This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

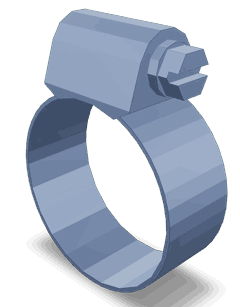

The Hose Clamp 4014593, manufactured by Cummins, is a vital component in the commercial truck industry. This part ensures secure connections and reliable performance in various truck systems, contributing to the overall functionality and safety of commercial trucks.

Basic Concepts of Hose Clamps

Hose clamps are devices used to secure hoses to fittings, ensuring a tight and leak-free connection. They are commonly employed in automotive and industrial applications to maintain the flow of fluids such as coolant, fuel, and air. Hose clamps are typically constructed from materials like stainless steel, spring steel, or various polymers, chosen for their durability, resistance to corrosion, and ability to withstand high temperatures and pressures 1.

Purpose of Hose Clamp 4014593

The Hose Clamp 4014593 is designed to play a specific role in the operation of commercial trucks. It is utilized in various truck systems, including the cooling system, fuel lines, and pneumatic systems. By securing hoses in these systems, the clamp ensures that fluids and gases are transported efficiently and without leakage, which is vital for the truck’s performance and safety 2.

Key Features

The Hose Clamp 4014593 features a robust design that enhances its functionality. It is typically made from high-quality materials that offer resistance to corrosion and wear. The clamp’s design allows for easy installation and removal, and it includes features such as a serrated edge to grip the hose firmly and a tensioning mechanism to ensure a secure fit.

Benefits

Using the Hose Clamp 4014593 provides several advantages. Its reliable design contributes to the overall durability of hose connections, reducing the risk of leaks and failures. The ease of installation and removal simplifies maintenance procedures, allowing for quick repairs and replacements when necessary. Additionally, the clamp’s construction materials and design features contribute to its longevity, offering cost-effective solutions for truck operators 3.

Installation Process

Installing the Hose Clamp 4014593 involves several steps to ensure a secure and proper fit. Begin by cleaning the hose and fitting to remove any debris or contaminants. Slide the clamp onto the hose, ensuring it is positioned correctly. Use a wrench or clamp tool to tighten the clamp gradually, ensuring even pressure distribution. Check for leaks by pressurizing the system and inspecting the connection. Avoid over-tightening, which can damage the hose.

Troubleshooting Common Issues

Frequent problems with hose clamps include leaks, loose connections, and corrosion. To diagnose these issues, inspect the clamp and hose for signs of wear, damage, or misalignment. If a leak is detected, check the clamp’s tension and ensure it is properly seated. Loose connections may require re-tightening or replacement of the clamp. Corrosion can be addressed by replacing the affected components with corrosion-resistant materials.

Maintenance Tips

Regular maintenance of the Hose Clamp 4014593 is crucial for its longevity and effectiveness. Inspect the clamp and hose connections periodically for signs of wear, corrosion, or leaks. Clean the clamp and hose to remove any buildup of dirt or debris. Replace the clamp if it shows signs of significant wear or damage. Following these maintenance practices will help ensure the reliable operation of the truck’s systems.

Safety Considerations

When installing, maintaining, or replacing the Hose Clamp 4014593, it is important to follow safety protocols to prevent accidents and ensure compliance with industry standards. Use appropriate personal protective equipment (PPE) such as gloves and safety glasses. Ensure the truck’s engine is off and the system is depressurized before beginning work. Follow manufacturer guidelines for torque specifications to avoid over-tightening, which can damage the hose and fitting.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial truck operations.

Cummins Hose Clamp 4014593 Compatibility

The Cummins Hose Clamp part number 4014593 is designed to fit seamlessly with various engine models, ensuring a secure and reliable connection for hoses. This clamp is engineered to maintain the integrity of the engine’s cooling and fuel systems by preventing leaks and ensuring that hoses remain firmly attached to their respective fittings.

Engine Compatibility

- QSV91G

This hose clamp is specifically engineered to fit the QSV91G engine, providing a critical function in maintaining the engine’s operational efficiency. Its design ensures that hoses are securely fastened, which is essential for the proper functioning of the engine’s systems.

Grouping of Engines

While the Cummins Hose Clamp 4014593 is primarily designed to fit the QSV91G engine, it is also compatible with other engines within the same family or those that share similar design specifications. This compatibility ensures that the clamp can be used across multiple engine models, providing a versatile solution for engine maintenance and repair.

Role of Part 4014593 Hose Clamp in Engine Systems

The part 4014593 Hose Clamp is instrumental in maintaining the integrity and efficiency of various engine systems. In the context of the arrangement of engine components, this hose clamp ensures that hoses remain securely fastened to their respective fittings. This is particularly important in dynamic engine environments where vibrations and movements could otherwise dislodge hoses, leading to leaks or failures in fluid transfer systems.

In the crankcase breather system, the hose clamp plays a significant role by securing the hoses that vent pressure from the crankcase. This system is designed to release built-up gases and moisture from the crankcase, which if not properly managed, could lead to contamination of the engine oil and reduced engine performance. The hose clamp ensures that the breather hoses remain firmly attached, allowing for effective pressure release and maintaining the cleanliness of the engine oil.

Additionally, the hose clamp is utilized in cooling systems where it secures radiator hoses. This ensures a consistent flow of coolant through the engine, preventing overheating and maintaining optimal engine temperature. The reliability of the hose clamp in these systems is paramount, as any failure in the cooling system can lead to severe engine damage.

Furthermore, in fuel systems, the hose clamp is employed to secure fuel lines, ensuring a steady and leak-free supply of fuel to the engine. This is essential for maintaining engine performance and efficiency, as any disruption in fuel delivery can result in engine misfires or stalls.

Overall, the part 4014593 Hose Clamp is a fundamental component in various engine systems, providing the necessary security and reliability for hoses in critical applications.

Conclusion

The Hose Clamp 4014593 by Cummins is a critical component in ensuring the reliable operation of commercial truck systems. Its robust design, ease of installation, and compatibility with various engine models make it a versatile and essential part for maintaining the integrity of hose connections in cooling, fuel, and pneumatic systems. Regular maintenance and adherence to safety protocols are essential for maximizing the lifespan and effectiveness of this Cummins part.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ -

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.