This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4071906 Flexible Hose Assembly is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, facilitating the transfer of fluids between various parts of the vehicle. Understanding its purpose and role is fundamental for maintaining the efficiency and reliability of truck operations.

Basic Concepts of Flexible Hose Assemblies

Flexible hose assemblies are components used in automotive systems to connect different parts that require fluid transfer. These assemblies are designed to accommodate movement and vibration, which are common in vehicle operations. They are typically used in fuel, coolant, and brake systems, among others, to ensure a secure and leak-free connection between components 1.

Purpose of the 4071906 Flexible Hose Assembly

The Cummins 4071906 Flexible Hose Assembly is engineered to connect specific systems within a truck, transporting fluids essential for the vehicle’s operation. It plays a role in maintaining the integrity of the fluid transfer process by providing a flexible yet durable connection that can withstand the dynamic environment of a commercial truck.

Key Features

The 4071906 Flexible Hose Assembly boasts several key features that enhance its performance. These include a material composition designed for durability and flexibility, allowing it to withstand high temperatures and pressures. Its design incorporates elements that ensure a secure fit and easy installation, along with unique characteristics that improve its overall effectiveness in demanding conditions.

Benefits

The benefits of the 4071906 Flexible Hose Assembly include improved flexibility, which accommodates the movement and vibration inherent in truck operations. Its durability ensures long-term reliability, while its resistance to high temperatures and pressures makes it suitable for the demanding environments typical of commercial trucks. Overall, it contributes to the efficient and reliable operation of the truck’s systems.

Installation Considerations

When installing the 4071906 Flexible Hose Assembly, it is important to follow guidelines and best practices to ensure proper fitting and securing. This includes verifying compatibility with the existing truck systems to prevent issues such as leaks or connection failures. Careful attention to these details during installation can enhance the assembly’s performance and longevity.

Troubleshooting Common Issues

Common problems that may arise with the 4071906 Flexible Hose Assembly include leaks, wear and tear, and connection failures. Troubleshooting these issues involves inspecting the assembly for signs of damage, ensuring all connections are secure, and replacing the assembly if necessary. Regular checks can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 4071906 Flexible Hose Assembly, regular maintenance practices are recommended. This includes routine inspections for signs of wear or damage, cleaning the assembly to remove any debris that could affect its operation, and following manufacturer guidelines for replacement. These practices help maintain the assembly’s effectiveness and contribute to the overall reliability of the truck’s systems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. Its commitment to excellence is reflected in the design and performance of components like the 4071906 Flexible Hose Assembly 2.

Role of the 4071906 Flexible Hose Assembly in Engine Systems

The 4071906 Flexible Hose Assembly is integral to the efficient operation of various engine systems by providing a reliable and adaptable connection between components.

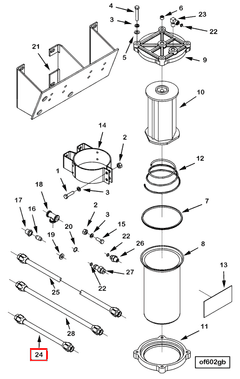

Oil System Integration

In the oil system, the Flexible Hose Assembly is employed to connect the oil bypass filter to the main oil lines. This setup allows for the filtration of oil while enabling the bypass of excess flow to maintain consistent oil pressure. The hose’s flexibility accommodates the movement and vibrations inherent in engine operation, ensuring a secure and durable connection.

Fuel System Application

Within the fuel system, the Flexible Hose Assembly plays a significant role in the fuel supply plumbing. It connects the fuel pump coupling to the fuel injectors or carburetor, facilitating the delivery of fuel under varying engine loads and conditions. The hose’s flexibility is particularly beneficial in this application, as it absorbs the dynamic stresses and thermal expansions that occur during engine operation.

Super Bypass Filter Arrangement

The Flexible Hose Assembly is also utilized in the arrangement of the super bypass filter (often abbreviated as mtg superbypass filter). This filter is designed to handle higher flow rates and provide additional filtration capacity. The hose ensures a robust connection between the filter and the oil system, accommodating the increased flow and pressure without compromising integrity.

General Plumbing and Mounting

Across various engine systems, the Flexible Hose Assembly is a versatile component in the overall plumbing and mounting strategies. Its use extends to connecting different filters, sensors, and actuators to their respective systems. The hose’s design allows for easy installation and maintenance, reducing the complexity of engine arrangements and enhancing overall system reliability.

Conclusion

The Cummins 4071906 Flexible Hose Assembly is a critical component in the maintenance and operation of commercial trucks. Its design and features ensure reliable fluid transfer across various engine systems, contributing to the overall efficiency and reliability of truck operations. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.