This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4067909 Flexible Hose is a component designed for use in commercial trucks. It facilitates the transfer of fluids between various parts of the vehicle, engineered to withstand the demanding conditions typical of commercial truck operations, ensuring reliable performance and longevity.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive applications to connect different parts of a system that may move or vibrate relative to each other. They are designed to accommodate movement while maintaining a secure and leak-free connection. In a truck, flexible hoses transport fluids such as coolant, fuel, or hydraulic fluid, contributing to the overall efficiency and functionality of the vehicle 1.

Purpose of the 4067909 Flexible Hose

This Cummins part is designed to connect specific systems within a truck, allowing for the transport of fluids between these systems. It is integral to maintaining the operational integrity of the truck by ensuring that fluids are delivered where needed without leakage or disruption. This hose is typically used in applications where rigid pipes cannot accommodate the movement or vibration inherent in truck operations.

Key Features

The 4067909 boasts several key features that enhance its performance and durability. It is constructed from materials that offer resistance to wear and tear, as well as flexibility to accommodate the dynamic movements of a commercial truck. The design specifications of this hose ensure it can withstand high pressure and temperature variations, making it suitable for a wide range of operating conditions 2.

Benefits of Using the 4067909 Flexible Hose

Utilizing this part provides several advantages. Its flexibility allows for greater movement and vibration absorption, reducing the risk of damage to the hose or connected systems. The hose’s durability ensures long-term reliability, even under harsh operating conditions. Additionally, its design contributes to improved performance and efficiency within the truck’s systems.

Installation Considerations

When installing the 4067909, it is important to follow guidelines and best practices to ensure proper fitting and secure connections. This includes verifying compatibility with existing systems, using appropriate securing methods, and ensuring all connections are tight and leak-free. Proper installation is key to maximizing the hose’s performance and lifespan.

Troubleshooting Common Issues

Common problems associated with flexible hoses include leaks, kinks, or degradation over time. To address these issues, it is important to regularly inspect the hose for signs of wear or damage. If a leak is detected, the source should be identified and repaired or replaced as necessary. Kinks can often be resolved by repositioning the hose, while degradation may require replacement of the hose to ensure continued reliable operation.

Maintenance Tips

To prolong the lifespan of the 4067909, routine maintenance practices are recommended. This includes regular inspection intervals to check for signs of wear, damage, or leaks. Cleaning the hose as part of routine maintenance can also help prevent buildup that may lead to performance issues. Replacement guidelines should be followed when the hose shows significant signs of wear or failure.

Safety Precautions

When working with the 4067909, observing safety measures is crucial. This includes using proper handling techniques to avoid damage to the hose, wearing protective equipment to safeguard against potential hazards, and having emergency procedures in place in case of hose failure. Safety should always be a priority when performing maintenance or repairs on any vehicle component.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product offerings are designed to meet the diverse needs of its customers, ensuring reliable and efficient performance in various applications.

Cummins Flexible Hose 4067909 Compatibility

The Cummins Flexible Hose part number 4067909 is designed to integrate seamlessly with a variety of engine models, ensuring reliable performance and durability. This hose is engineered to withstand the rigors of engine operation, providing a flexible connection that can accommodate movement and reduce stress on the engine components.

QST30 Engines

For the QST30 engines, the Flexible Hose 4067909 is a critical component that connects various fluid systems, ensuring smooth operation and preventing leaks. Its flexibility allows it to adapt to the engine’s movements, reducing wear and tear on the connections.

CM552 Engines

In the CM552 engines, the Flexible Hose 4067909 is used to link the engine’s fuel and coolant systems, providing a robust and leak-proof connection. This hose is essential for maintaining the engine’s efficiency and longevity, as it helps to prevent fluid loss and system contamination.

Grouped Engine Compatibility

The Cummins Flexible Hose 4067909 is compatible with a range of engine models, including but not limited to, the QST30 and CM552 engines. This hose is designed to fit snugly and securely, ensuring that it can handle the demands of high-performance engines. Its flexibility and durability make it an ideal choice for maintaining the integrity of the engine’s fluid systems.

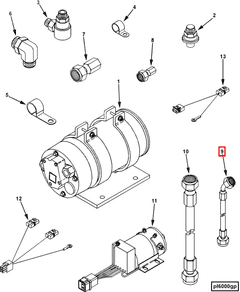

Role of Part 4067909 Flexible Hose in Engine Systems

The 4067909 Flexible Hose is integral to several engine system components, facilitating efficient operation and maintenance.

In the Kit component, the flexible hose allows for the connection of various parts, ensuring a secure and leak-free system. This is particularly important during the assembly and disassembly phases, where rigid hoses might cause complications.

For the Prelub Plumb Remote system, the hose provides the necessary flexibility to route lubricants to remote parts of the engine that require pre-lubrication. This ensures that all components are adequately lubricated before the engine starts, reducing wear and tear.

In the context of Prechamber-Lubricating Plumbing, the flexible hose plays a significant role in delivering lubricant to the prechambers. This is essential for maintaining the integrity and performance of the prechambers, which are vital for combustion efficiency.

The Primer system benefits from the use of the 4067909 Flexible Hose by allowing for easier and more effective priming of the engine. The hose’s flexibility ensures that primer fluid can reach all necessary points without the risk of leaks or blockages.

Lastly, in the Engine Lubricating system, the hose ensures a consistent flow of lubricant to various engine components. This is essential for reducing friction, cooling moving parts, and prolonging the engine’s lifespan.

Overall, the 4067909 Flexible Hose enhances the functionality and reliability of these engine systems by providing a flexible, durable, and leak-resistant connection solution 3.

Conclusion

The Cummins 4067909 Flexible Hose is a critical component in the operation and maintenance of commercial trucks and their engines. Its design, featuring flexibility, durability, and resistance to high pressure and temperature variations, ensures reliable performance under demanding conditions. Proper installation, regular maintenance, and adherence to safety precautions are essential for maximizing the lifespan and efficiency of this part. Its compatibility with various engine models and its role in multiple engine systems underscore its importance in ensuring the smooth and efficient operation of commercial vehicles.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.