Introduction

The Cummins 3955171 Plain Hose Coupling is a component designed for use in commercial trucks. It serves a specific function within the fluid transfer systems of these vehicles, facilitating the connection between hoses and other components to ensure efficient and reliable fluid transfer.

Basic Concepts of Plain Hose Couplings

Plain hose couplings are devices used to connect hoses to fittings or other hoses in fluid transfer systems. They operate by providing a secure, leak-proof connection that allows fluids to pass through without interruption. These couplings are commonly used in various applications, including automotive, industrial, and agricultural systems, where reliable fluid transfer is necessary 2.

Purpose of the Cummins 3955171 Plain Hose Coupling

The Cummins 3955171 Plain Hose Coupling plays a role in the fluid transfer system of a truck by connecting hoses to other components, such as pumps or reservoirs. This connection ensures that fluids, such as coolant or hydraulic fluid, can be transferred efficiently and without leaks. The coupling’s design allows for easy connection and disconnection, facilitating maintenance and repairs 3.

Key Features

The Cummins 3955171 Plain Hose Coupling is constructed from durable materials, ensuring it can withstand the pressures and temperatures encountered in commercial truck applications. Its design includes features that enhance its performance, such as a robust clamp mechanism that secures the hose in place and prevents leaks. Additionally, the coupling is designed for ease of use, allowing for quick and simple installation and removal 4.

Benefits

The Cummins 3955171 Plain Hose Coupling offers several advantages, including durability, ease of installation, and reliability in various operating conditions. Its robust construction ensures it can withstand the rigors of commercial truck use, while its design allows for quick and simple installation, reducing downtime during maintenance. The coupling’s reliable performance helps ensure the efficient operation of the truck’s fluid transfer system 1.

Installation Process

Installing the Cummins 3955171 Plain Hose Coupling involves several steps to ensure a secure and leak-proof connection. First, the hose should be prepared by cleaning the end that will be connected to the coupling. Next, the coupling should be positioned over the hose end, and the clamp mechanism should be tightened to secure the connection. It is important to follow the manufacturer’s instructions for proper installation to ensure the coupling functions correctly 2.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3955171 Plain Hose Coupling, regular maintenance is recommended. This includes inspecting the coupling for signs of wear or damage, such as cracks or leaks, and cleaning it as necessary to remove any buildup that could affect its performance. Additionally, ensuring that the clamp mechanism is properly tightened can help prevent leaks and maintain a secure connection 3.

Troubleshooting Common Issues

Common issues that may arise with the Cummins 3955171 Plain Hose Coupling include leaks, difficulty in installation or removal, and damage to the coupling or hose. To address these issues, it is important to inspect the coupling and hose for signs of wear or damage, ensure that the clamp mechanism is properly tightened, and replace any damaged components as necessary. Following the manufacturer’s instructions for installation and maintenance can help prevent these issues from occurring 4.

Compatibility and Applications

The Cummins 3955171 Plain Hose Coupling is designed for use in various truck models and systems, highlighting its versatility. It is compatible with a range of hose sizes and types, making it suitable for use in different fluid transfer applications within the commercial truck industry 1.

Safety Considerations

When working with the Cummins 3955171 Plain Hose Coupling, it is important to observe several safety guidelines and precautions. This includes ensuring that the coupling is properly installed and secured to prevent leaks, using the appropriate tools and equipment for installation and maintenance, and following the manufacturer’s instructions for safe operation. Additionally, personnel should be trained in the proper handling and maintenance of the coupling to ensure the safety of both the equipment and the individuals working with it 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of its customers, from engines and powertrains to aftermarket parts and services 3.

Cummins Engine Compatibility with Part 3955171

The Plain Hose Coupling part number 3955171, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s cooling and exhaust systems, ensuring proper sealing and connection of hoses. Below is a detailed breakdown of the engines that are compatible with this part:

ISB Series Engines

- ISB CM2150

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

The ISB series engines, including both the 4.5L and 6.7L variants, are designed for heavy-duty applications. The Plain Hose Coupling part 3955171 is compatible with these engines, ensuring a secure and leak-proof connection for the hoses involved in the engine’s cooling and exhaust systems 4.

QSB Series Engines

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The QSB series engines, ranging from 4.5L to 7L, are built for both on-highway and off-highway applications. The Plain Hose Coupling part 3955171 is engineered to fit these engines, providing a reliable connection for the hoses that are critical to the engine’s operation 1.

B Series Engines

- B6.7 CM2350 B135B

- B6.7 CM2670 B164C

The B series engines, specifically the 6.7L variants, are designed for heavy-duty applications. The Plain Hose Coupling part 3955171 is compatible with these engines, ensuring that the hoses are securely connected, which is vital for maintaining the engine’s performance and efficiency 2.

ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines, including both the 4.5L and 6.7L variants, are built for heavy-duty applications. The Plain Hose Coupling part 3955171 is designed to fit these engines, providing a secure and leak-proof connection for the hoses involved in the engine’s cooling and exhaust systems 3.

By ensuring compatibility with a wide range of Cummins engines, the Plain Hose Coupling part 3955171 plays a crucial role in maintaining the integrity and performance of the engine’s systems.

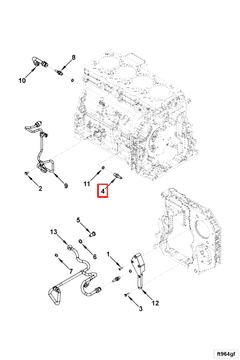

Role of Part 3955171 Plain Hose Coupling in Engine Systems

The Part 3955171 Plain Hose Coupling is instrumental in ensuring the seamless integration and operation of various engine components. Its primary function is to facilitate secure and leak-proof connections between hoses and fittings, which is essential for the efficient functioning of the engine system.

In the context of the crankcase breather system, the Plain Hose Coupling ensures that the hoses connecting the breather to the intake manifold or atmosphere are firmly attached. This connection allows for the proper ventilation of gases from the crankcase, preventing pressure build-up and maintaining optimal engine performance 4.

When it comes to the drain location components, such as oil pans or fuel tanks, the Plain Hose Coupling is used to connect drain hoses securely. This ensures that fluids can be efficiently and safely drained without any risk of spills or leaks, which is vital for maintenance procedures and overall engine health 1.

In systems involving an electronic control cooler, the Plain Hose Coupling plays a role in connecting the cooler to the fluid lines. This secure connection is necessary to maintain the integrity of the cooling system, ensuring that the electronic control units receive consistent and reliable cooling, which is essential for their operation and longevity 2.

For the fuel inlet fitting, the Plain Hose Coupling is used to connect the fuel lines to the engine’s fuel system. This connection must be robust and leak-free to ensure that fuel is delivered efficiently and safely to the engine, preventing any potential hazards associated with fuel leaks 3.

Lastly, in fuel plumbing systems, the Plain Hose Coupling is employed to join various sections of fuel lines. This ensures a continuous and secure pathway for fuel flow, which is essential for the consistent performance of the engine. The coupling helps in maintaining the pressure integrity of the fuel system, thereby supporting efficient combustion and engine operation 4.

Conclusion

The Cummins 3955171 Plain Hose Coupling is a vital component in the fluid transfer systems of commercial trucks. Its durable construction, ease of installation, and reliable performance make it an essential part for maintaining the efficiency and safety of these vehicles. Regular maintenance and proper installation are key to ensuring the longevity and optimal performance of this Cummins part.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ ↩ ↩ ↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ ↩ ↩ ↩ ↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩ ↩ ↩ ↩ ↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.