This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

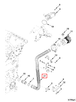

The 4015476 Molded Hose is a component manufactured by Cummins, a well-established name in the commercial truck industry. This hose is significant in commercial truck operations due to its role in ensuring the efficient transfer of fluids within the truck’s systems. Understanding its function, construction, and maintenance is vital for maintaining the overall performance and reliability of commercial trucks.

Basic Concepts of Molded Hoses

Molded hoses are specialized components designed to transport fluids within a vehicle’s system. They are constructed using a combination of synthetic rubber and reinforcement materials, which provide flexibility and strength. These hoses are molded into specific shapes to fit precisely within the vehicle’s system, reducing the risk of leaks and improving overall efficiency. Their function is to facilitate the smooth and reliable transfer of fluids, such as coolant, fuel, or hydraulic fluid, between different parts of the vehicle 1.

Purpose of the 4015476 Molded Hose

This Cummins part plays a role in the operation of a truck by connecting various systems and transporting specific fluids. It is designed to link critical components within the truck’s system, ensuring that fluids are delivered where needed without leakage or contamination. This hose is integral to maintaining the truck’s operational efficiency and reliability.

Key Features

The 4015476 Molded Hose incorporates several design elements and materials that enhance its performance and durability. It is constructed using high-quality synthetic rubber for flexibility and resistance to environmental factors. The hose also features reinforcement materials that provide additional strength and durability. These design elements ensure that the hose can withstand the rigors of commercial truck operations while maintaining its integrity and functionality.

Benefits

This part offers several advantages, including improved reliability, resistance to environmental factors, and ease of installation. Its precise molding ensures a snug fit within the truck’s system, reducing the risk of leaks. The materials used in its construction provide resistance to heat, chemicals, and physical stress, enhancing its durability. Additionally, the hose’s design allows for straightforward installation, minimizing downtime during maintenance procedures.

Installation Process

Proper installation of this Cummins part is crucial for ensuring optimal performance and longevity. The installation process involves several steps: first, ensuring that the area where the hose will be installed is clean and free of debris. Next, the hose should be carefully positioned to align with the connection points. It is then secured in place using the appropriate clamps or fasteners. Finally, the system should be tested to ensure there are no leaks and that the hose is functioning correctly.

Common Issues and Troubleshooting

Typical problems that may arise with molded hoses include leaks, cracks, or blockages. These issues can often be identified through regular inspections and maintenance. Troubleshooting steps may involve checking for proper installation, inspecting the hose for signs of wear or damage, and ensuring that all connections are secure. In some cases, replacing the hose may be necessary to resolve persistent issues.

Maintenance Tips

Regular maintenance practices can help prolong the life of the 4015476 Molded Hose. This includes conducting routine inspections to check for signs of wear, damage, or leaks. It is also important to ensure that all connections are secure and that the hose is properly supported within the truck’s system. Following the manufacturer’s recommendations for inspection intervals and care instructions can help maintain the hose’s performance and durability.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. Founded in 1919, Cummins has a long history of innovation and excellence in engine and power generation technologies. The company offers a comprehensive product range, including engines, filtration systems, and aftermarket parts, designed to meet the demanding needs of commercial truck operations. Cummins’ commitment to quality and customer satisfaction has established it as a trusted name in the industry 2.

Role of Part 4015476 Molded Hose in Engine Systems

In the context of engine systems, the 4015476 molded hose is integral to the efficient operation of several components.

Arrangement

The molded hose is often utilized within the arrangement of various engine components to facilitate the smooth transfer of fluids and gases. Its design allows for a secure and leak-free connection between different parts, ensuring that the engine operates within optimal parameters. This is particularly important in high-performance engines where precision and reliability are paramount 3.

Crankcase Breather

In the crankcase breather system, the molded hose plays a significant role by allowing the release of pressure built up within the crankcase. This is essential for maintaining the integrity of the engine’s internal components. The hose connects to the breather valve, enabling the expulsion of contaminants and moisture that accumulate during engine operation. This helps in preserving the cleanliness of the crankcase and prolonging the life of the engine oil.

The molded hose’s durability and resistance to various engine-related stresses make it an invaluable component in ensuring the crankcase breather system functions effectively.

Conclusion

The 4015476 Molded Hose is a critical component in the operation of commercial trucks, particularly in the context of Cummins engines. Its design, construction, and role in fluid management contribute significantly to the efficiency, reliability, and longevity of these engines. Regular maintenance and proper installation are essential to ensure the optimal performance of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.