This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4071912 Flexible Hose is a component designed for use in commercial truck operations. It serves a vital role in the fluid transfer systems of trucks, ensuring efficient and reliable operation. Understanding its purpose and significance can enhance the maintenance and performance of commercial vehicles.

Basic Concepts of Flexible Hoses

Flexible hoses are components used in automotive and industrial systems to transfer fluids or gases. They are designed to accommodate movement and vibration, which are common in vehicle operations. Flexible hoses allow for the transfer of substances under varying conditions without the risk of breakage or leakage that rigid pipes might encounter. Their applications range from fuel lines to coolant systems, providing a versatile solution for fluid dynamics in automotive systems 1.

Purpose of the Cummins 4071912 Flexible Hose

The Cummins 4071912 Flexible Hose is specifically engineered to connect various systems within a truck, facilitating the transfer of fluids or gases. It plays a role in maintaining the integrity of the fluid transfer pathways, ensuring that systems operate smoothly and efficiently. This hose is integral to the overall functionality of the truck, contributing to its performance and reliability 2.

Key Features

The Cummins 4071912 Flexible Hose is characterized by several key features that enhance its performance and longevity. These include a material composition designed for durability, flexibility to accommodate movement, and design elements that ensure a secure fit and efficient fluid transfer. These features contribute to the hose’s ability to withstand the demanding conditions of commercial truck operations 3.

Benefits

The use of the Cummins 4071912 Flexible Hose offers several advantages. It contributes to improved system reliability by reducing the risk of leaks and ensuring a secure connection between components. Its flexibility allows for more efficient routing of fluids or gases, which can simplify installation and maintenance. Additionally, the durability of the hose can lead to potential cost savings over time by reducing the frequency of replacements.

Installation Considerations

Proper installation of the Cummins 4071912 Flexible Hose is crucial for its effective performance. Best practices include ensuring a secure fit without over-tightening, which can damage the hose, and verifying compatibility with other system components. Common pitfalls to avoid include improper alignment and failure to inspect the hose for damage prior to installation. Adhering to these guidelines can enhance the hose’s performance and longevity.

Troubleshooting and Maintenance

Regular inspection and maintenance of the Cummins 4071912 Flexible Hose can help identify common issues such as leaks, kinks, or signs of degradation. Recommended practices include periodic checks for wear and tear, ensuring connections remain secure, and replacing the hose if any damage is detected. These practices contribute to the optimal performance and longevity of the hose.

Safety Considerations

When working with flexible hoses, including the Cummins 4071912, it is important to follow safety protocols. This includes proper handling to avoid damage, conducting thorough inspections for wear or leaks, and adhering to replacement guidelines to prevent accidents or system failures. Safety considerations are paramount in ensuring the reliable operation of commercial trucks.

Environmental Impact

The use and disposal of flexible hoses, including the Cummins 4071912, have environmental considerations. The recyclability of materials and the importance of proper waste management practices are key factors in minimizing the environmental impact. Responsible disposal and recycling can contribute to sustainable practices in the commercial truck industry.

Cummins Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial truck markets globally. The company’s product range includes a variety of components designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Compatibility with K19, K38, and K50 Engines

The Cummins Flexible Hose 4071912 is designed to integrate seamlessly with a range of Cummins engines, including the K19, K38, and K50 series. This hose is engineered to provide flexibility and durability, ensuring optimal performance and longevity in various engine applications.

K19 and K38 Engines

For the K19 and K38 engines, the 4071912 Flexible Hose is a critical component that connects different parts of the engine’s cooling system. Its design allows for movement and flexibility, accommodating the natural shifts and vibrations that occur during engine operation. This flexibility helps to prevent stress on the hose, reducing the risk of leaks and ensuring a reliable seal.

K50 Engine

In the K50 engine, the 4071912 Flexible Hose serves a similar purpose, providing a crucial link in the engine’s fuel or coolant systems. The hose’s ability to flex and move with the engine ensures that connections remain secure and that the system operates efficiently. This is particularly important in the K50, where precise and reliable connections are essential for maintaining engine performance.

Grouping for Efficiency

When considering the K19, K38, and K50 engines together, the 4071912 Flexible Hose demonstrates its versatility and importance across different engine models. Its design is optimized to fit the specific requirements of each engine series, ensuring that it performs effectively in various operating conditions. This makes the hose a valuable component for maintaining the integrity and efficiency of these engines.

Role of Part 4071912 Flexible Hose in Engine Systems

Part 4071912 Flexible Hose is an integral component in various engine systems, facilitating the efficient transfer of fluids under dynamic conditions. Its application spans across several key components, enhancing the overall performance and reliability of the engine.

Fuel System

In the fuel system, the Flexible Hose connects the fuel tank to the fuel pump and other accessories. This connection ensures a consistent fuel supply to the engine, accommodating movements and vibrations that occur during operation. The flexibility of the hose prevents stress on the connections, reducing the risk of leaks and ensuring a stable fuel flow.

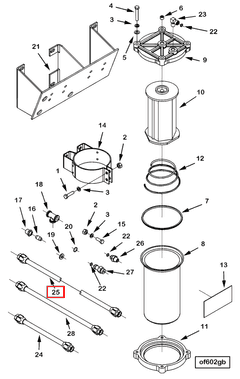

Oil Bypass Filter System

Within the oil bypass filter system, the Flexible Hose plays a significant role in routing oil from the engine to the bypass filter. This setup allows for the filtration of contaminants while maintaining oil flow, even if the primary filter becomes restricted. The hose’s flexibility accommodates the engine’s movements, ensuring uninterrupted oil circulation and protecting the engine from wear.

Bypass Filter Mounting

For bypass filter mounting configurations, the Flexible Hose is used to connect the filter to the engine and other components. This application ensures that the filter can be efficiently integrated into the engine’s oil system, providing an additional layer of filtration without compromising the oil flow. The hose’s design allows for easy installation and maintenance, enhancing the system’s overall efficiency.

Super Bypass Filter and Mounting

In super bypass filter systems, the Flexible Hose is essential for connecting the super bypass filter to the engine and other components. This connection ensures that the filter can effectively manage oil flow, providing enhanced filtration capabilities. The hose’s flexibility accommodates the dynamic environment of the engine, ensuring reliable performance.

Lubricating Oil Filter System

The Flexible Hose is also utilized in lubricating oil filter systems, connecting the filter to the engine and other components. This application ensures that the filter can efficiently manage oil flow, providing clean lubrication to critical engine parts. The hose’s design allows for easy integration into the engine’s lubrication system, enhancing overall engine health.

Spares Kit

In spares kits, the Flexible Hose is included as a replacement part for various engine systems. Its versatility allows it to be used in multiple applications, ensuring that engineers and mechanics have a reliable component on hand for maintenance and repairs. The hose’s durability and flexibility make it a valuable addition to any spares kit, providing peace of mind during engine servicing.

Filter Lo Bypass and MTG Superbypass Filter

For filter lo bypass and MTG superbypass filter applications, the Flexible Hose ensures efficient oil flow and filtration. Its role in these systems is to provide a reliable connection between the filter and the engine, accommodating the dynamic conditions of the engine environment. The hose’s flexibility and durability make it an essential component in these advanced filtration systems.

Conclusion

The Cummins 4071912 Flexible Hose is a critical component in the fluid transfer systems of commercial trucks, offering durability, flexibility, and efficient performance. Its compatibility with various Cummins engines, including the K19, K38, and K50 series, underscores its versatility and importance. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the hose’s performance and longevity, contributing to the overall reliability and efficiency of commercial vehicles.

-

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.