4080718 Elbow Hose Coupling is a component in various engine systems, facilitating the efficient transfer of fluids and gases between different parts of the engine.

In the compressor air inlet system, the Elbow Hose Coupling ensures a secure and leak-free connection between the air intake and the compressor. This allows for optimal airflow into the compressor, enhancing its efficiency and performance.

Within the exhaust manifold and exhaust systems, the Elbow Hose Coupling plays a role in managing the flow of exhaust gases. It connects the exhaust manifold to the exhaust pipes, ensuring that gases are directed away from the engine compartment effectively. This not only improves engine performance but also reduces the risk of backpressure, which can negatively impact engine efficiency.

In plumbing applications, the Elbow Hose Coupling is used to connect various hoses and pipes within the engine system. Whether it’s connecting the radiator to the engine block or linking different components of the cooling system, this part ensures that coolant flows smoothly, maintaining the engine’s temperature within optimal ranges.

For the aftercooler water system, the Elbow Hose Coupling is instrumental in connecting the aftercooler to the water supply lines. This ensures that the aftercooler receives a consistent flow of water, which is essential for cooling the compressed air before it enters the engine. This process enhances the overall efficiency and reliability of the engine system.

Overall, the 4080718 Elbow Hose Coupling is a versatile component that contributes to the smooth operation of various engine systems by ensuring secure and efficient fluid and gas transfer.

Conclusion

The 4080718 Elbow Hose Coupling is a critical component in commercial truck systems, designed to facilitate efficient fluid transfer through angled connections. Its durable construction, ease of installation, and maintenance make it a practical choice for truck operators and maintenance personnel. Regular inspection and adherence to maintenance schedules are essential to ensure the longevity and optimal performance of this Cummins part.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Cummins Inc. (n.d.). QSB6.7 CM2670 B185C, Service Manual (5677064).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.