This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4001415 Flexible Hose is a component designed for use in commercial truck systems. It serves as a conduit for various fluids, facilitating their movement between different parts of the truck’s system. This part is integral to maintaining the efficiency and reliability of the truck’s operations.

Basic Concepts of Flexible Hoses

Flexible hoses are tubes made from materials that allow them to bend and flex without breaking. They are commonly used in automotive and industrial applications to transport fluids such as coolant, fuel, and hydraulic fluid. Flexible hoses are preferred over rigid pipes in situations where movement or vibration is expected, as they can accommodate these motions without compromising the flow of fluids 1.

Purpose of the 4001415 Flexible Hose

The Cummins 4001415 Flexible Hose is specifically designed to connect various systems within a commercial truck, such as the engine cooling system or the fuel system. It transports fluids between these systems, ensuring that they operate correctly. The hose’s flexibility allows it to withstand the vibrations and movements typical in a truck’s operating environment 2.

Key Features

The Cummins 4001415 Flexible Hose boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that provide resistance to wear and tear, as well as to the chemicals found in the fluids it transports. The hose’s design includes reinforced ends to ensure a secure fit with the connections it interfaces with, and its flexibility allows it to bend and twist without kinking or breaking 3.

Benefits

Using the Cummins 4001415 Flexible Hose offers several advantages. Its flexibility reduces the risk of damage from vibrations and movements, which are common in commercial truck operations. The hose’s durable construction ensures it can withstand the harsh conditions often encountered in these environments. Additionally, its design allows for easier installation and maintenance, contributing to the overall efficiency of the truck’s system 4.

Installation Considerations

When installing the Cummins 4001415 Flexible Hose, it is important to follow guidelines to ensure a proper fit and secure connection. This includes using the correct fittings and securing methods to prevent leaks and ensure the hose remains in place. Compatibility with the existing system should also be verified to ensure optimal performance 5.

Troubleshooting Common Issues

Common issues with flexible hoses include leaks, kinks, and degradation over time. To address these problems, regular inspections should be conducted to identify any signs of wear or damage. If a leak is detected, the hose should be replaced or repaired as necessary. Kinks can often be resolved by repositioning the hose, and degradation may require replacement depending on the extent of the damage 6.

Maintenance Tips

To ensure the longevity and reliable performance of the Cummins 4001415 Flexible Hose, regular maintenance is recommended. This includes periodic inspections to check for signs of wear, damage, or leaks. Replacement guidelines should be followed to ensure that the hose is replaced before it fails, maintaining the efficiency and safety of the truck’s system 7.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name in the industry 8.

Cummins Engine Part 4001415: Flexible Hose Compatibility

The Cummins part 4001415, a Flexible Hose, is designed to integrate seamlessly with a range of Cummins engines, ensuring efficient fluid transfer and system integrity. This part is particularly compatible with the following engines:

- QSK60 CM500

The QSK60 CM500 engine is known for its robust performance and reliability, often used in heavy-duty applications. The Flexible Hose part 4001415 is engineered to fit precisely within the engine’s fluid systems, providing a durable and flexible connection that can withstand the rigors of demanding environments.

Integration with Cummins Engines

The Flexible Hose part 4001415 is meticulously designed to ensure compatibility with the QSK60 CM500 engine. Its flexibility and durability make it an ideal component for managing the dynamic stresses encountered in heavy-duty operations. The hose’s design allows for smooth fluid transfer, reducing the risk of leaks and ensuring the engine operates at peak efficiency.

Application Considerations

When integrating the Flexible Hose part 4001415 into the QSK60 CM500 engine, it is crucial to consider the following:

- Pressure Ratings: Ensure the hose can handle the specific pressure requirements of the engine’s fluid systems.

- Temperature Resistance: Verify that the hose material can withstand the operational temperatures of the engine.

- Connection Integrity: Confirm that the hose fits securely with the engine’s connectors, minimizing the risk of disconnections.

By adhering to these considerations, the Flexible Hose part 4001415 can be effectively integrated into the QSK60 CM500 engine, enhancing its performance and reliability.

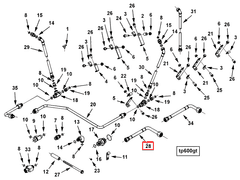

Role of Part 4001415 Flexible Hose in Plumbing and Turbocharger Coolant Systems

Plumbing Systems

In plumbing systems, the 4001415 Flexible Hose is instrumental in connecting various components that facilitate the flow of fluids. It is often used to link pipes, valves, and fixtures, ensuring a secure and leak-free connection. The flexibility of the hose allows it to accommodate minor misalignments and vibrations, which are common in dynamic plumbing environments. This adaptability helps maintain consistent fluid flow, reducing the risk of leaks and system failures. Additionally, the hose’s material is typically resistant to corrosion and high pressure, making it suitable for both residential and industrial plumbing applications 9.

Turbocharger Coolant Systems

In turbocharger coolant systems, the 4001415 Flexible Hose plays a significant role in managing the flow of coolant to and from the turbocharger. The turbocharger generates a substantial amount of heat during operation, and efficient coolant circulation is essential to maintain optimal performance and prevent overheating. The flexible nature of the hose allows it to route around complex engine compartments, ensuring a direct and unobstructed path for the coolant. This helps in dissipating heat effectively, thereby enhancing the turbocharger’s efficiency and longevity. Furthermore, the hose’s durability under high temperatures and pressures ensures reliable operation in demanding engine environments 10.

Conclusion

The Cummins 4001415 Flexible Hose is a critical component in commercial truck systems, offering flexibility, durability, and efficient fluid transfer. Its compatibility with various Cummins engines, including the QSK60 CM500, ensures seamless integration and enhanced performance. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall reliability and efficiency of the truck’s systems.

-

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSK78 CM2250 K104. Bulletin Number 4332684.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSK78 CM2250 K104. Bulletin Number 4332684.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.